Features And Highlights

- Simple to learn, setup and use, with sizes to fit the industry-standard screen frame dimensions

- Huge savings in setup times on multi-color jobs

Additional Information

Registration Process For Film-based Screen Production

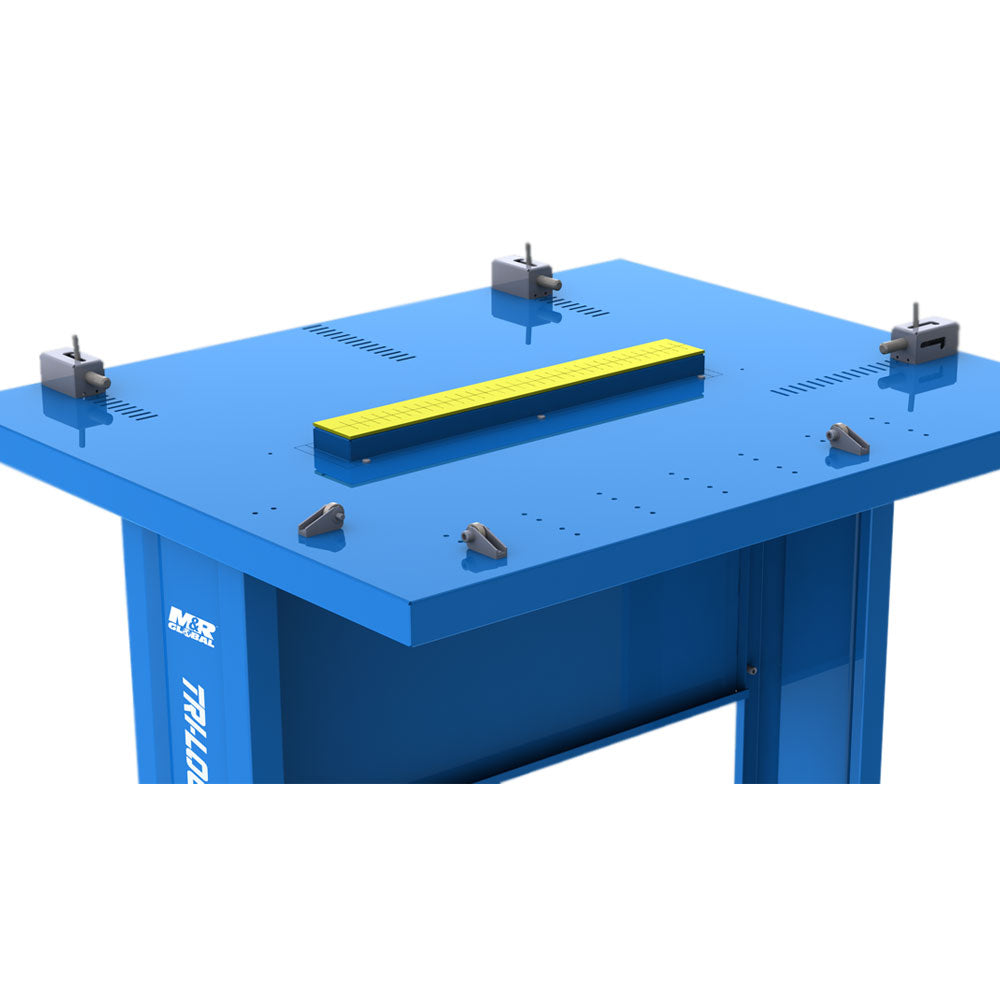

1. Place the screen on the Tri-Loc “I” Series registration system table. Lock the screen on all three sides.

2. Align positives in the same position on all screens and attach with clear tape. Expose, rinse and dry each screen.

3. Remove the printing pallet and load the Tri-Loc “I” Series pallet. Load the first screen in the design and lock after positioning in the Tri-Loc “I” pallet.

4. Align all screens in the proper printing order using the same method and locking them in position using the Tri-Loc “I” pallet. Replace the Tri-Loc “I” pallet with the printing pallet.

- Minimizes the required skills of a traditional artist who needs to cut, position, and align films.

- The accurate three-point contacts are built using CNC machines to insure precision placement and screen frame alignment consistency.

- The three point contacts of the registration table and pallet jig are mounted with smooth roller bearings to minimize scratches on aluminum screen frames and reduce the chances of registration errors.

- The guide that is mounted on the UV safe lightbox aids in alignment of films while avoiding screen pre-exposure.

- Spring-loaded clamps firmly hold the screens while aligning positives.

- The screen clamps are adjustable to fit various screen sizes.

- The registration pallet is fabricated from a single metal sheet to aid in alignment consistency and sit firmly on the pallet arm attachment.

- The design of the contacts on the pallet avoid scratches on the screen frame while the print heads move up and down.

- The pallet includes quick release locking pins to easily switch back to the printing pallet.

Is the COPPERHEAD TRILOC I SERIES Registration System (For Film-Based Screen Production) right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the COPPERHEAD TRILOC I SERIES Registration System (For Film-Based Screen Production) to your apparel decorating business.