APPLICATIONS OF HEATER WIRES

-

Heater wire sewing on heated clothing such as shoes, gloves, jackets, hats, etc. for protection against cold weather

Heater wire sewing on heated clothing such as shoes, gloves, jackets, hats, etc. for protection against cold weather -

Heater wire sewing for car seats and steering wheels

Heater wire sewing for car seats and steering wheels -

Heater wire sewing for outdoor snow melting carpet and bathroom insulation sheets

Heater wire sewing for outdoor snow melting carpet and bathroom insulation sheets -

Heater wire sewing for valve and plumbing covers

Heater wire sewing for valve and plumbing covers -

Heater wire sewing for electric blankets, heated carpets, heated mattress covers, and thermal insulators

Heater wire sewing for electric blankets, heated carpets, heated mattress covers, and thermal insulators -

Flexible heaters used in chemical process applications and heated pipe covers for freeze protection

Flexible heaters used in chemical process applications and heated pipe covers for freeze protection

KEY FEATURES

-

Mass Production by Use of the Multi-Heads

The largest Heater Wire Sewing Machine with 16 heads, can produce 16 pieces at a time. This greatly improves productivity and reduces cost per part. -

A Simple Operating Process

The process is automated and simplied. Many options are available to increase production and create accurate wire parts. The Heater Wire Sewing Machine makes production a smoother process especially when compared to the conventional way that wire-laying is done. -

An Easily Reproducible Process

A computer-controlled head and frame sews heater wire automatically and precisely. The pitch between stitched wires can be accurately controlled for various wire diameters. Other conventional methods of production make it difficult to accurately reproduce corners as designed. Our new technology has now made it possible to produce corners that are consistent in length and resistance. -

Digitizing Is Simple

Our exclusive digitizing software named “DG/ML by PULSE” is designed to support your pattern requirements. “DG/ML by PULSE” makes it easy to edit and simply convert existing data and designs to stitch data files ready to run on the Heater Wire Sewing Machines.

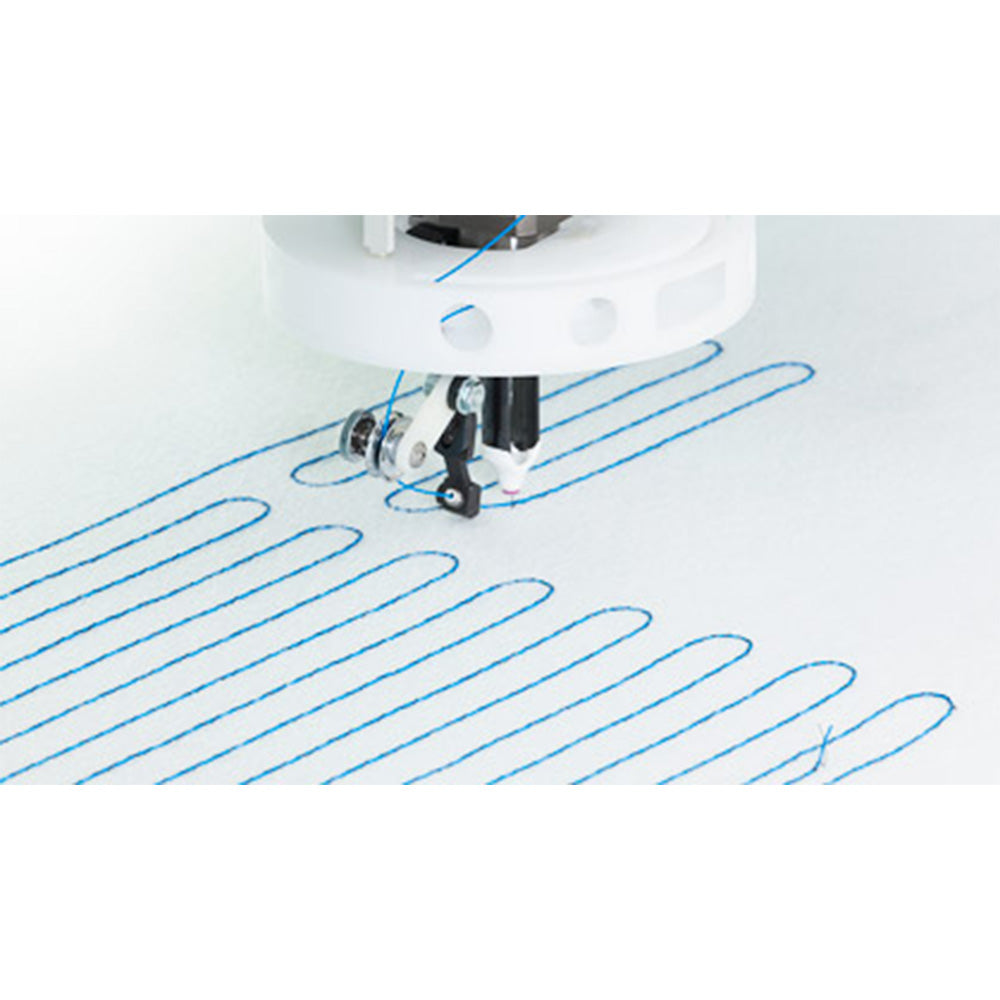

ZIG-ZAG SWING

In some conventional methods of production, the heater wire is attached using an adhesive then sandwiched and pressurized. This process may cause wire breaks. With the Heater Wire Sewing Machine, the conventional wire-laying problems are eliminated. The wire is stitched with a zigzag pattern to allow for expansion and contraction during pressurization and operation. This result in a much more durable and reliable product.

There are 6 different zig-zag swing stitch patterns which enable the Heater Wire Sewing Machine to sew a wide variety of wire sizes and types precisely onto the substrate materials.

Additional Information

| Model | Needles | Lock-stitch Chenille Heads | Head Interval | Embroidery Space DxW (mm) |

| TLMX-101 | 1 | 1 | 800 | 800 x 800 |

| TLMX-111 | 1 | 10 | 600 | 1,200 x 600 |

| TLMX-T01 | 1 | 1 x 2 | 875 | 750 x 875 / 325 |

| TLMX-T08 | 1 | 8 x 2 | 750 | 1,200 x 750 / 195 |

Is the Tajima TLMX (Heater Wire Sewing Machine) right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Tajima TLMX (Heater Wire Sewing Machine) to your apparel decorating business.