Often Purchased With

-

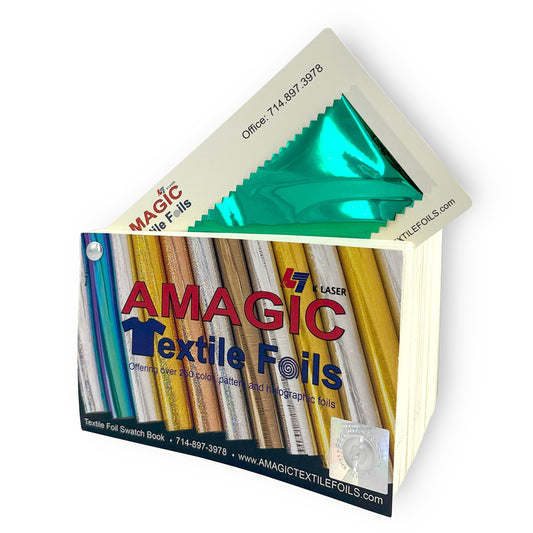

Amagic Textile Heat Press Foil For Screen Printing Swatch Book

ATF-ASBRegular price $95.00 CADRegular priceUnit price per$0.00 CADSale price $95.00 CAD -

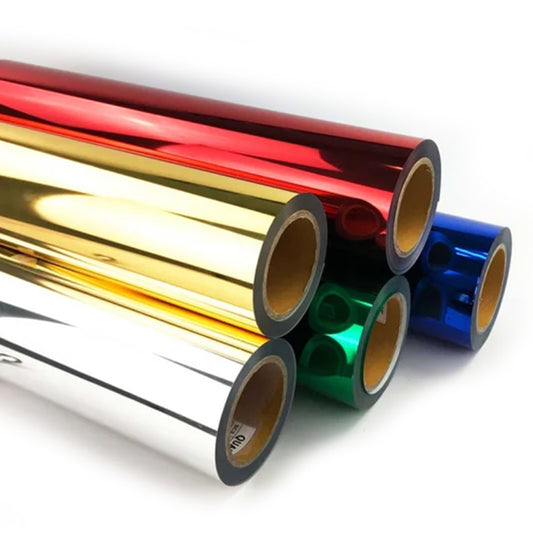

Amagic Textile Heat Press Metallic Foil For Screen Printing

ATF-B3Regular price $59.00 CADRegular priceUnit price per$59.00 CADSale price $59.00 CAD -

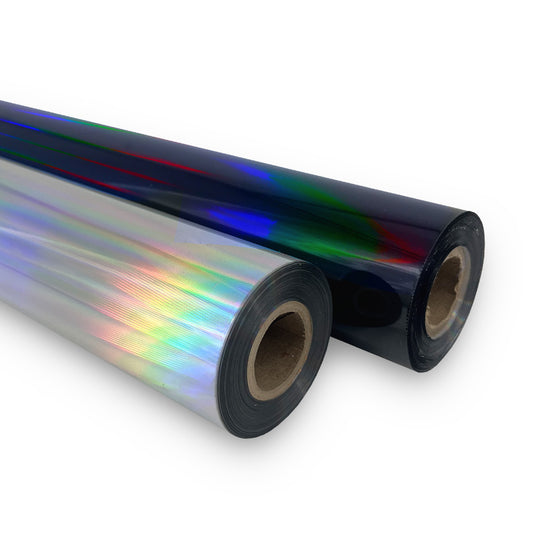

Amagic Textile Heat Press Holographic Foil For Screen Printing

ATF-K2ZP02Regular price $240.00 CADRegular priceUnit price per$0.00 CADSale price $240.00 CAD -

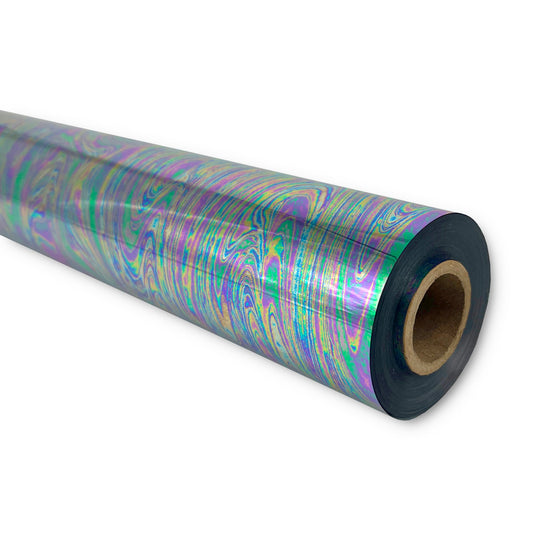

Amagic Textile Heat Press Pattern Foil For Screen Printing

ATF-S0LS01Regular price $215.00 CADRegular priceUnit price per$0.00 CADSale price $215.00 CADSold out -

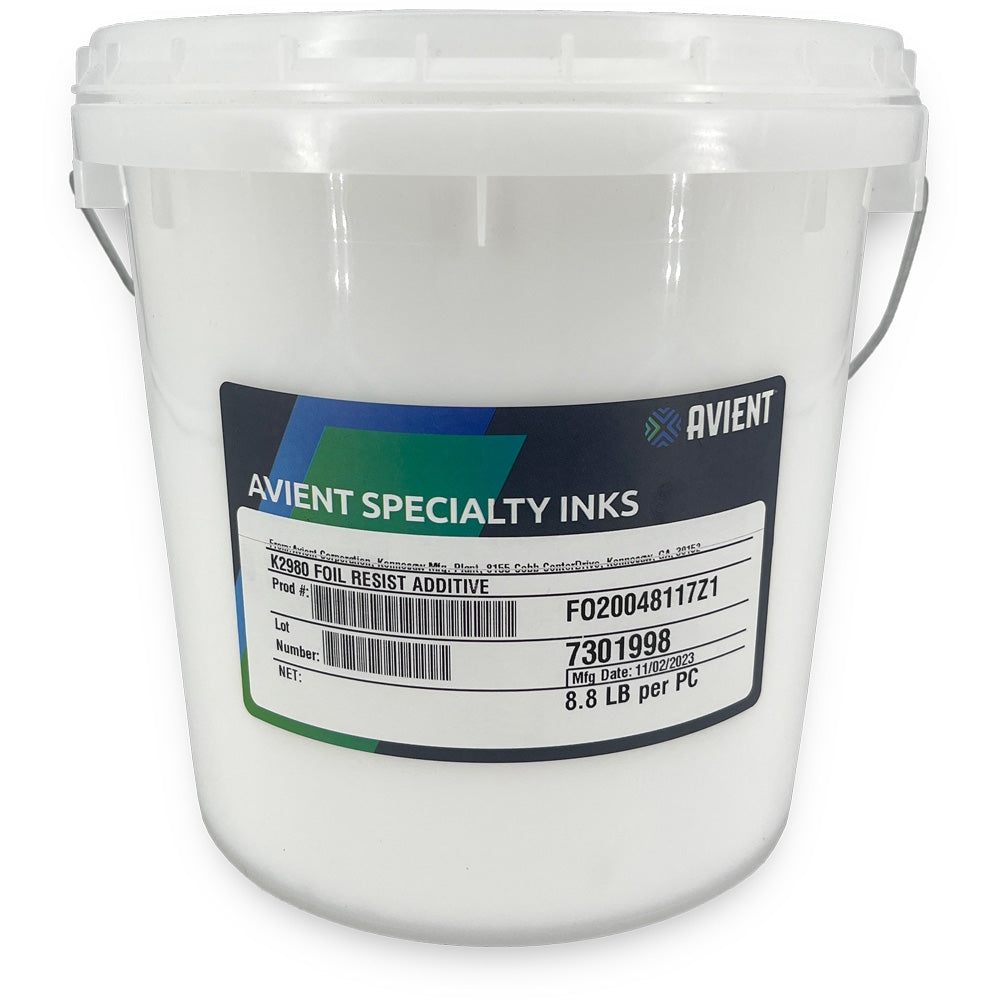

K2984 Infinite FX Foil Adhesive

FO20048891Z1Regular price $287.00 CADRegular priceUnit price per

Additional Information

- Works with a variety of fabrics and plastisol inks, excluding white inks.

- Effectively resists foil adhesion.

- Easily mixes into plastisol inks.

- Produces a soft, smooth surface.

Fabric Types

- 100% cotton, cotton/poly blends

Mesh

- Counts: 86-305 t/in (34-120 t/cm)

- Tension: 25-35 n/cm2

Squeegee

- Durometer: N/A

- Profile: N/A

- Stroke: N/A

- Angle: N/A

Stencil

- N/A

- Off Contact: 1/16” (2mm) or greater

- Emulsion Over Mesh: N/A

Flash & Cure Temperatures

- Flash: N/A

- Cure: N/A

Pigment Loading

- N/A

Additives

- N/A

Shipping & Storage

- 65-90°F (18-32°C)

- Avoid direct sunlight.

- Use within one year of receipt

Clean Up

- Unused ink will need to be disposed of responsibly. Standard plastisol cleaners, press wash, or ink degradant

- Mix up to 10% by weight into plastisol inks.

- Ensure that K2980 Foil Resist Additive is thoroughly mixed into ink(s) before printing.

- Inks mixed with K2980 Foil Resist Additive can also be used for non-foil printing applications.

- When possible, print and flash foil adhesive inks before printing foil resist colors. Printing foil resist colors last in the sequence will reduce exposure to flash heat and adhesion to other screens.

- Colors mixed with K2980 Foil Resist Additive should be printed wet-on-wet whenever possible to reduce the potential of overheating the ink.

- Stir plastisols before printing.

- Do not dry clean, bleach or iron printed area.

- Perform fusion tests before production. Failure to cure ink properly can result in poor wash fastness, inferior adhesion and unacceptable durability. Gel and cure temperatures for ink should be measured using a Thermoprobe device placed directly in the wet ink film and verified on the substrate(s) and equipment to be used for production.

- It is the responsibility of the printer to determine that the correct ink has been selected for a specific substrate and the application processes meet the printer’s customer standards or specifications.

- Curing is the responsibility of each printer to confirm that the print is fully cured. PolyOne’s cure recommendations are not a guarantee or warranty, but merely suggested starting points for curing evaluations as explained above.

- When printing on garments that contain certain dyes, you must pre-test for the potential ghosting. Please refer to our website for more information on this issue.

- Wilflex products have been carefully designed to perform within a given viscosity range, and any dramatic change in viscosity is probable to result in a change in printing characteristics

- NON-CONTAMINATION OF EPIC INKS: Do not mix EPIC inks with inks, additives or extenders from other companies. All buckets, palette knives, stirring apparatus, squeegees, flood bars and screens must be cleaned properly and free of phthalates and pvc containing inks. Non-phthalate emulsions and pallet adhesives must be used. Failure to follow these precautions may cause phthalate contamination in violation of consumer protection laws and regulations.

- Any application not referred in this product information bulletin should be pre-tested or consultation sought with Wilflex Technical Services Department prior to printing.