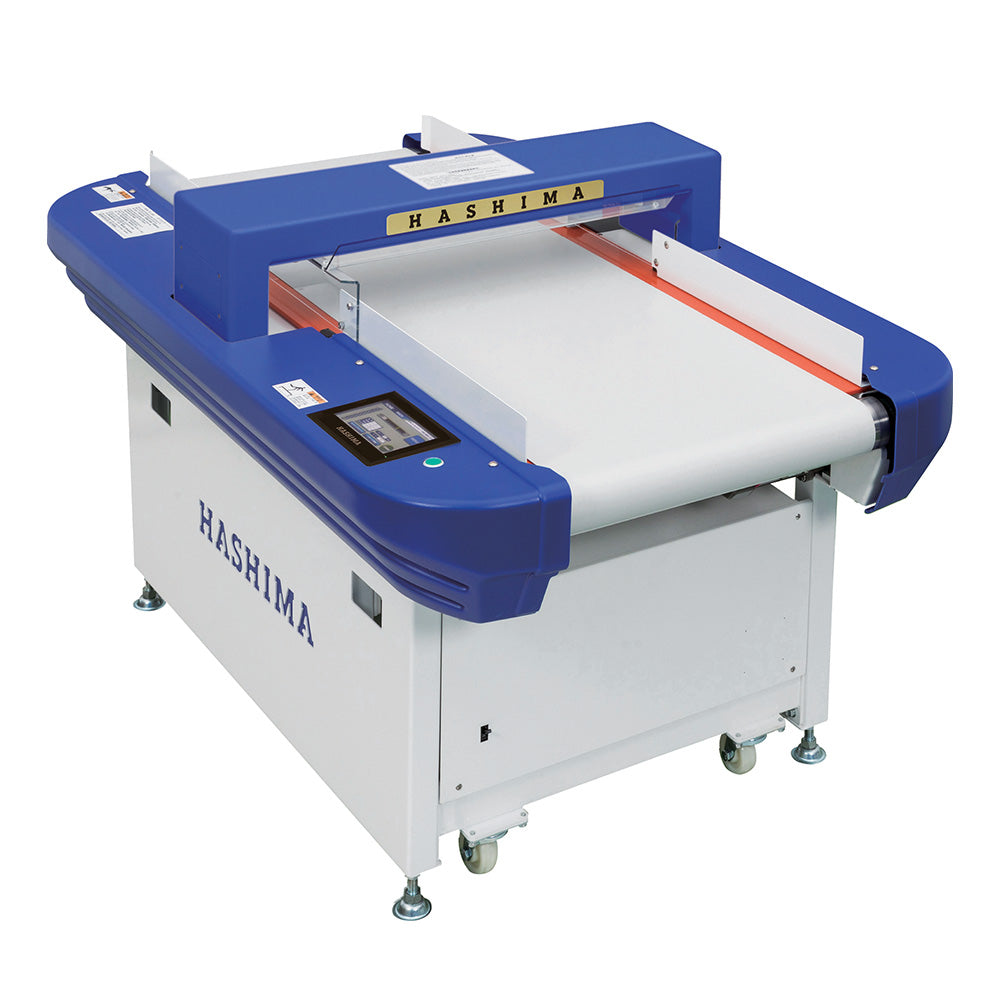

The Hashima Conveyor Type Needle Detector detects iron pieces such as broken needles that are not visible to the human eye, stuck on your apparel after sewing. Pass through your garment through the conveyor belt to identify that a needle is in fact stuck on the fabric. Then use a Handy Type Needle Detector to easily identify the exact position of the needle.

Adoption of new type of sensor

The development of a new type of serch coil and optimization of the magnet arrangement relationship have greatly improved the foreign object detection capability compared to the conventional machine. The detection height is 120 mm high, enabling detection of ferrous ball φ0.8 mm.

Equal sensitivity range expansion

Sensitivity irregularities in the detection mouth have been greatly reduced. Reducing material effects has greatly improved the pass ability of products.

Auto PreChecker (Automatic pre-check inspection function)

Auto PreChecker makes sensor checking more accurate and quicker. By using PreCheck Bar (Specialized test block) & system, you do not need to check each coil one by one, the system checks sensors automatically. Also you can keep the PreCheck result if you prepare the optional printer. ※Click here for an introduction to Aut PreChecker®.

7-inch large color LCD

A large 7-inch color LCD with PLC is used. It has excellent visibility and operability, and in addition to the conventional sensitivity settings, language setting, history information, etc., it is now possible to set an administrator password and export history via USB.

Sensitivity Level Monitor

Improved monitor level visibility. The position indicator lamps are divided into 8 sections to accurately indicate the position of foreign objects.

Super Fine Mode(Patent No.5199725、5324818)

Equipped with Super Fine Mode, which slows down the conveyor speed to improve the passage of accessories that are prone to false positive reactions. Accessories that do not cause false positives are inspected at 40 m/min, the fastest in the industry, for improved meter reading efficiency. Products that cause false positives can be adjusted between 40 and 15m/min increments of 1m/min.

Environmental mode

Self-determine if there is noise in the area where the needle detector is located that could cause the needle detector to malfunction. The auto pre-checker makes self-diagnosis of the needle detector itself, and the environmental moded makes it possible to self-diagnose the installation location.

Product Guider

The product guider, previously an Option product, is now standard equipment. The upper part of the sensor head, which often cause false detection due to product, is now covered, allowing safe inspection of thick products.