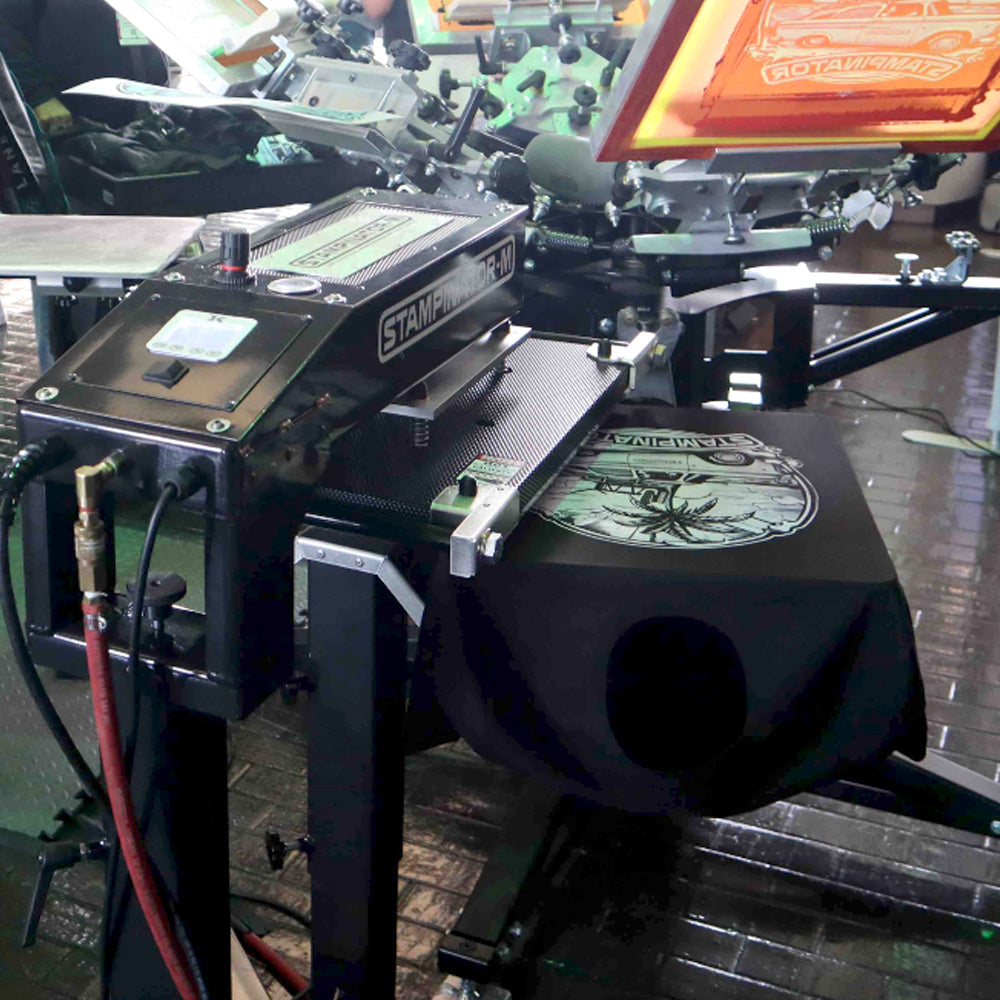

See It In Action

Proven Methods for Using the Stampinator on Manual Screen Printing Presses

3 In 1 Stamp Flash: Replacing a standard quarts or IR flash with the Stampinator simultaneously

-

Creates the Ultimate Print SurfaceUse the Stampinator in head one to pre heat press any garment, smoothing fibers, removing lint, and warming the print surface.

-

Mattes Down Fibers

Builds the ultimate underbase and reduces the ink deposit needed as the Stampinator mattes down fibers. -

Flash in 2-3 Seconds

At a controlled temperature, the Stampinator flashes garments in 2-3 seconds. -

Save Press Space

Replaces the need for a roller head and maintaining a consistent platen temperature without overheating. -

Replaces Conveyor DryerUse the Stampinator in the last head to on contact cure on press without the need of a conveyor dryer and load directly onto a staging cart.

Accessories

What if You Could Press Transfers as Fast as Your Press Could Print?

With the Patented technology of the Stampinator, you can turn any automatic screen printing press into the fastest heat transfer machine you’ve ever seen.

-

Transform Your TransfersConvert any automatic press into the ultimate transfer machine capable of producing over 480 transfers per hour.

-

Increase ProductivityWith the rise of quality and versatility for specialty print placements and print on demand transfers and DTF, the Stampinator increases your shops productivity by over 400%.

-

Save SpaceNow you can use the space you were using for your old heat press for something else.

Learn More About The Stampinator On The InkPod Podcast

Additional Information

- Stampinator for Manual Presses

- Extra Teflon Sheet

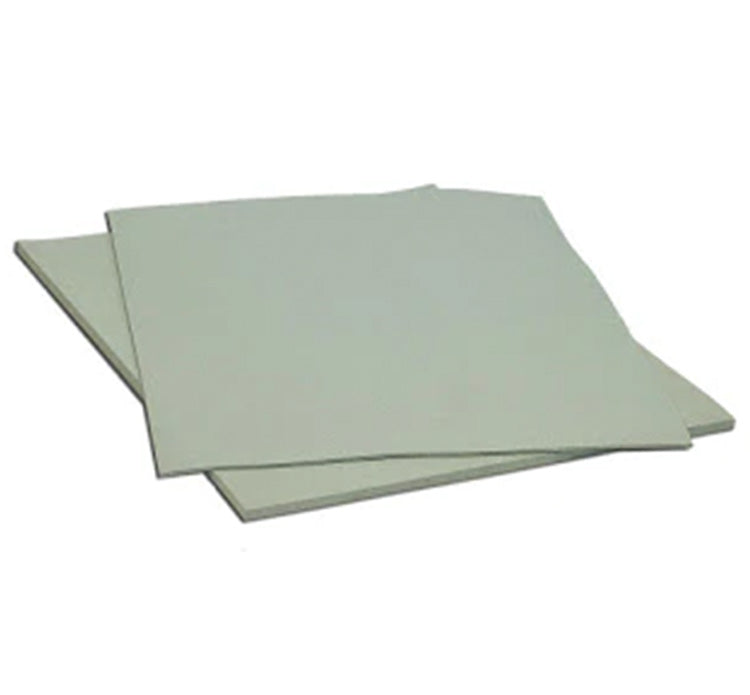

- Heat Conductive Green Rubber Insert

- 12' Pigtail Power Cord for wiring in a plug

The Stampinator fits:

- Anatol (All Manual Presses)

- M&R (All Manual Presses)

- Riley Hopkins (All Manual Presses)

- Workhorse (All Manual Presses)

- Weight: 250 lbs

- Electrical: 3600W / 16AMPS / 220V / 1 Phase

- Shipping Dimensions: W 48" x L 48" x H 48"

- Platen: 16" x 20"

- 2 Year Warranty on heat platen, full one year warranty on machine

- Fully digital temperature control 32° - 600°

- US Patent Pending

Heat Conductive Rubber is a unique closed cell silicone sponge that has very fine ceramic particles mixed in the polymer to enhance its thermal properties. This expanded, conductive rubber helps distribute pressure and protect delicate materials in the heat press. The rubber mounts between the teflon and the platen.

Adding the Green Rubber allows you to print and stamp over the seams. You can now matte fibers and cure the UB printing on almost anything with a seam such as V-necks, Tank Tops, Ladies and Youth Tees on large pallets.

Our Teflon is a 10mil allowing for the perfect cushion for every print. The 26" long Teflon Sheet mounts on the tensioner under the Stampinator 480. The tensioner allows for a tight fit laying flush to the platen. The sheet is 16" x 26"

Is the Stampinator Dryer and Inline Heat Press For Manual Screen Printing Presses right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Stampinator Dryer and Inline Heat Press For Manual Screen Printing Presses to your apparel decorating business.