Often Purchased With

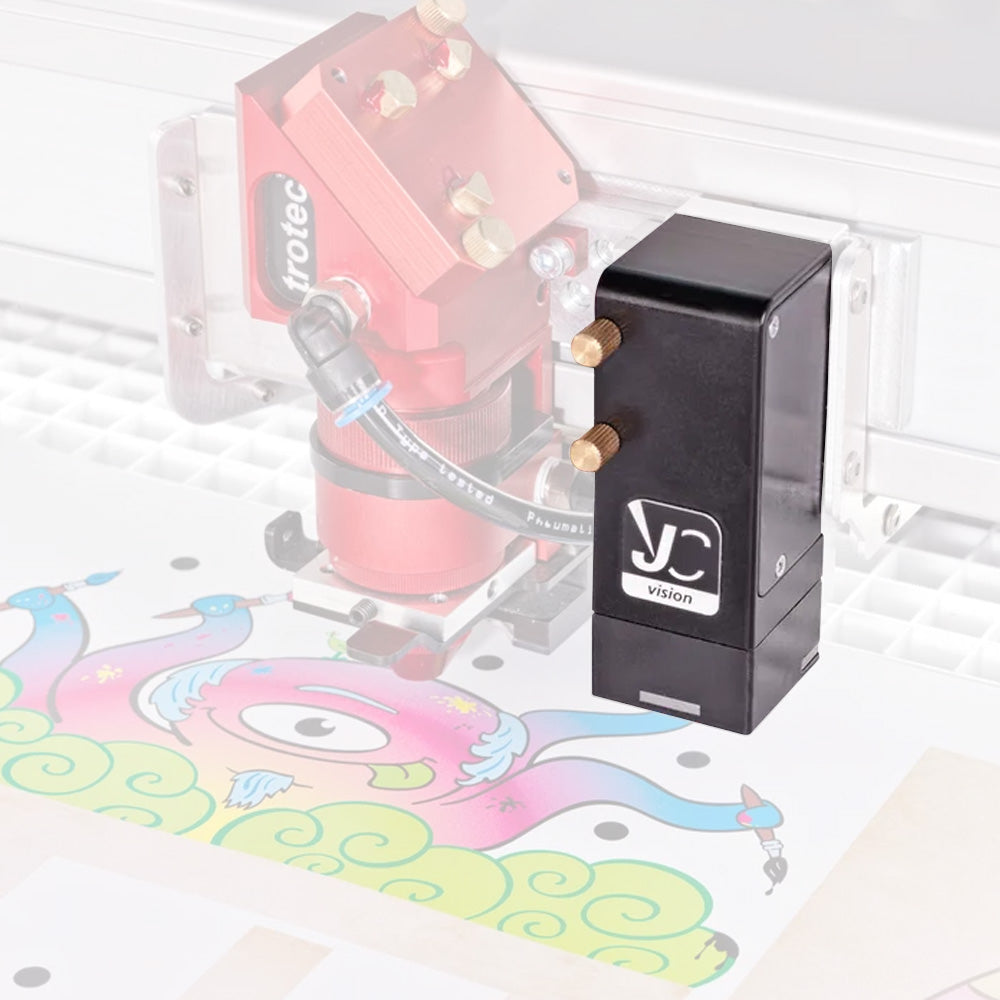

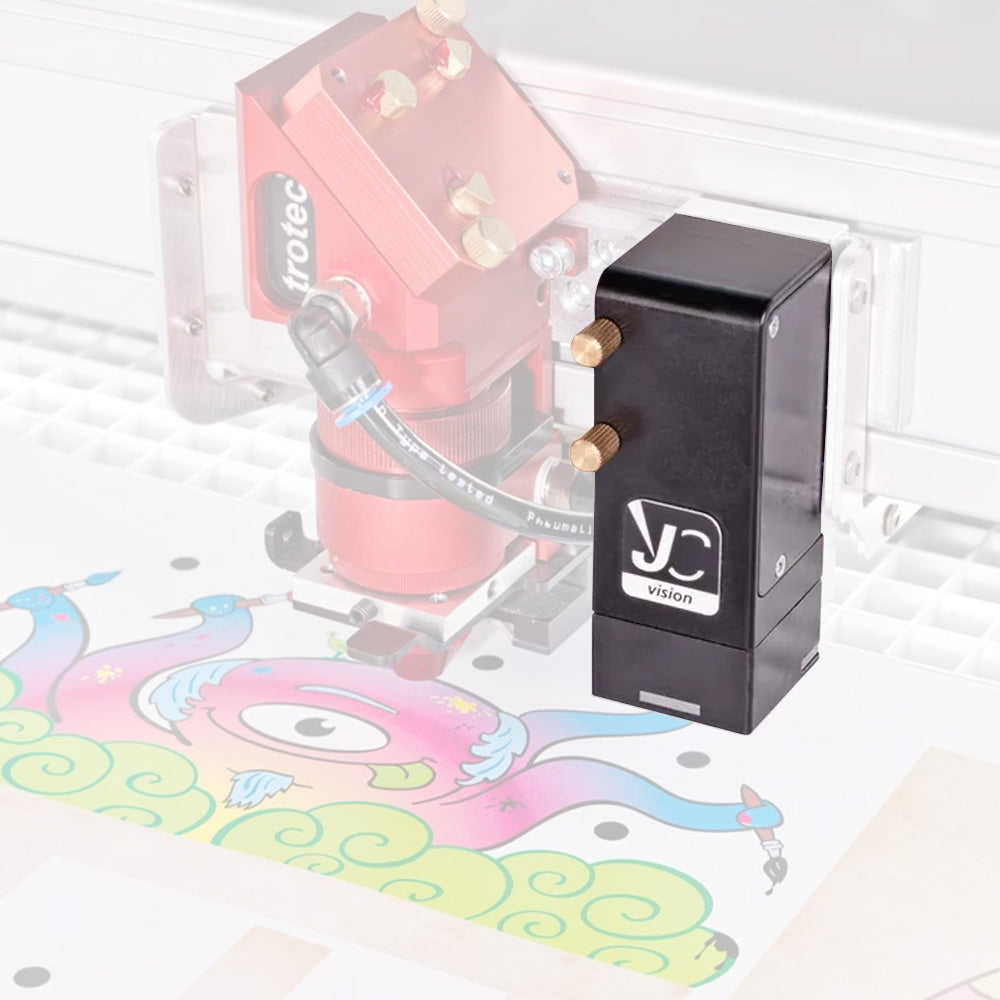

Trotec Job Control Vision

Laser Cutting Camera System

-

The Screen as a "Virtual Laser Machine"

Never strain or search for laser jobs in a tiny window ever again! JobControl® allows you to take full advantage of your big, bright computer monitor, enabling the user to move and position jobs freely from the job list to any position in the "virtual laser machine" and begin a job without leaving your chair or touching the machine. Productivity and practicality are our goals. -

-

Processing via Colour Mapping

Set processing settings such as engraving or cutting, speed, power level, number of passes, Z-offset, etc. by colors:

Automatic Z-Axis Control: Helpful for objects with different focal point positions.

Multiple engraving passes: Allows you to achieve the best possible engraving or cutting quality when dealing with delicate materials.

Webs: By interrupting the cutting line at defined intervals cut parts do not fall away from the raw material. This is very useful when producing entire stamp plates or filigree cutouts.

All settings are carried out in a single production step - No additional work steps are required! -

-

JobControl Vision: Software for precise laser finishing of printed materials

The software uses registration marks to determine the position and rotation of printed material on the laser’s work area. In addition, all distortions – linear and non-linear – are detected by the intelligent JobControl® Vision camera in the printed area. -

-

Job Control Cut Get a Perfect Cutting Result in a Few Easy Steps

With JobControl® Cut, Trotec offers laser cutting software for high-quality and efficient laser cutting. CAM functionalities such as kerf correction, lead-in flags, path optimization or node processing enable precise and productive laser cutting. Directly integrated into JobControl®.

Additional Information

Highlights of JobControl® at a Glance

-

Efficient Job Management

-

All jobs sent to the laser are stored in a clear list (filter by name, date, process type, resolution, etc.)

-

Jobs can be repeated at any time with one click

-

Job favorites let you save laser settings (size, resolution, material, cut lines, etc.) for recurring work

-

Place jobs from the queue on the work surface multiple times, duplicate and rotate easily

-

-

Precise Positioning Aids

-

Guides: Position jobs exactly where material is on the table to save waste

-

Marker: Magnetic positioning aids allow quick template creation for recurring jobs

-

-

WYSIWYG (What You See Is What You Get)

-

On-screen representation shows a true-to-original preview to reduce material waste

-

-

Photo-Optimized Engraving

-

Produces pin-sharp, detailed engraved images

-

-

Autofocus

-

Accurate focusing with one click

-

Saves material thickness, lens focal length, cutting table, and engraving parameters in the database

-

Software calculates the correct focal position automatically

-

-

Engraving Time Calculator

-

Displays estimated processing time in advance for accurate planning

-

-

MeshEngraving Technology

-

Patented feature for optimized engraving results at maximum speed

-

Reduces distortion for fiber laser applications

-

-

Maximum Engraving Resolution

-

Up to 2540 dpi resolution

-

Suitable for high-resolution screen printing plates, annealing marking of metal, or recoloring of aluminum with fiber lasers

-

Is the Trotec Job Control (Laser Software) right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Trotec Job Control (Laser Software) to your apparel decorating business.