Often Purchased With

-

AlbaChem VLR Vinyl Letter Removing Solvent

1020Starting at $20.41 CAD

-

Clean Cut Blades – Vinyl Cutter Blades

AGTK-45Regular price From $22.50 CADRegular priceUnit price per -

Poli-Flex 854 Mask

RBFLEX-854Regular price From $120.00 CADRegular priceUnit price per -

Poli-Flex Turbo Print - Printable Vinyl

RBFLEX-4036Regular price $473.00 CADRegular priceUnit price per

Additional Information

Washable at 60°C. For application to Nylon that is treated with any kind of coating, please test for suitability.

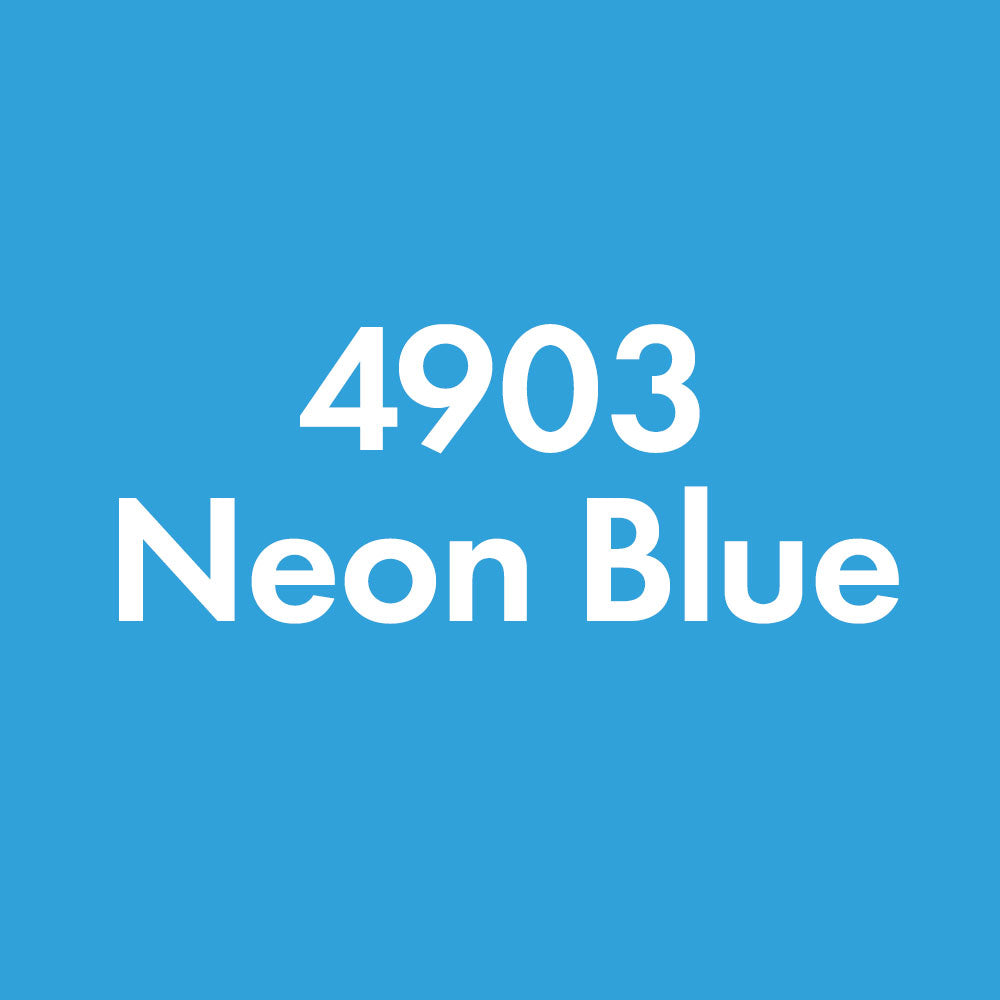

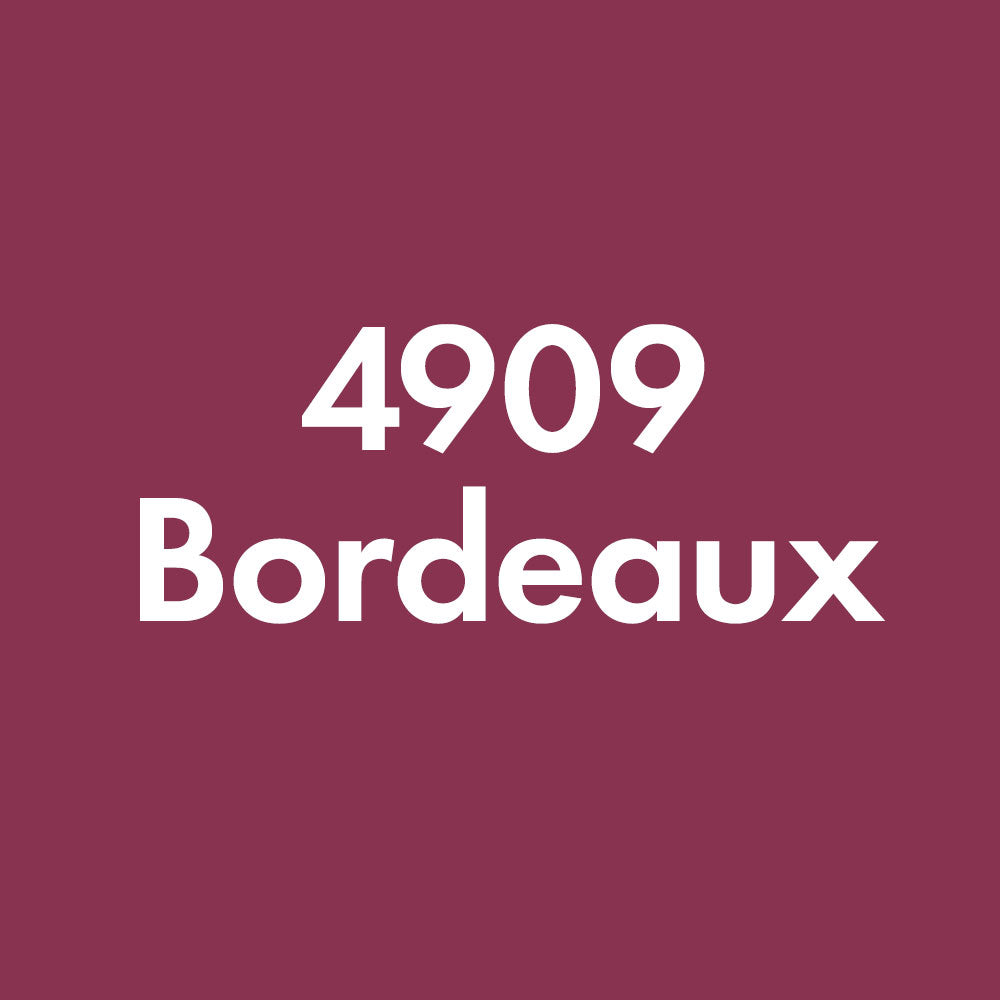

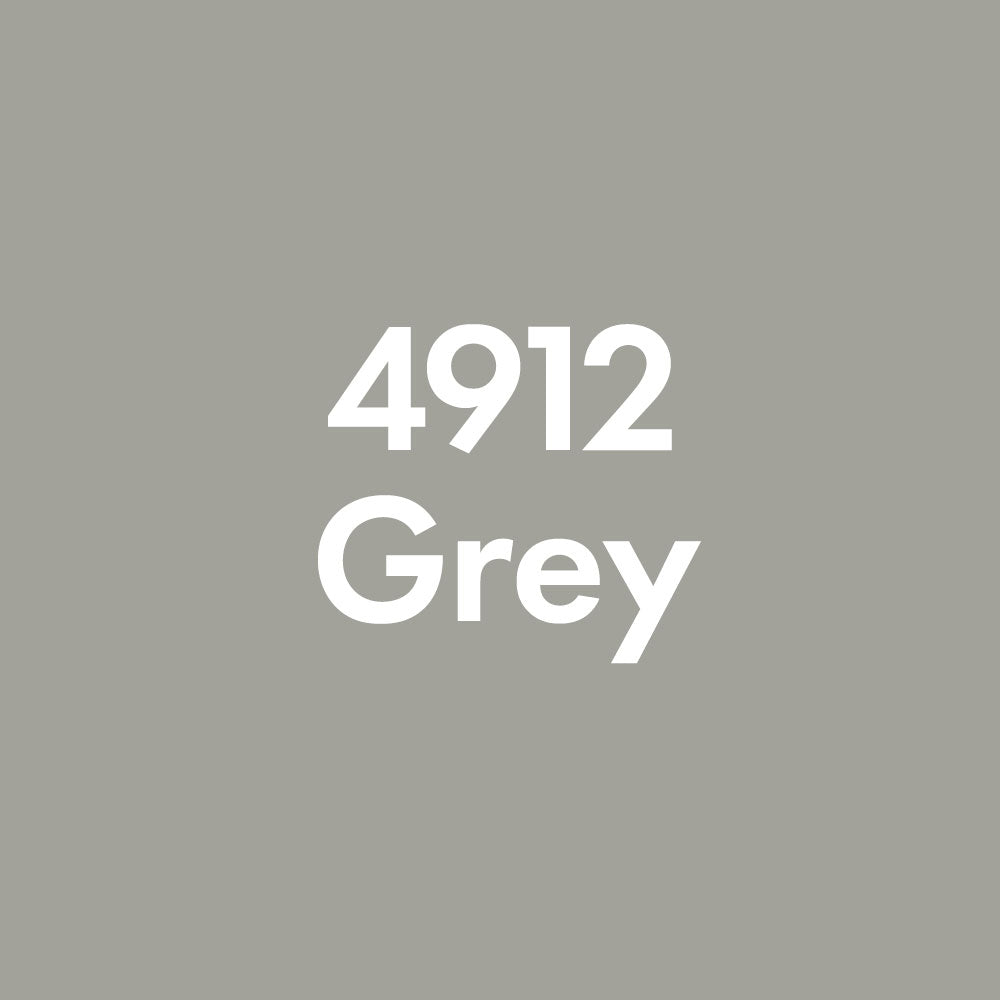

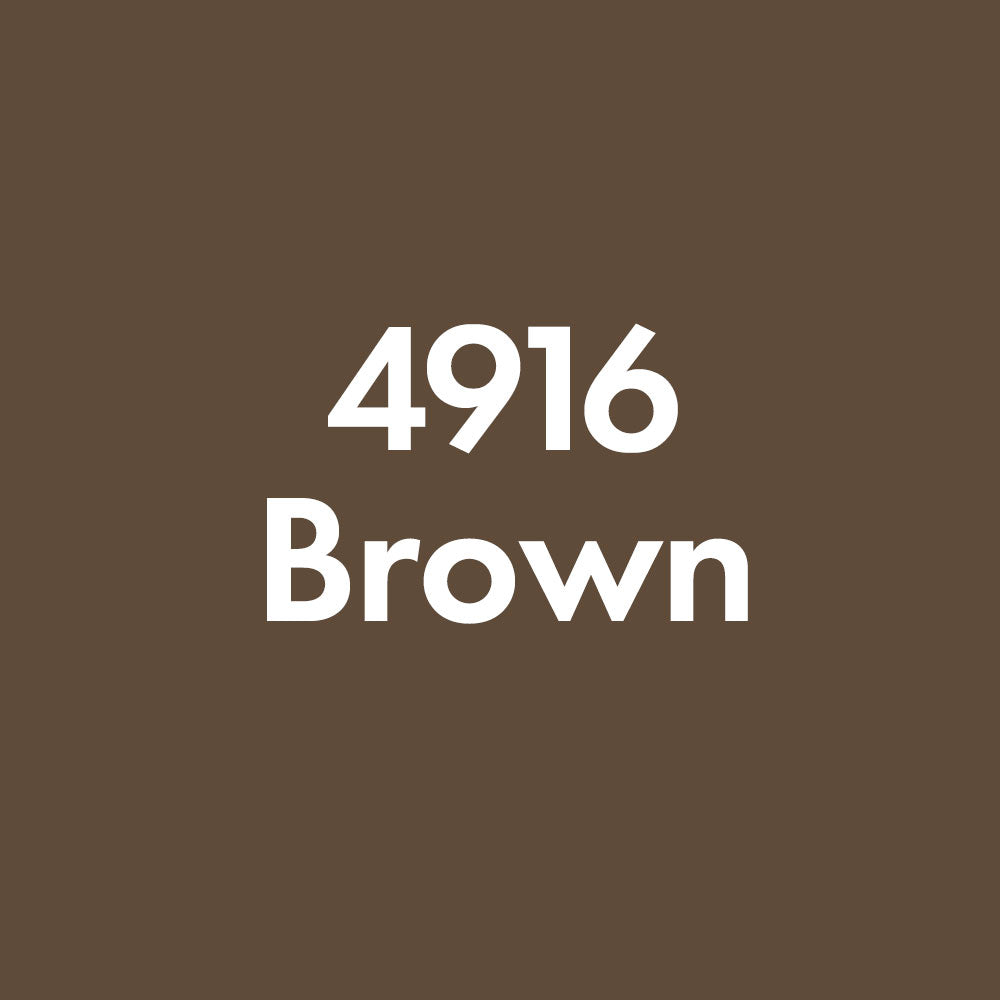

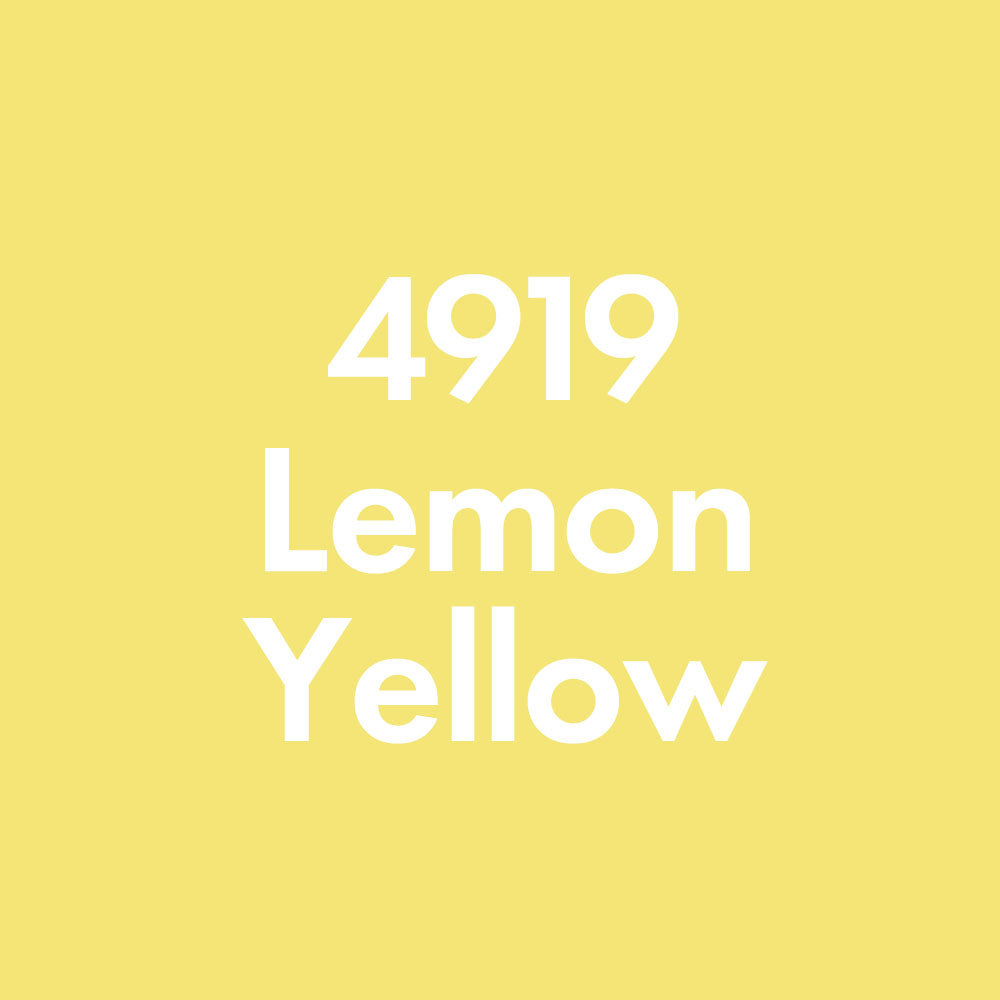

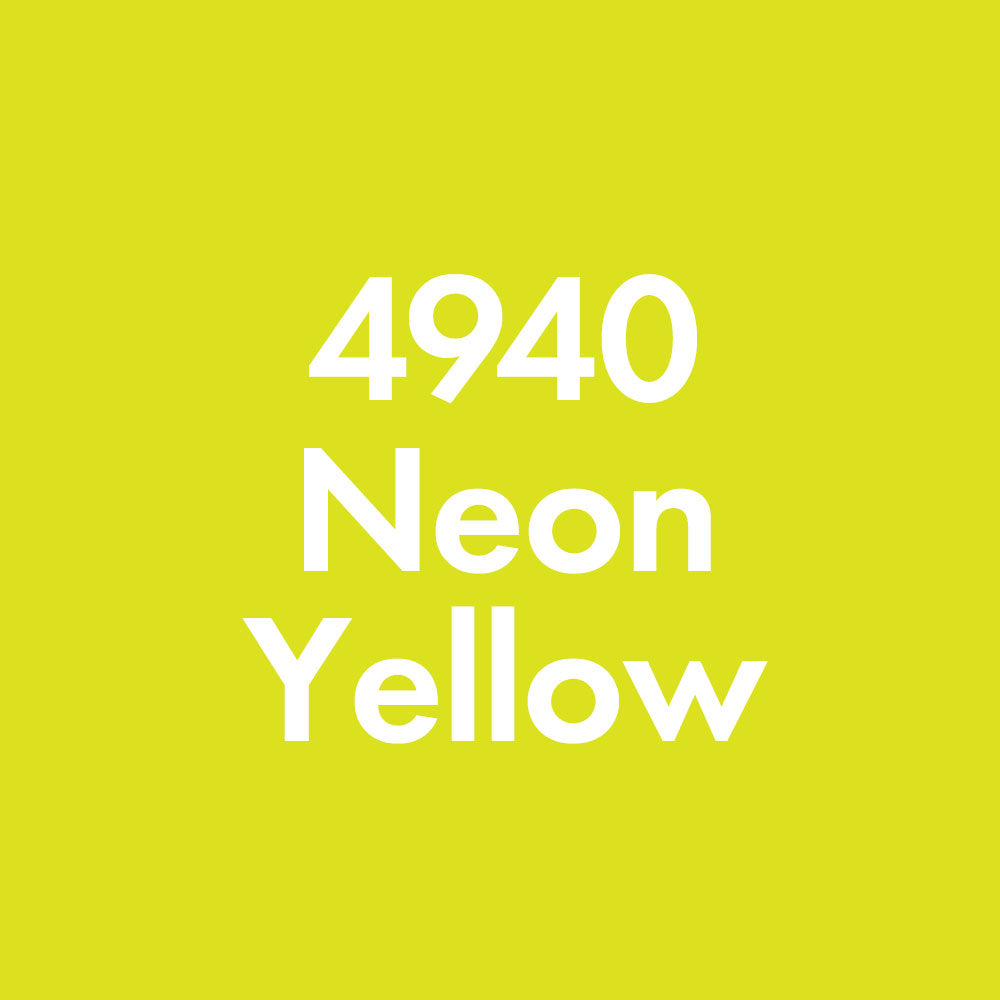

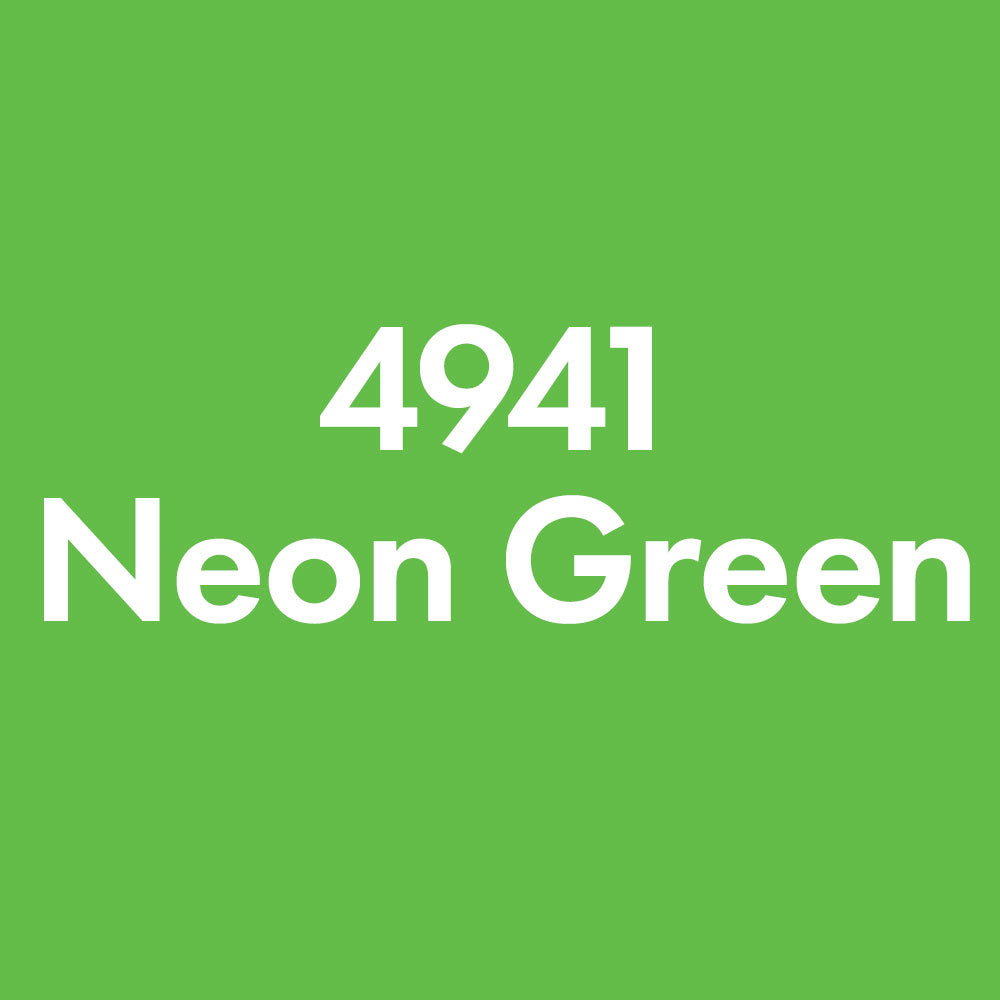

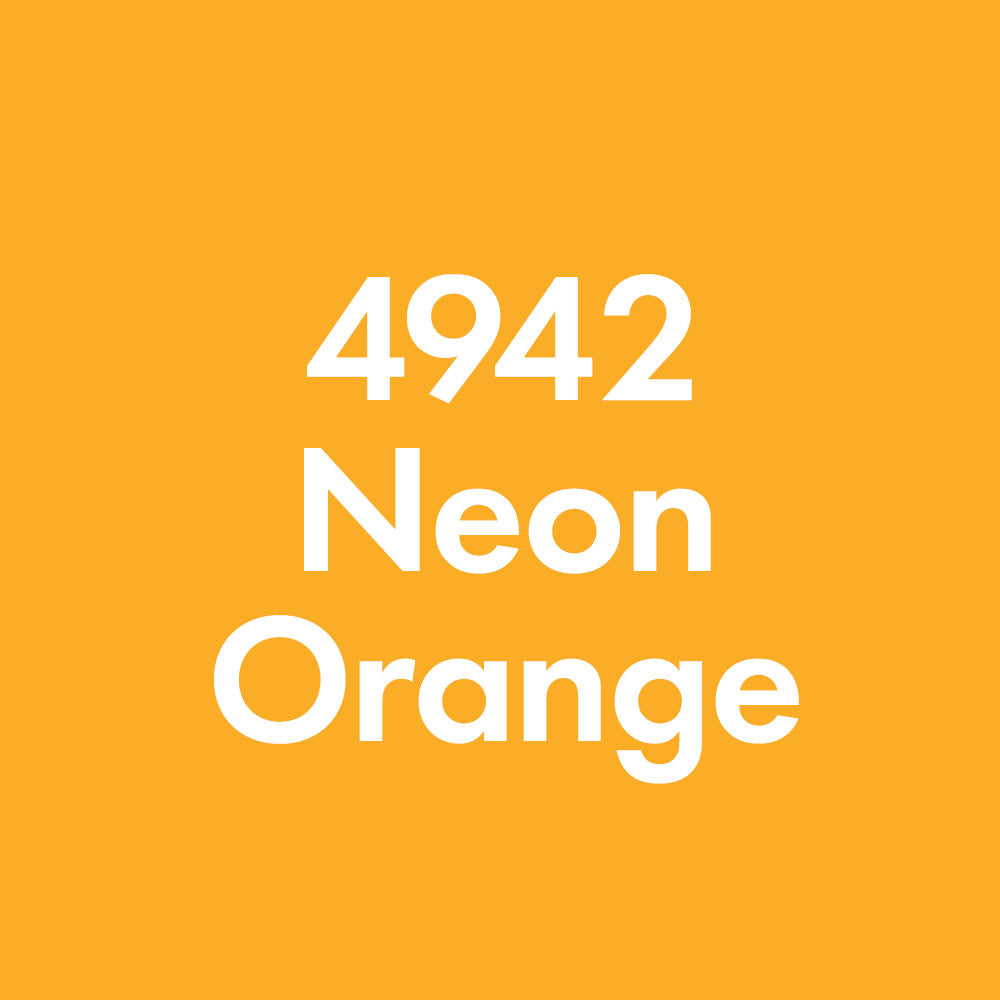

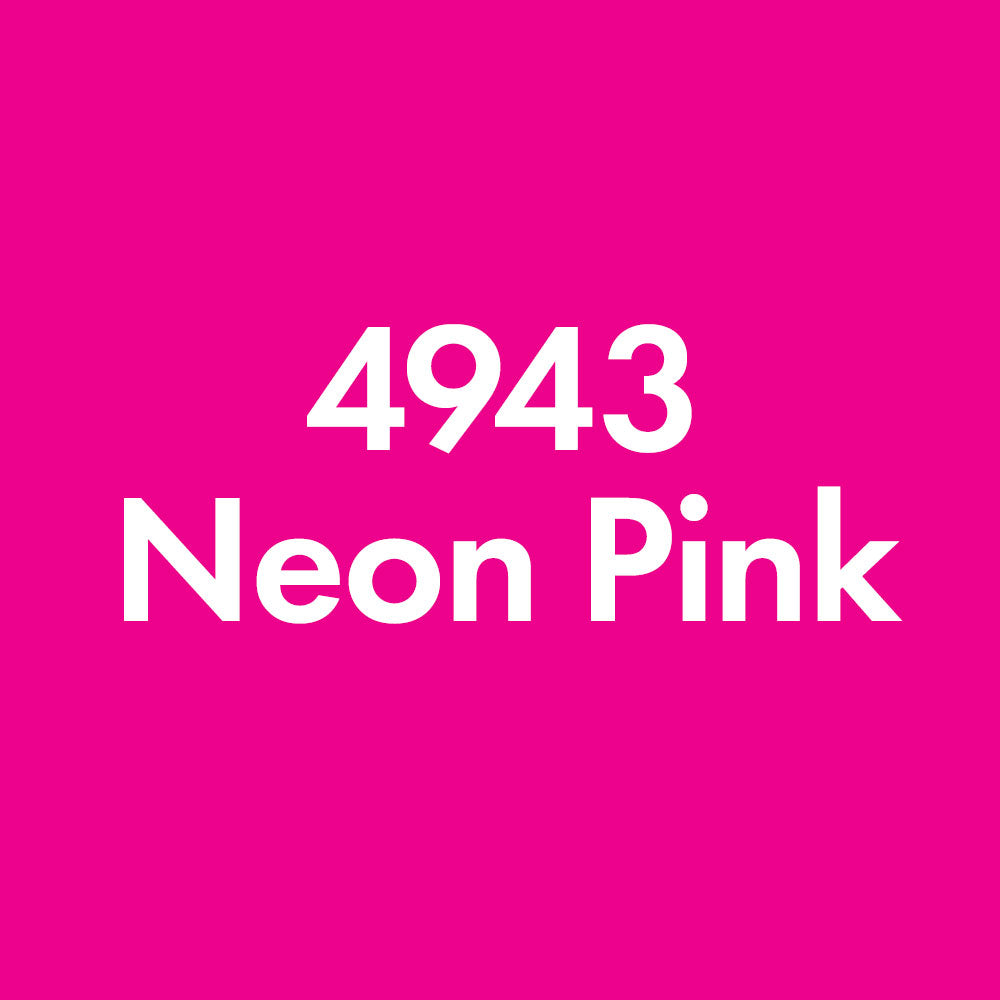

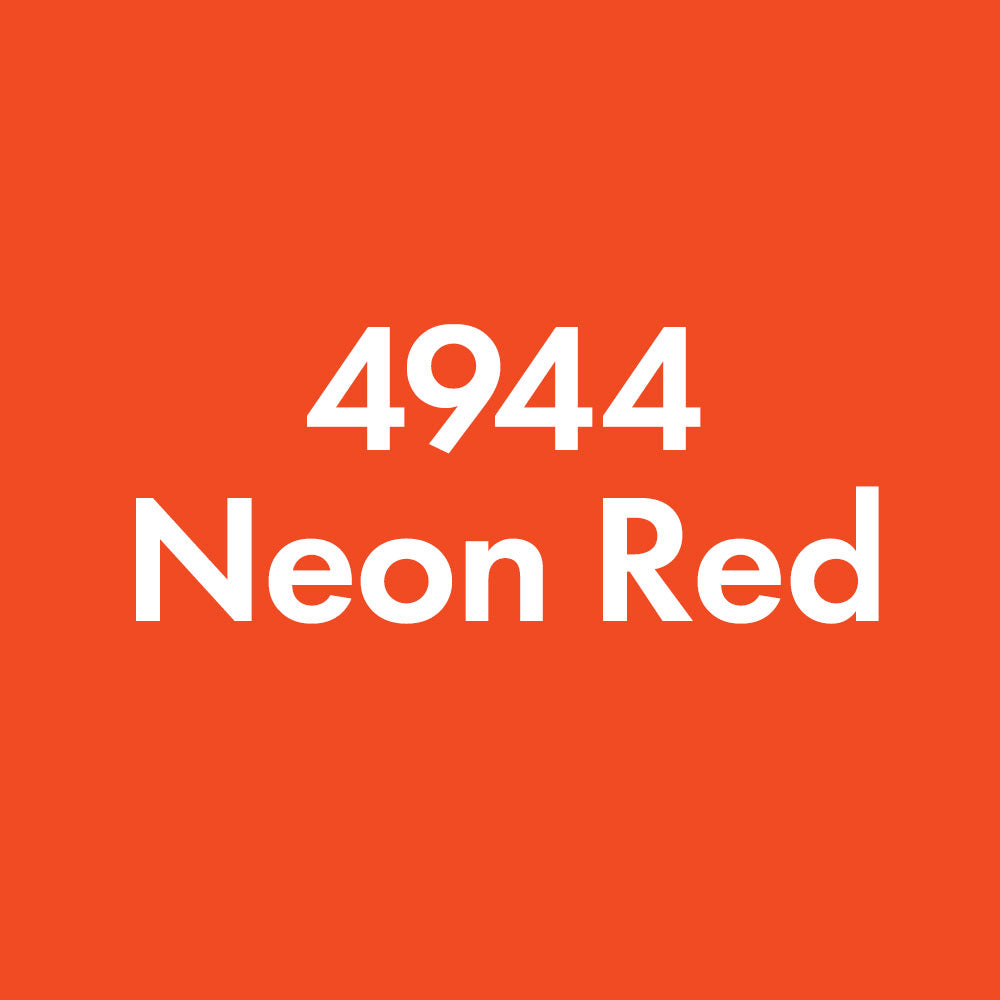

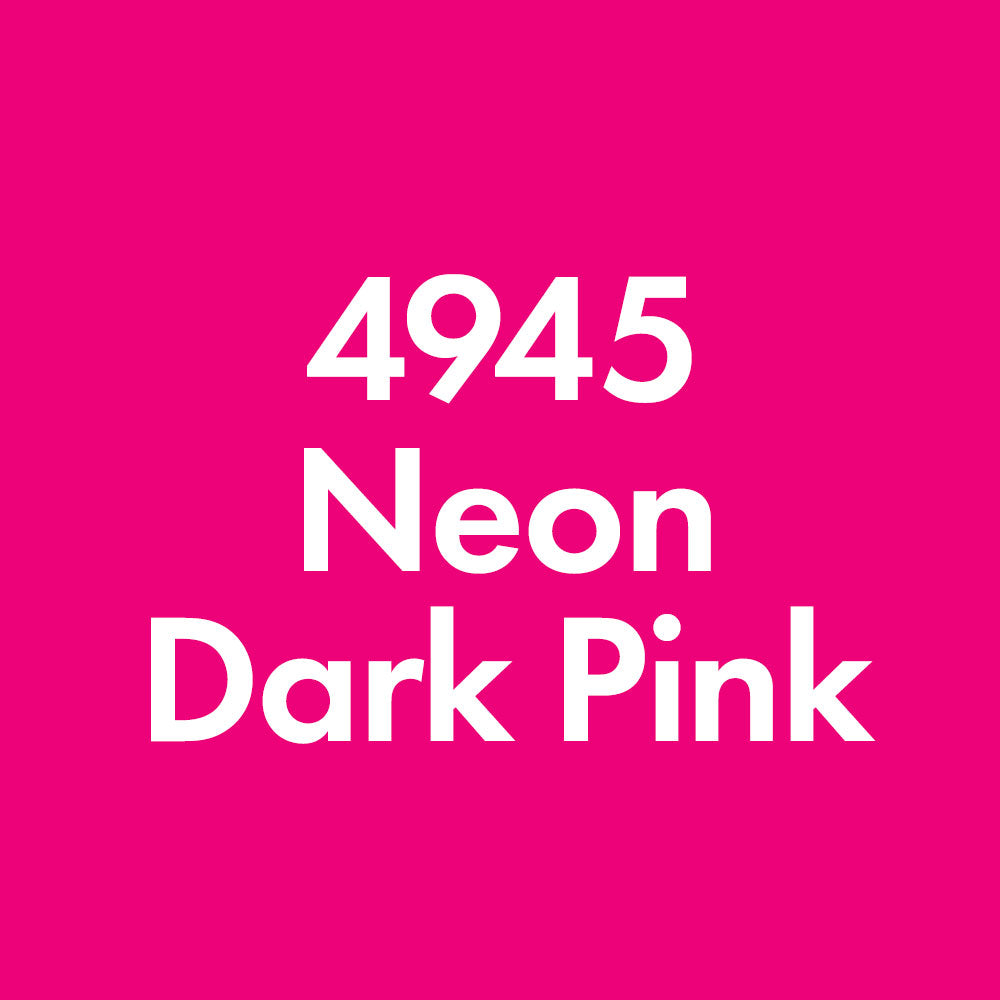

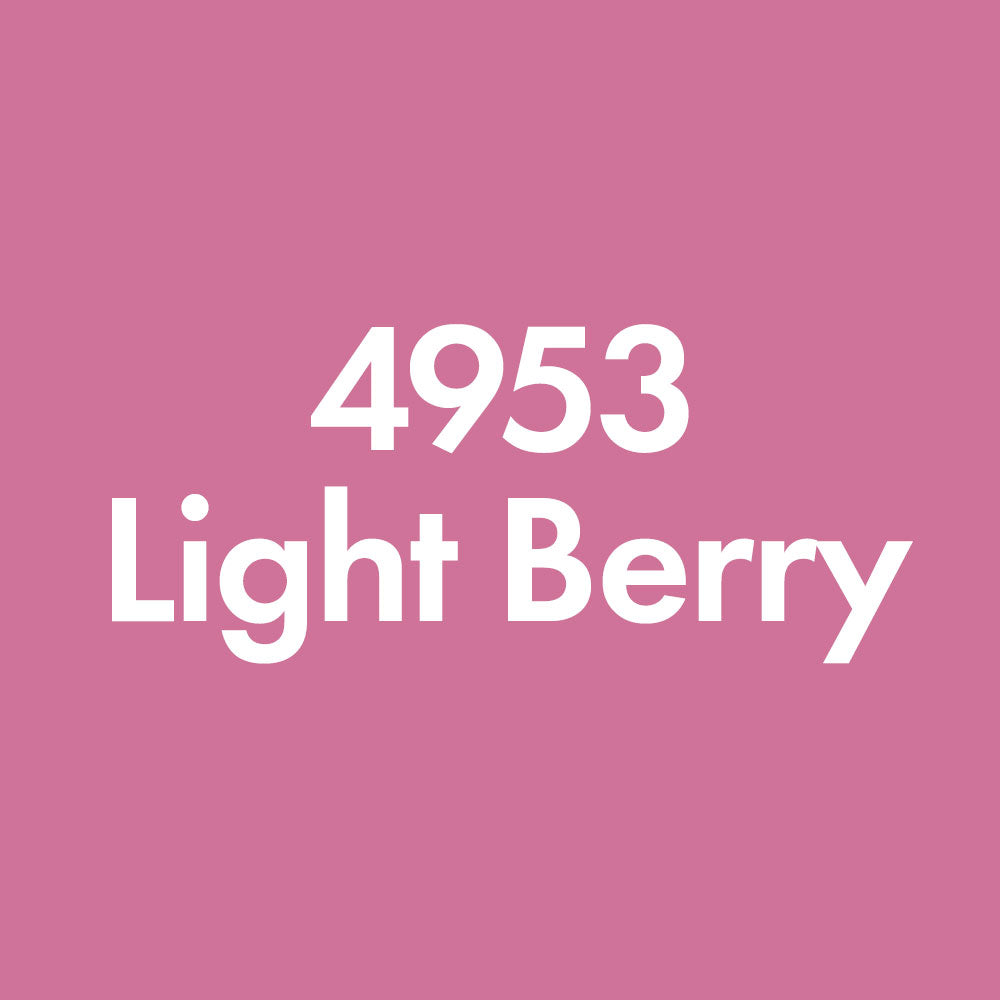

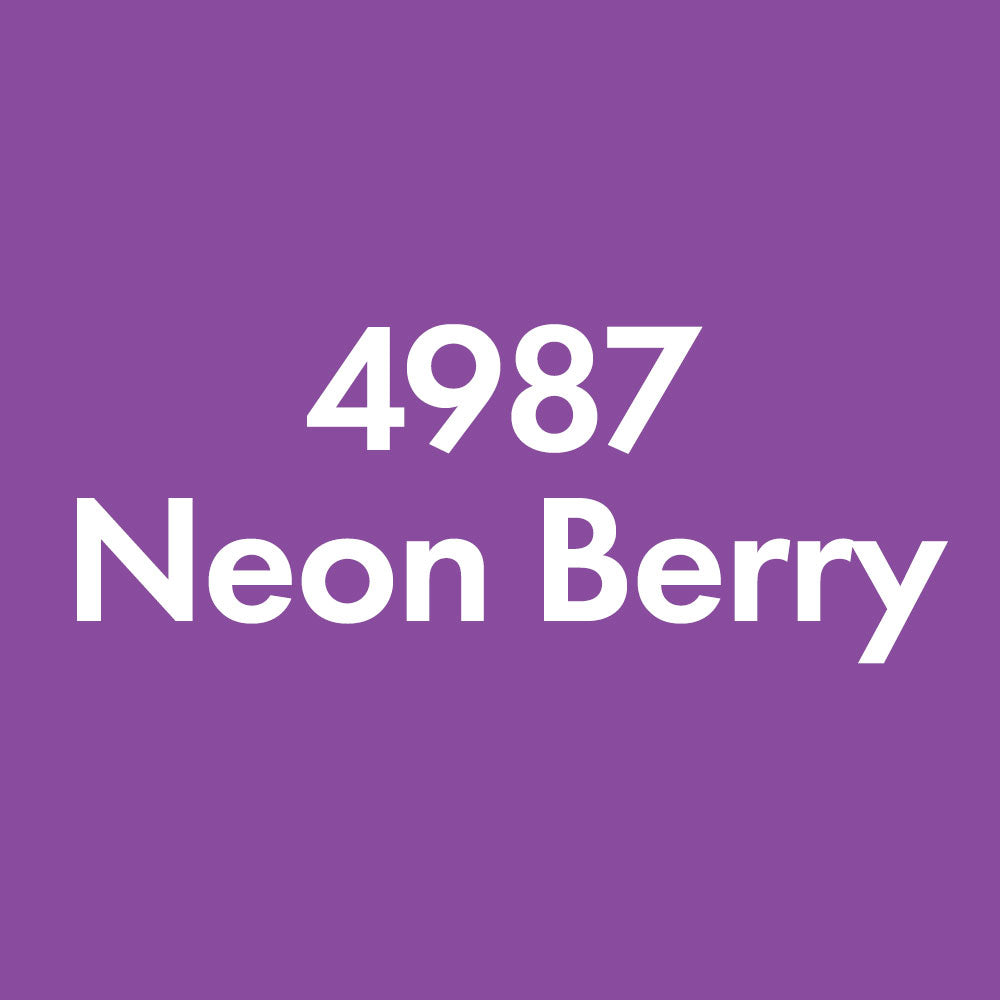

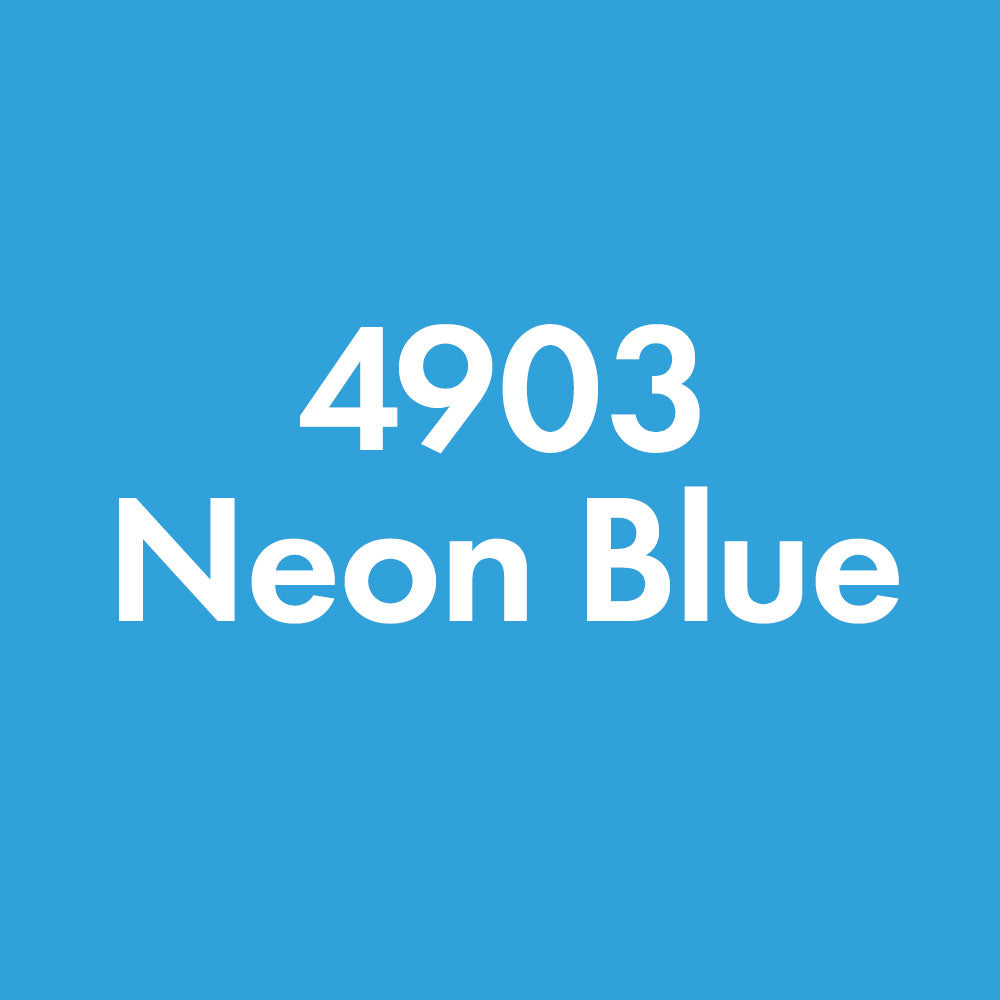

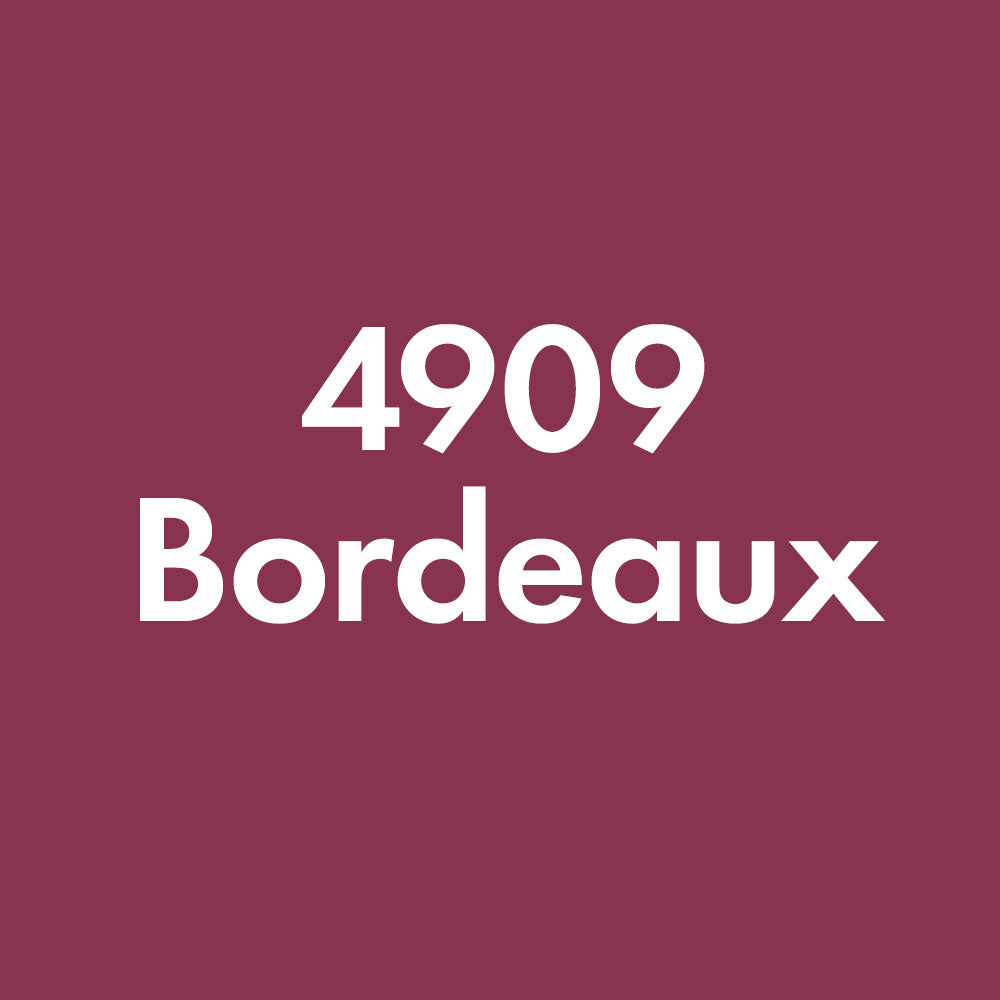

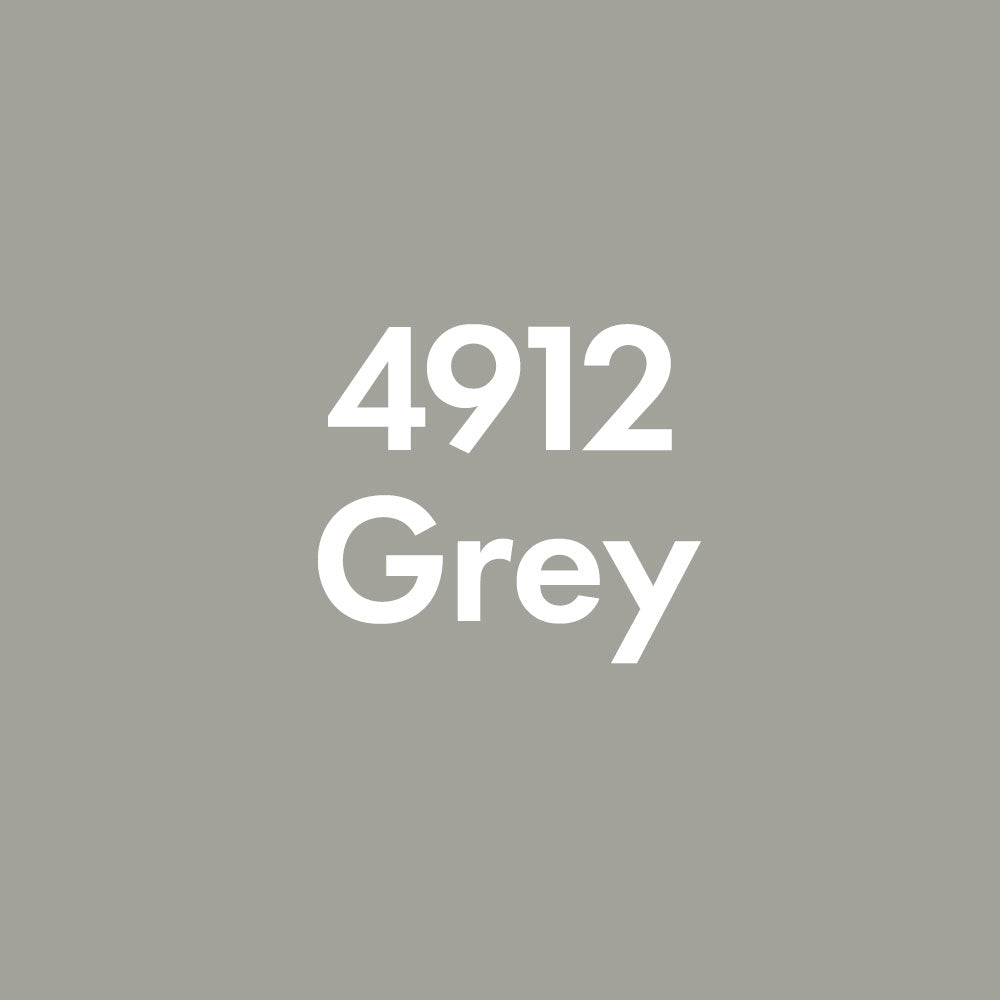

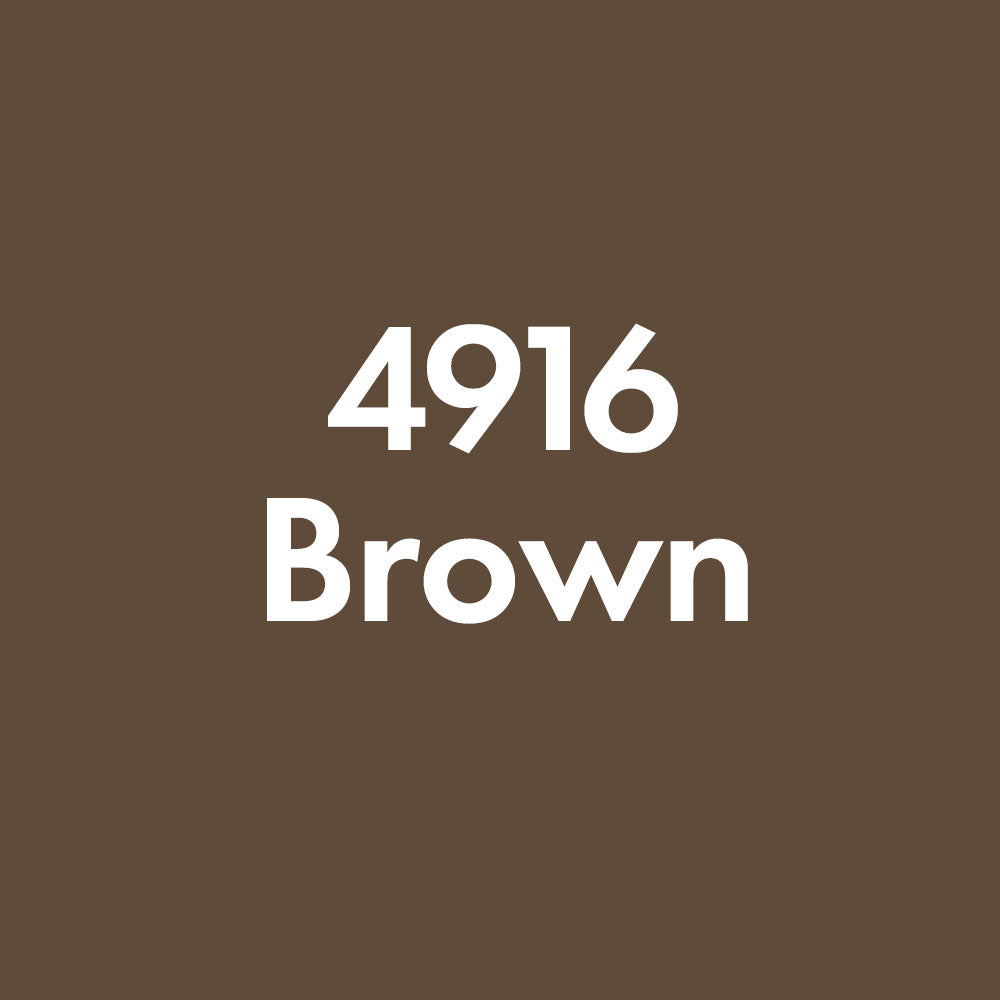

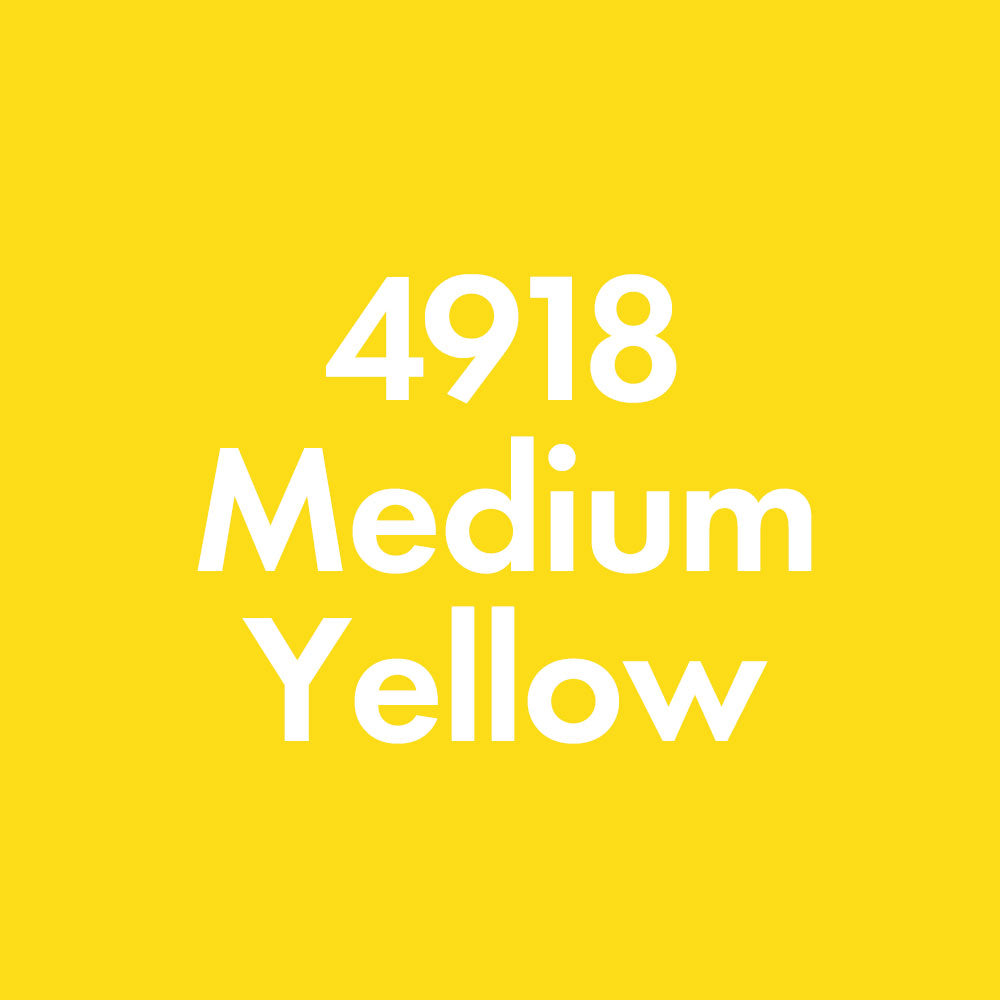

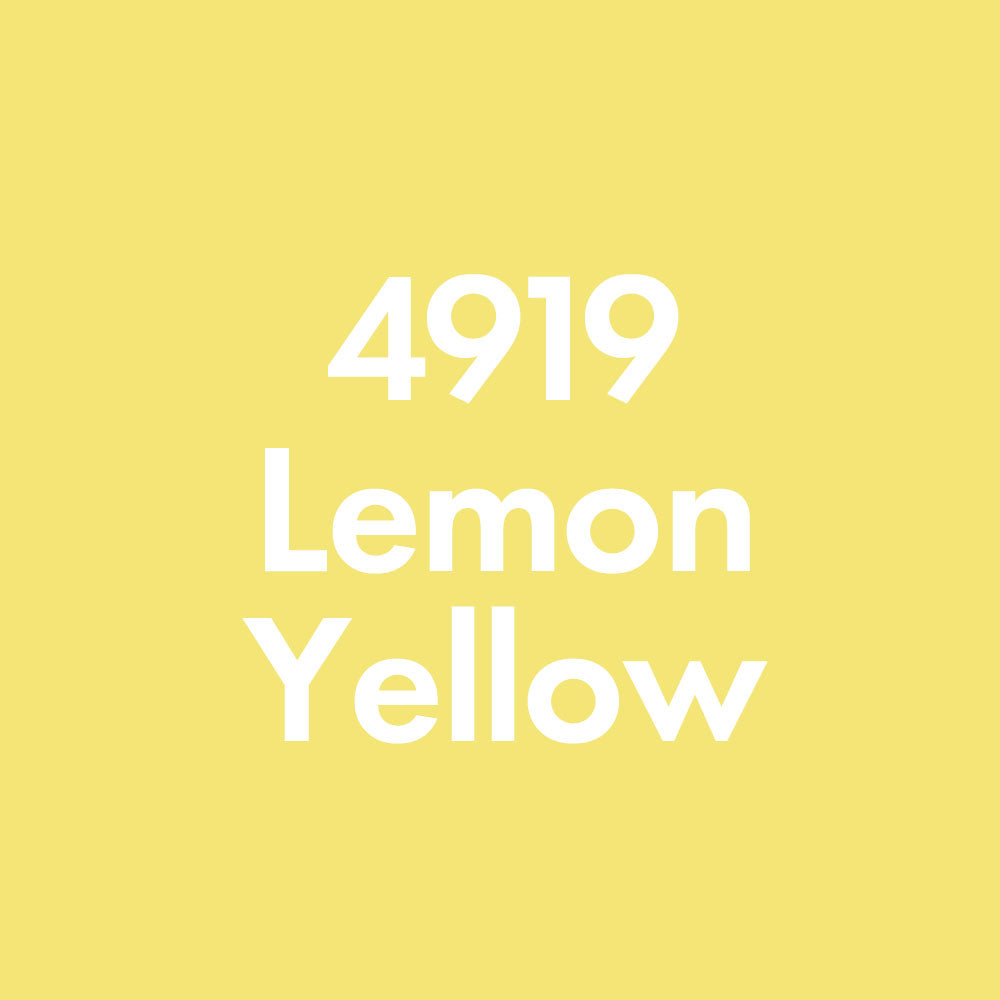

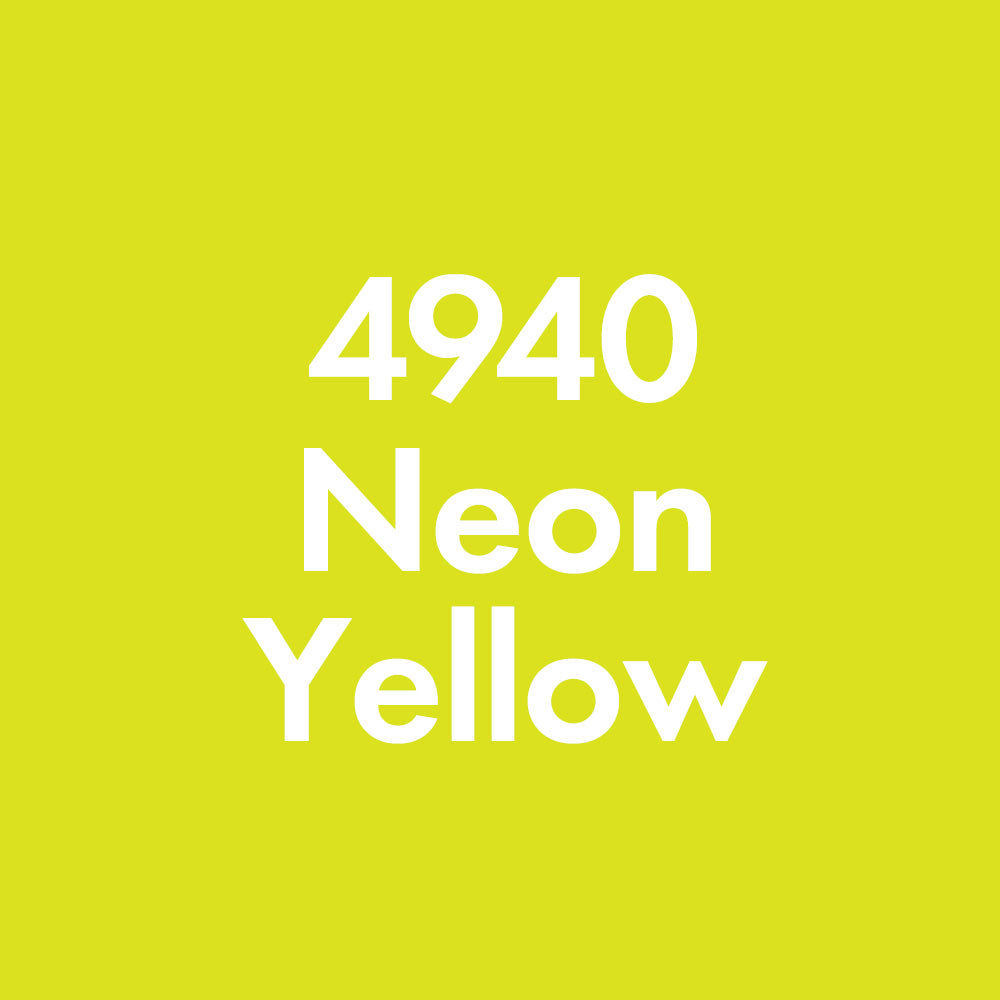

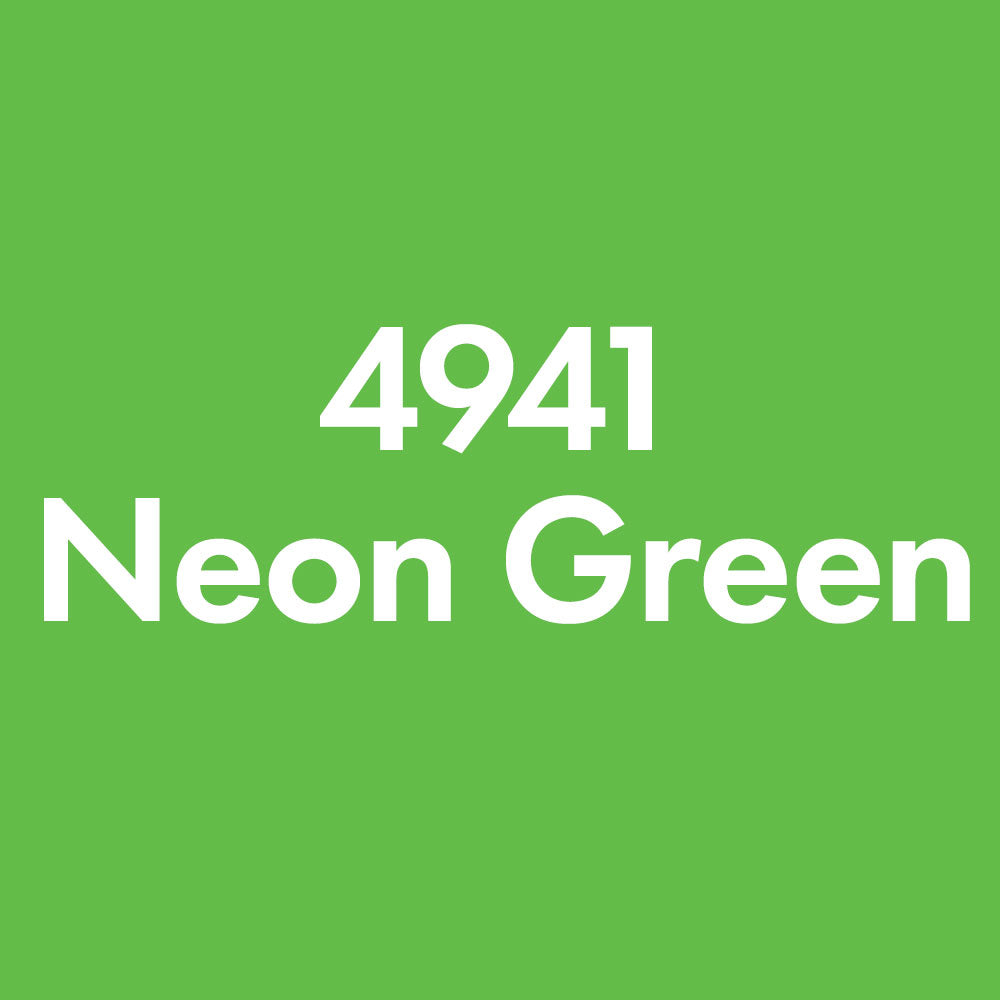

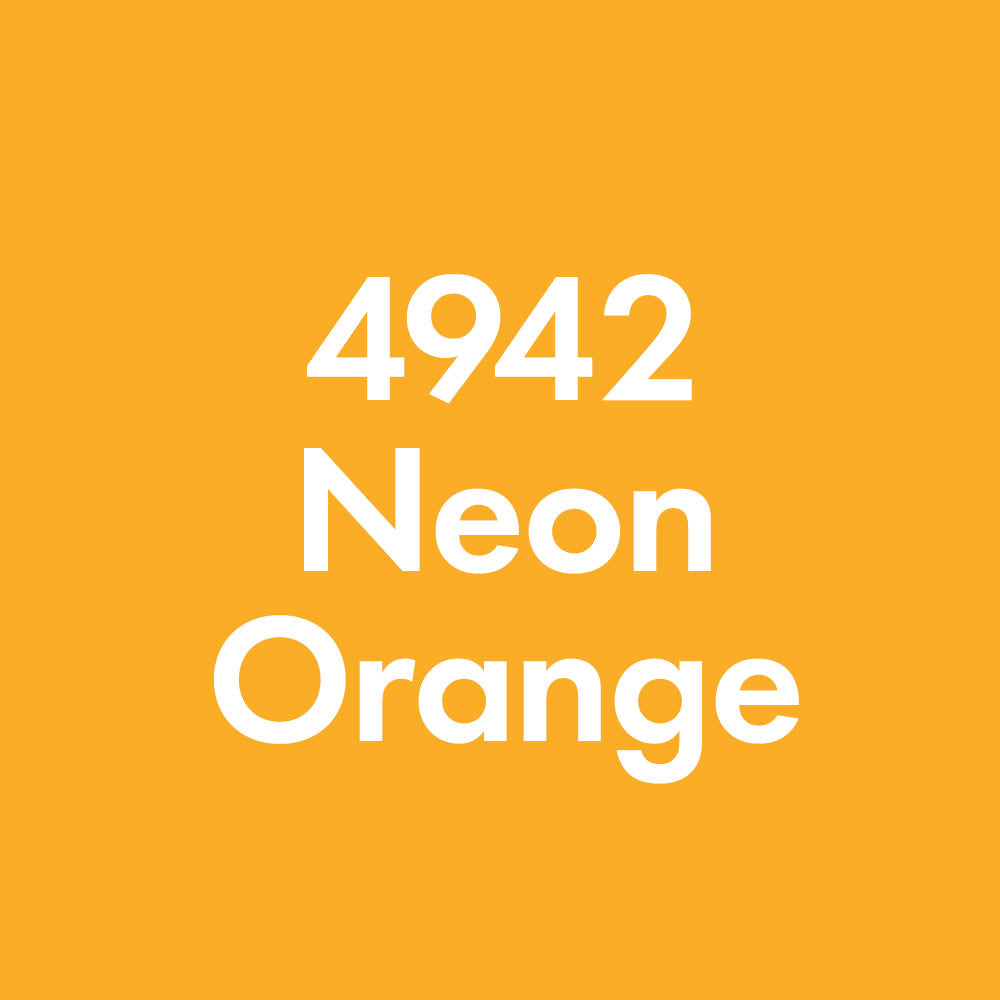

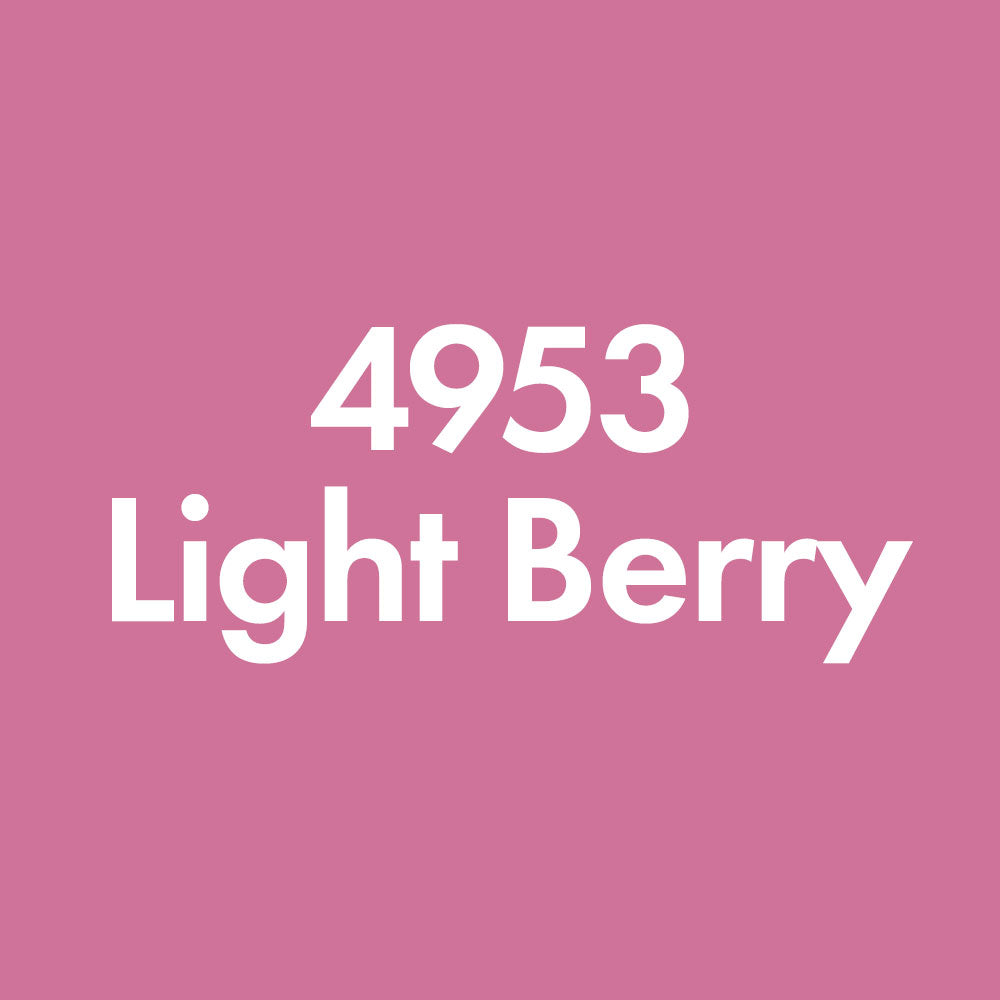

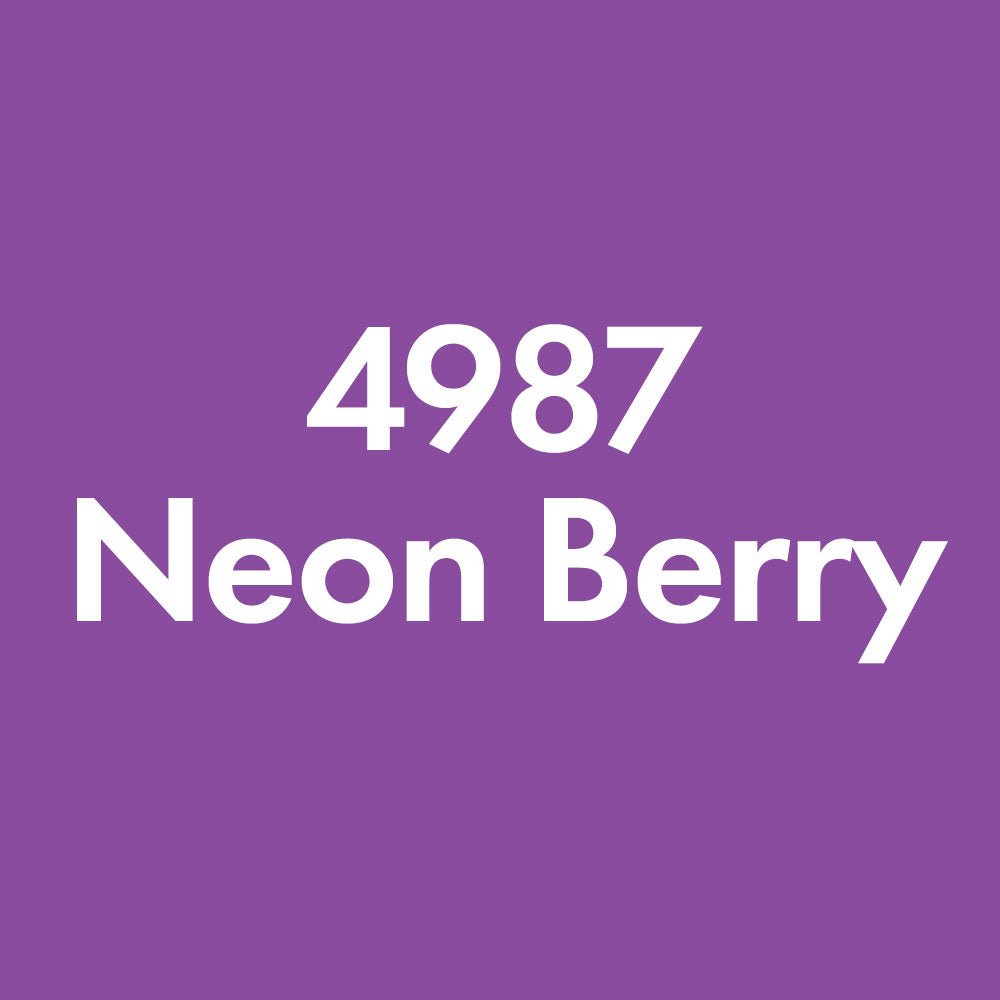

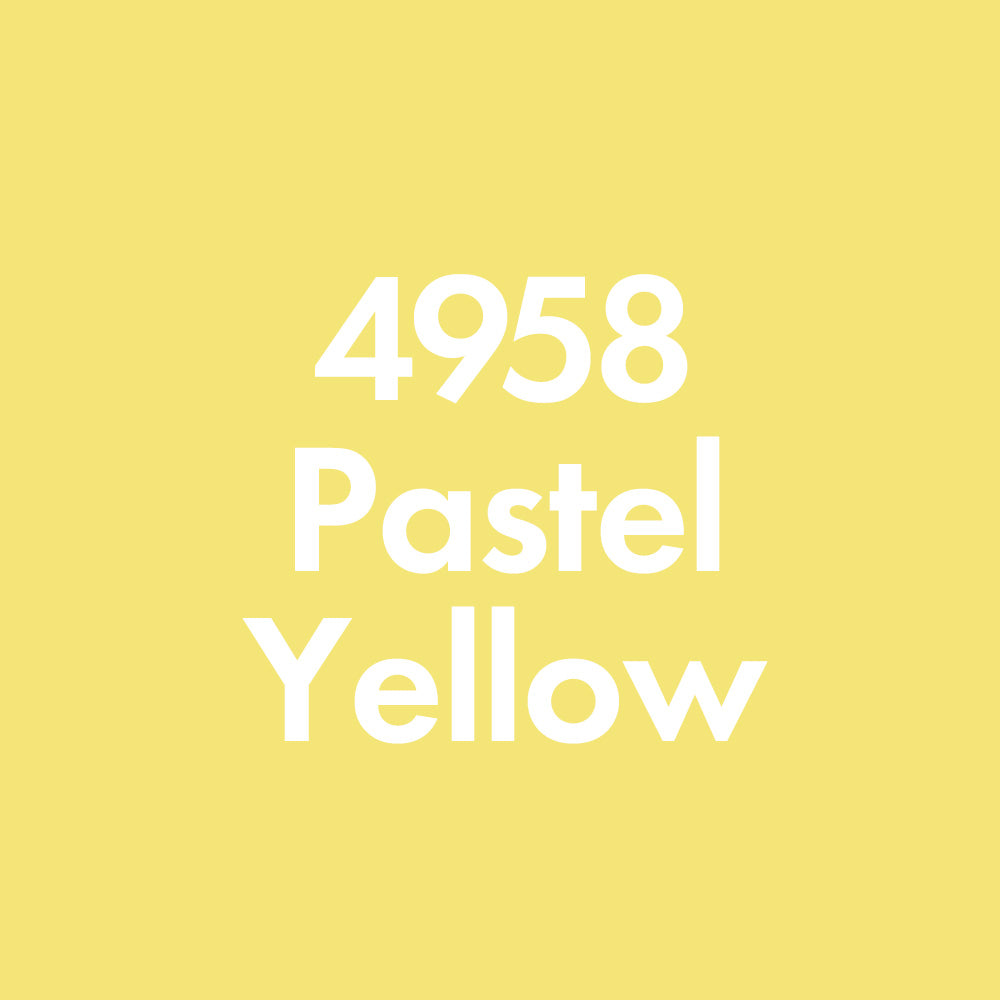

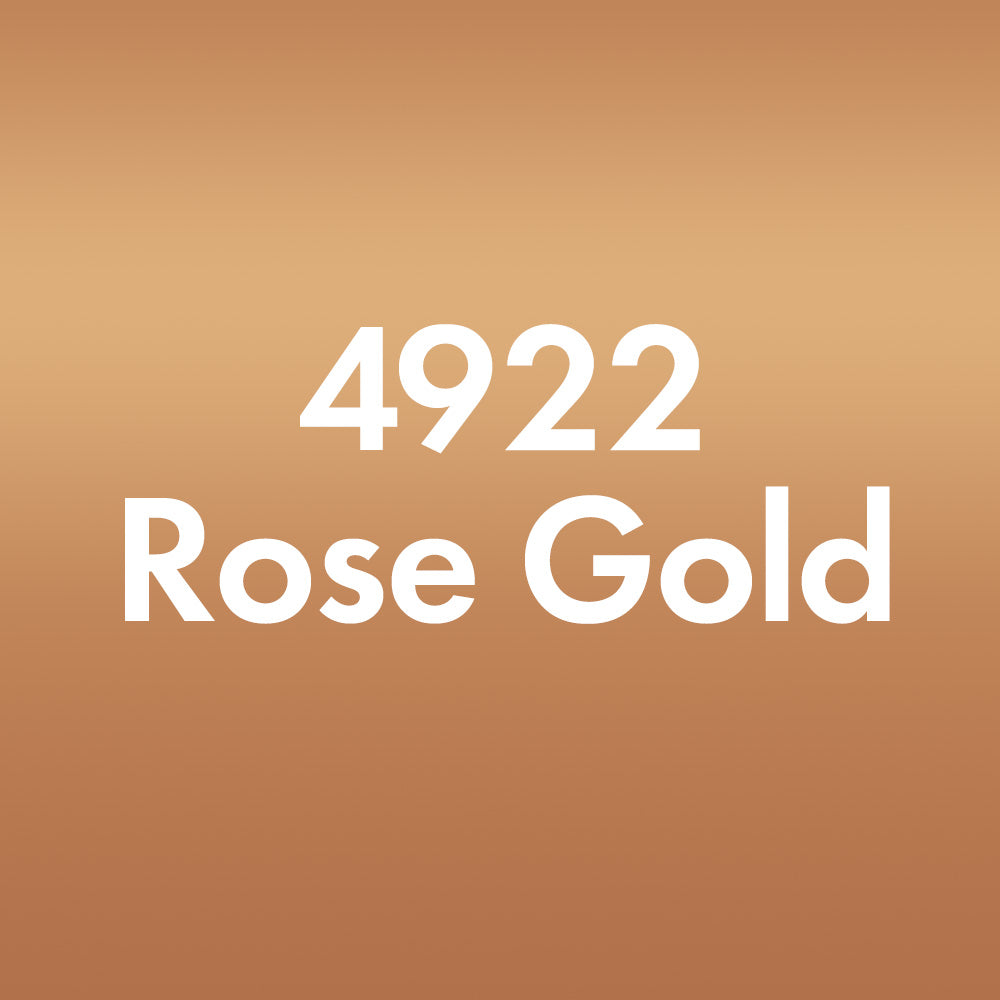

Guarantee for a secure and long-lasting bond of POLI-FLEX® TURBO is only given when following the specified temperature and pressure conditions. With the exception of 4920 Gold Metallic, 4930 Silver Metallic and the Neon colours (4903, 4940 – 4943), the POLI-FLEX® TURBO series can be pressed on top of each other. We recommend evaluation on test material.

The soft, elastic carrier film offers a comfortable textile touch and convinces due to high wearing comfort. POLI-FLEX® TURBO excels due to an excellent opacity. POLI-FLEX® TURBO with a self-adhesive polyester liner, enables a reposition.

The raw materials are ecologically inert, do not contain PVC, plasticizers or heavy metals (in accordance with OEKO-Tex® Standard 100 category 1).

For cotton & cotton / polyester mixtures:

- Mirror your image

- Cut

- Weed excess vinyl

- Preheat for 2 to 3 seconds

- Protect your design with parchment paper or teflon sheet

- Press at : - 265f / 130c - 5 seconds

-300f / 150c - 4 seconds

-320f / 160c - 3 seconds

- Press at medium pressure

- You can peel the carrier or transfer sheet hot or warm

- When using highly structured cotton or cotton mixture fabrics, adjust the application time.

For nylon:

- Preheat project for 5 seconds

- Press at Low pressure

- 300f / 150c - 5 seconds

- Remove transfer / carrier sheet , cover with parchment paper or teflon sheet and press for another 10 seconds.

| Fabric | Time | Temp | Pressure | Peel | Special Instructions |

|---|---|---|---|---|---|

| Cotton Cotton/Polyester (Mixture) |

3 sec. | 320° F | Medium | Warm | |

| 4 sec. | 300° F | ||||

| 5 sec. | 265° F | ||||

| Polyester/Acrylic (Mixture) |

5 sec. | 300° F | Low | Warm | |

| Nylon | Pre-Heat 5 sec. Apply Nylon 5 sec. |

300° F | Low | Warm | Remove PET liner, cover transfer with silicon paper and apply for further 10 sec. |

** Please consider to adjust the application time when using highly structured cotton or cotton mixture fabrics