Often Purchased With

-

Ergo-Force Squeegee Handle & Blade

EFSH4Regular price From $18.00 CADRegular priceUnit price per -

Ultimate Table-Top Squeegee-Rack

TTSRRegular price $65.00 CADRegular priceUnit price per -

Squeegee Clean - Main Box

SQCLNBOXRegular price From $1,250.00 CADRegular priceUnit price per -

Standard Squeegee Cleaner

CL10Regular price From $21.00 CADRegular priceUnit price per -

Double Squeegee Cleaner

DSSQCLRegular price $42.00 CADRegular priceUnit price per -

Squeegee & Flood Bar Recirculation Washer

RBE-32WRegular price $2,995.00 CADRegular priceUnit price per -

Diamond-Fine Squeegee Polisher

DFP-01Regular price $565.00 CADRegular priceUnit price per -

Diamond Short Cut Squeegee Sharpener

DSC-020Regular price $2,995.00 CADRegular priceUnit price per -

Squeegee Clipper (Rounds Squeegee Corners)

SQ-01Regular price $370.00 CADRegular priceUnit price per -

Squeegee Cutter

SQ-03Regular price $370.00 CADRegular priceUnit price per

Additional Information

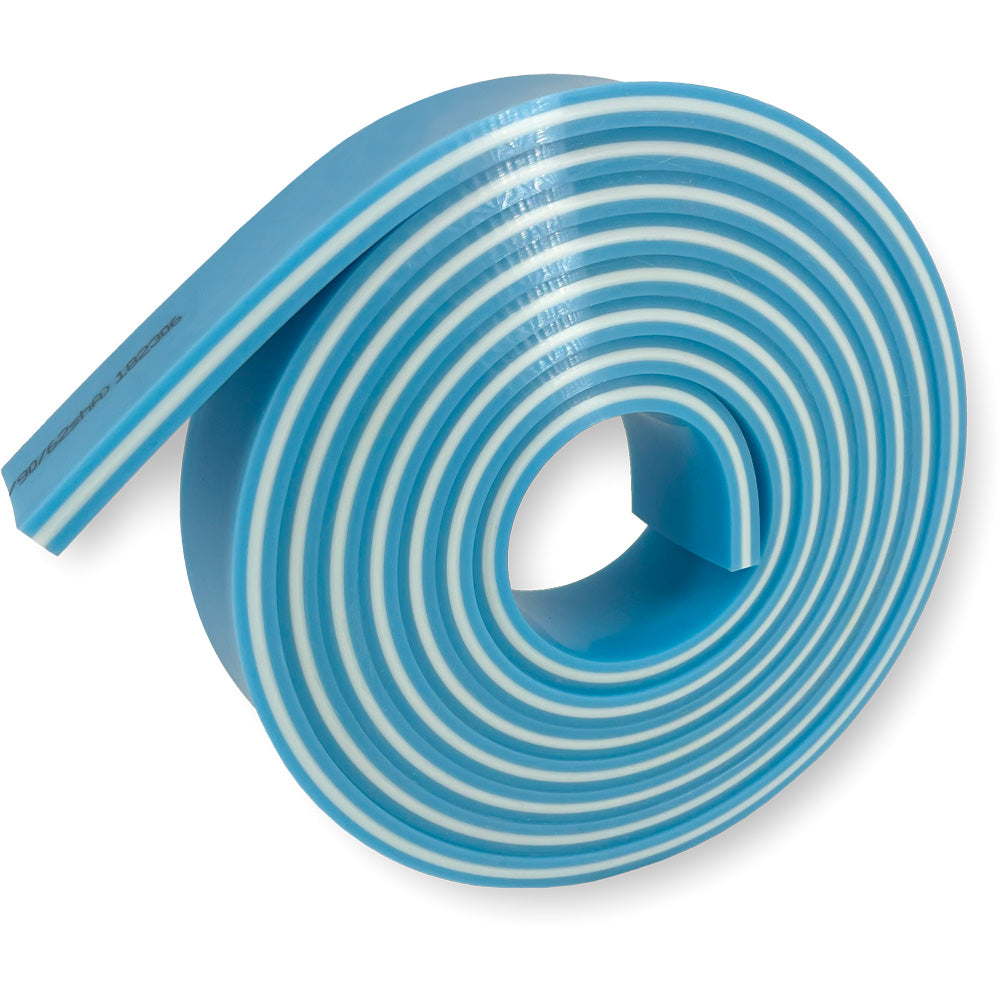

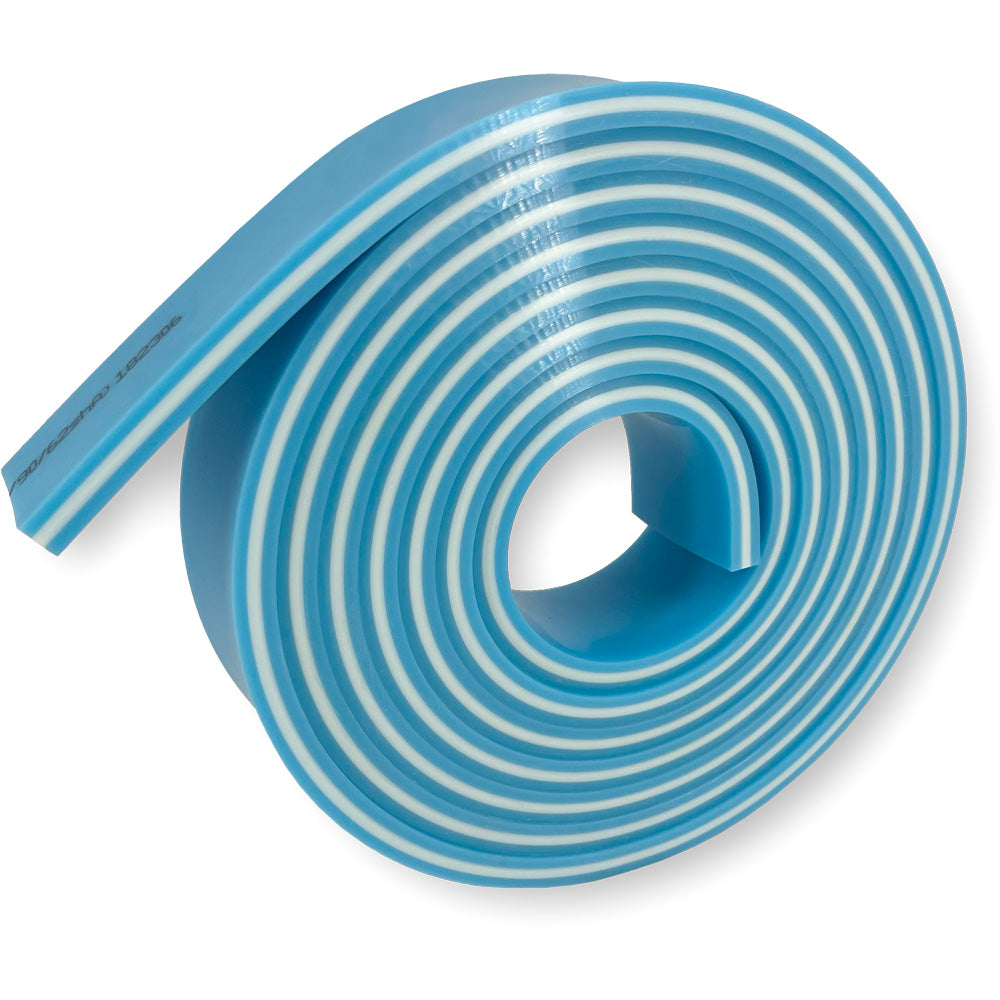

What is durometer? Durometer measures the hardness of the squeegee blade. Some squeegees are harder where as some feel softer. Specific print jobs require harder or softer blades. The durometer or hardness level directly indicates how thick or thin an ink deposit can be. Softer squeegees will leave a thicker ink deposit, while harder squeegees will leave a thinner deposit of ink.

- 80 durometer is hard and leaves a minimal ink deposit. Its best for designs going through higher mesh counts with lots of complex details or fine halftones where a thin ink deposit is needed for design clarity.

- 70 durometer is by far the most popular and versatile in the garment industry. It’s a great, general purpose blade for everything from spot colors to halftones. Majority of printers use the 70 durometer as their first squeegee blade.

- 60 durometer is one of the softest blades available. It allows for a thicker ink deposit through lower mesh counts. The durometer is ideal for special effects like puff, glitters, shimmers, and high density applications.

- 60/90/60 triple durometer gives you the benefits of the 60 durometer blade edge, allowing for a good deposit of ink. With the 90 durometer spine, it allows for greater pressure to be applied during printing with minimal squeegee blade deflection. This squeegee blade allows for more ink to be laid down compared to an 80 duro blade.

- 70/90/70 triple durometer gives you the benefits of the 70 durometer blade edge, allowing for a good deposit of ink. With the 90 durometer spine, it allows for greater pressure to be applied during printing with minimal squeegee blade deflection. This squeegee blade allows for more ink to be laid down compared to an 80 duro blade.

In general softer grades (65sh) are used for increased ink deposits and high coverage printing. Harder grades (85sh) are used for reduced deposits, notably when printing UV inks for fine texts and higher line counts. Do not apply excessive pressure on squeegees as this makes your ink deposit heavy, uncontrollable and creates excessive wear. It is recommended that your squeegee slightly exceeds the printed image in size. Make certain to leave significant free space between both ends of your squeegee and the inside of your frame.

Gently insert the squeegee in a machine or hand holder. Use appropriate squeegee thickness to avoid forcing the blade in the holder. If the holder construction allows for it, regularly change the printing side of the squeegee to minimise the effect of bending with speed and pressure. Rotate your squeegee: do not wait until mechanical & chemical wear permanently bends back your blade to replace it by a fresh one and allowing it to relax, flat, for up to 24 hours.

• CLEANING

Remove excess of ink with a cardboard or a soft cloth. Wash blade with a cloth saturated with appropriate cleaning chemicals. Avoid the use of aggressive chemicals, in particular ink thinners. Let the squeegee rest and the chemicals evaporate before re-use or sharpening.

• SHARPENING

serilor®LC squeegee blades can be sharpened by all methods commonly used in the screen printing industry (Fimor offers an extensive range of diamond wheel sharpeners, please contact us for more information). - Belt grinders - Wheel sharpeners - Knife cutting machines Sharpen dry squeegees only. Never allow a squeegee with solvents to be sharpened and don’t wash a hot, freshly sharpened blade with chemicals. Do not try to grind excessive material in one pass. Precision printing requires a preventive sharpening to accomodate the squeegee edge to the holder shape.

• STORING / SHELF LIFE

For all medium or long term storage, blades must be kept flat, unrolled, especially prior to use. Store in a dry cool place away from any direct source of light. If the squeegee is exposed to extreme temperature and humidity conditions, its hardness characteristics may be altered.