Often Purchased With

-

-

Brother GTX Pro B

gtxpro-b -

Brother GTX 600

GTX600

Additional Information

- Heat stabilized

- Little to no shrinkage

- Excellent printing outcome

- High matte quality

- Easy and smooth to peel

- Good scratch resistance

- Recommended cure times: 15 seconds at 158°C

- Treated to reduce the effects of static

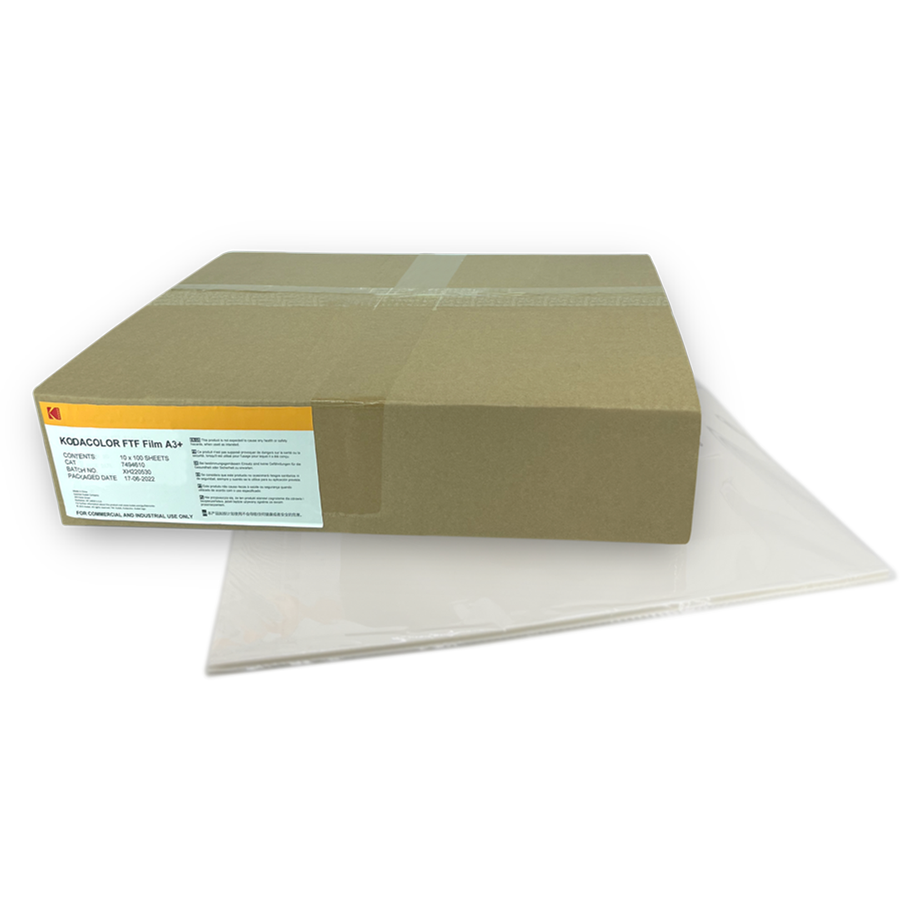

Step 1 – Printing on Film

- Using a DTF inkjet printer, insert Kodak DTF/FTF transfer film in printer paper tray or on paper roll holder

- For Dark shirts

- print color image on the film

- print white image layer on top of the color image

- For Light shirts:

- print color image on the film

Step 2 – Powder Application

- Apply the Kodak DTF/FTF hot-melt powder uniformly on top of the wet print

- White powder may be used for all applications or black powder may be chosen for dark work

- Powder may be sprinkled manually onto the print in a tray and agitated to cover print completely

- NOTE: an automated commercial shaker may also be used for powder application

- Ensure that the powder is evenly spread over the printed surface of the film

- Carefully remove excess powder

Step 3 – Melting the Powder

- Place the film with the printed image and the applied powder in a Curing Oven and heat for 2-3 minutes at 100-120oC

OR

- Place the film inside a heat press, hovering and not applying pressure. A 4 to 7 mm gap between the film and the heat press top plate is recommended, for 3-5 minutes at 140-150oC. Do not completely close the press.

Step 4 – Pre-pressing

- Pre-press the fabric prior to transfer of the image by the film for 2 to 5 seconds

- Pre-pressing will flatten the fabric and remove excess humidity contained in the fabric

- Pre-pressing helps in successful transfer of the image from the film onto the fabric

Step 5 – Transfer

- The film with the image and the melted powder is placed on the pre-pressed fabric in the heat press

- Press/Cure the image to the fabric for 10-20 seconds at 160-180oC

Step 6 – Cold Peel

- Allow the film/image attached to the fabric to cool completely

- Separate the film from the fabric, leaving the desired image on the fabric

Step 7 – Post-pressing

- A post-press process is highly recommended for best results and high-performance parameters such as wash and rub fastness

- Re-press the image on the fabric for 10-20 seconds at 160-180oC