Often Purchased With

-

Kodacolor FTF Film (13" x 19" - 100 Sheets)

7494610-DTF1 pack @ $110 CAD

10 packs @ $100 CAD / Pack

Sale -

Brother GTX Pro B

gtxpro-b -

-

Brother GTX 600

GTX600

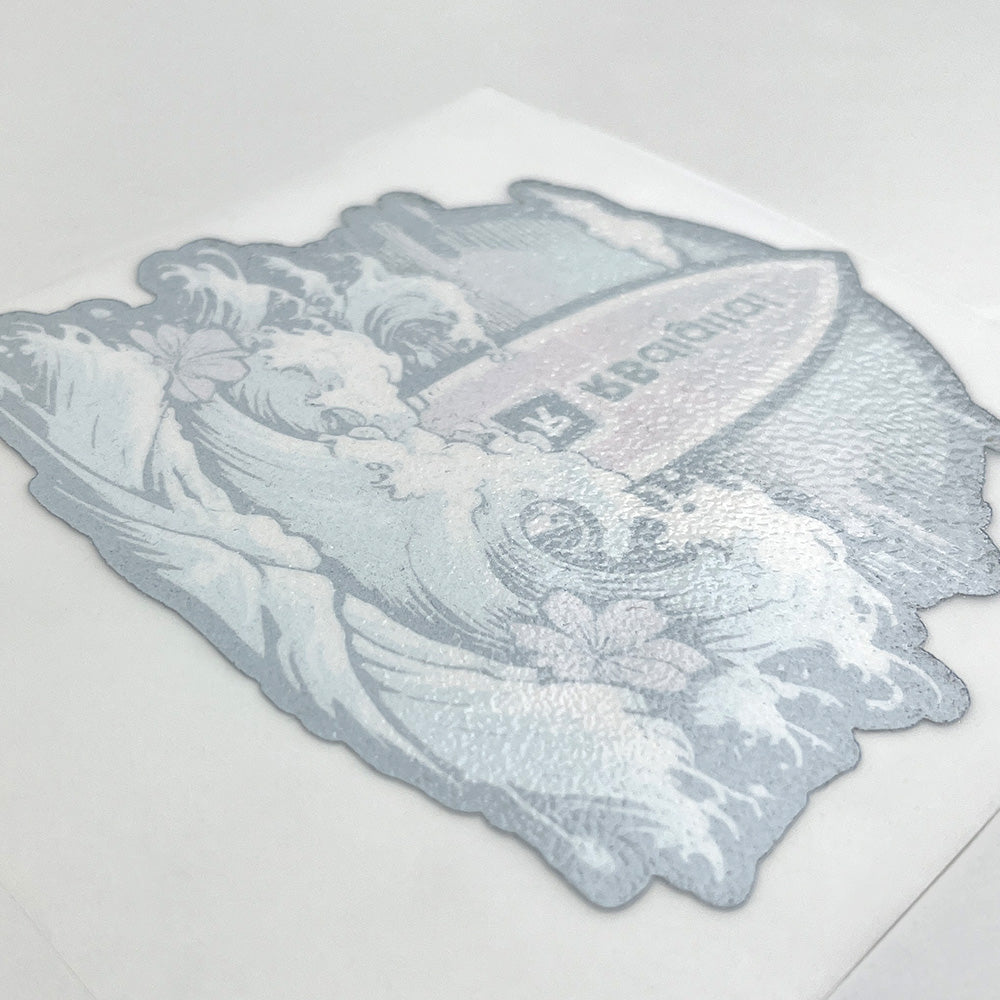

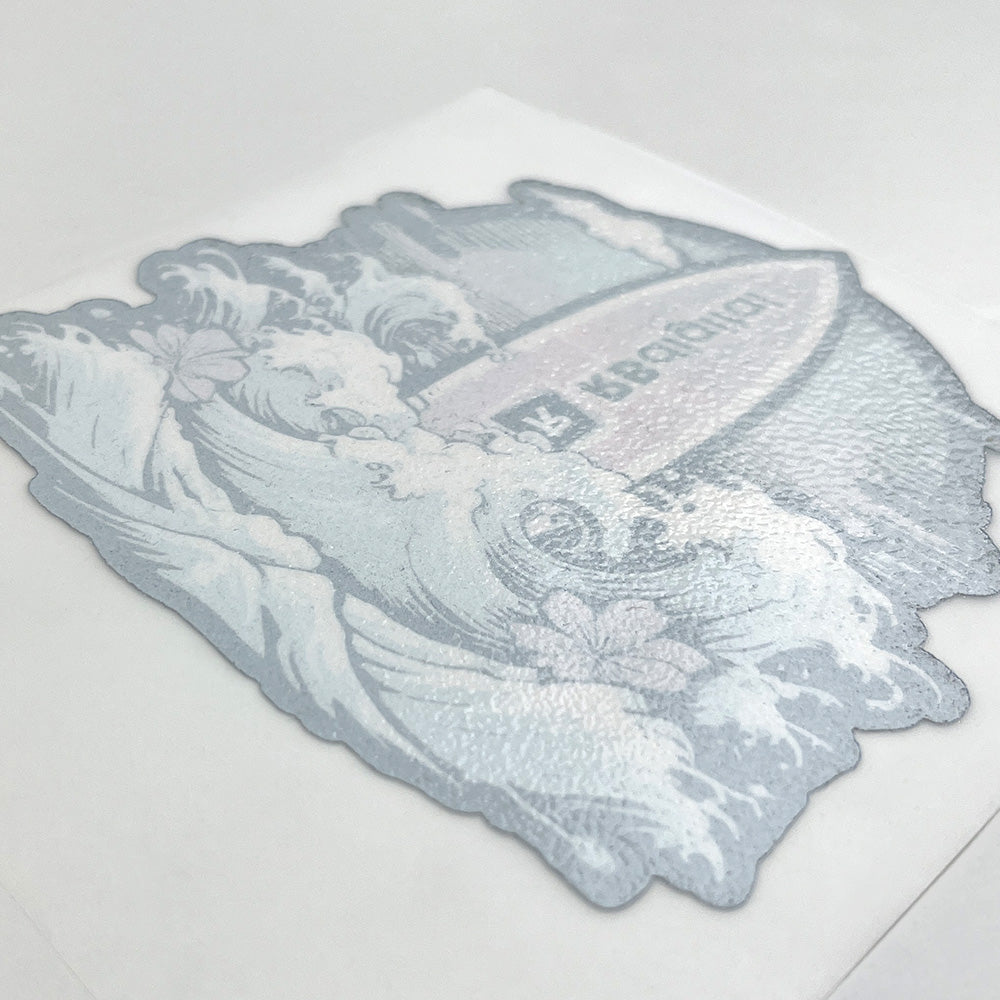

How To Achieve a Matte vs. Gloss Finish

With our RB DTF Hot Peel Film, you can achieve either a glossy or matte finish for your print, depending on how you apply the film to the shirt. For a matte finish, cover your print with silicone-coated parchment paper before pressing with your heat press. For a glossy finish, use a Teflon sheet or a heat press with a Teflon-covered top when heat pressing the film.

-

Matte Finish

-

Gloss Finish

Note: The samples provided are for reference only and may not accurately represent the film's true appearance. Color rendering can vary across monitors and screens, affecting the perceived effects. These images do not fully capture the film's quality, so we recommend seeing the results in person.

Additional Information

- Made in Korea

- Extra Ink Loading

- Anti - Static Treated

- Instant Hot Peel for Faster Production

- No Oil from the Film

- High Resolution

- Matte & Clean Finish

Film Structure |

Coating |

Thickness |

|---|---|---|

|

Top Coating |

Primer |

5 ~ 6 ㎛ |

|

Release Coating |

Primer |

4 ㎛ |

|

PET |

|

75 ㎛ |

| Back |

Anti-static threated |

1 ~ 2 ㎛ |

- Keep out of direct sunlight

- Avoid to use the film in high humidity (Recommended humidity : 50% below)

- Keep dry

- Do not use damaged film which could damage printers