Features And Highlights

- Precise, repeatable registration from screen-to-screen

- Simple to set up and use, with sizes to fit most textile screen frames

- Double Tri-Loc allows two synchronized screens to be exposed simultaneously

Additional Information

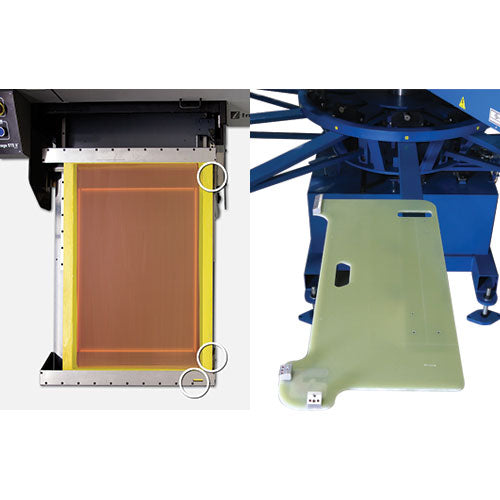

- MASTER EXPOSURE REGISTRATION FRAMES

-

- Double Tri-Loc: Non-adjustable

- Tri-Loc: Adjustable or non-adjustable

- REGISTRATION PALLET

-

- On-press registration pallets are available in a variety of sizes

- STARTUP KIT

-

- Contains two pin bars and 100 pre-punched carrier sheets

- STOP BLOCKS

-

- For accurate positioning of Tri-Loc pallets

- TRI-SYNC REGISTRATION PALLET

-

- LEDs confirm proper screen placement prior to screen frame lockdown

- VIDEO TRAINING

-

- Instructional video covers procedures for exposure and screen setup, and includes a tips & troubleshooting section

- CUSTOM SIZES

-

- Contact M&R for details

- PIN BARS

-

- Additional bars

- PRE-PUNCHED CARRIER SHEETS

-

- Available in various sizes

- REGISTRATION PALLET

-

- Aluminum registration pallet

- STOP BLOCKS

-

- Additional blocks for multiple press use

|

DIAMONDBACK C TRI-LOC |

TRI-LOC 20X24 NON-ADJUSTABLE MASTER FRAME |

TRI-LOC 23X31 NON-ADJUSTABLE MASTER FRAME |

TRI-LOC 23X33 NON-ADJUSTABLE MASTER FRAME |

TRI-LOC 25X33 NON-ADJUSTABLE MASTER FRAME |

TRI-LOC 25X36 NON-ADJUSTABLE MASTER FRAME |

TRI-LOC 25X33-36 SEMI-ADJUSTABLE MASTER FRAME (LENGTH ONLY) |

TRI-LOC 23-25X31-36 ADJUSTABLE MASTER FRAME (WIDTH & LENGTH) |

|

| Footprint | 65 x 83 cm (25.75" x 32.75") | 62.87 x 73.03 cm (24.75” x 28.75”) | 71.12 x 91.44 cm (28” x 36”) | 71.12 x 96.52 cm (28” x 38”) | 76.20 x 96.52 cm (30” x 38”) | 76.20 x 104.14 cm (30” x 41”) | 76.20 x 121.29 cm (30” x 47.75”) | 90.81 x 126.37 cm (35.75” x 49.75”) |

| Part Number | EXREG-21x28 | EXREG-20X24 | EXREG-23X31 | EXREG-23X33 | EXREG-25X33 | EXREG-25X36 | ADJEXREG 25X33-36 | ADJEXREG 23-25X31-36 |

| Screen Frame Size | 53 x 71 cm (21" x 28") | 50.80 X 61.96 cm (20” x 24”) | 58.42 x 78.74 cm (23” x 31”) | 58.42 x 83.82 cm (23” x 33”) | 63.50 x 83.82 cm (25” x 33”) | 63.50 x 91.44 cm (25” x 36”) | 63.50 x 83.82 cm (25” x 33”) - 63.50 x 91.44 cm (25” x 36”) | 58.42 x 78.74 cm (23” x 31”) - 63.50 x 91.44 cm (25” x 36”) |

|

DOUBLE TRI-LOC 23X31 NON-ADJUSTABLE MASTER FRAME |

DOUBLE TRI-LOC 23X33 NON-ADJUSTABLE MASTER FRAME |

DOUBLE TRI-LOC 25X33 NON-ADJUSTABLE MASTER FRAME |

DOUBLE TRI-LOC 25X36 NON-ADJUSTABLE MASTER FRAME |

|

| Footprint | 92.71 x 143.51 cm (36.5" x 56.5") | 97.79 x 143.51 cm (38.5" x 56.5") | 97.79 x 153.67 cm (38.5" x 60.5") | 105.41 x 153.67 cm (41.5" x 60.5") |

| Part Number | EXREG-23X31 | EXREG-23x33 | EXREG-25X33 | EXREG-25x36 |

| Screen Frame Size | 58.42 x 78.74 cm (23” x 31”) | 58.42 x 83.82 cm (23” x 33”) | 97.79 x 153.67 cm (38.5" x 60.5") | 105.41 x 153.67 cm (41.5" x 60.5") |

Is the TRILOC Registration System (For Film-Based Screen Production) right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the TRILOC Registration System (For Film-Based Screen Production) to your apparel decorating business.