-

Precision in Embroidery

The high-precision camera system can automatically recognize the blank embroidery position regardless of where and at what angle it‘s placed on the platen. -

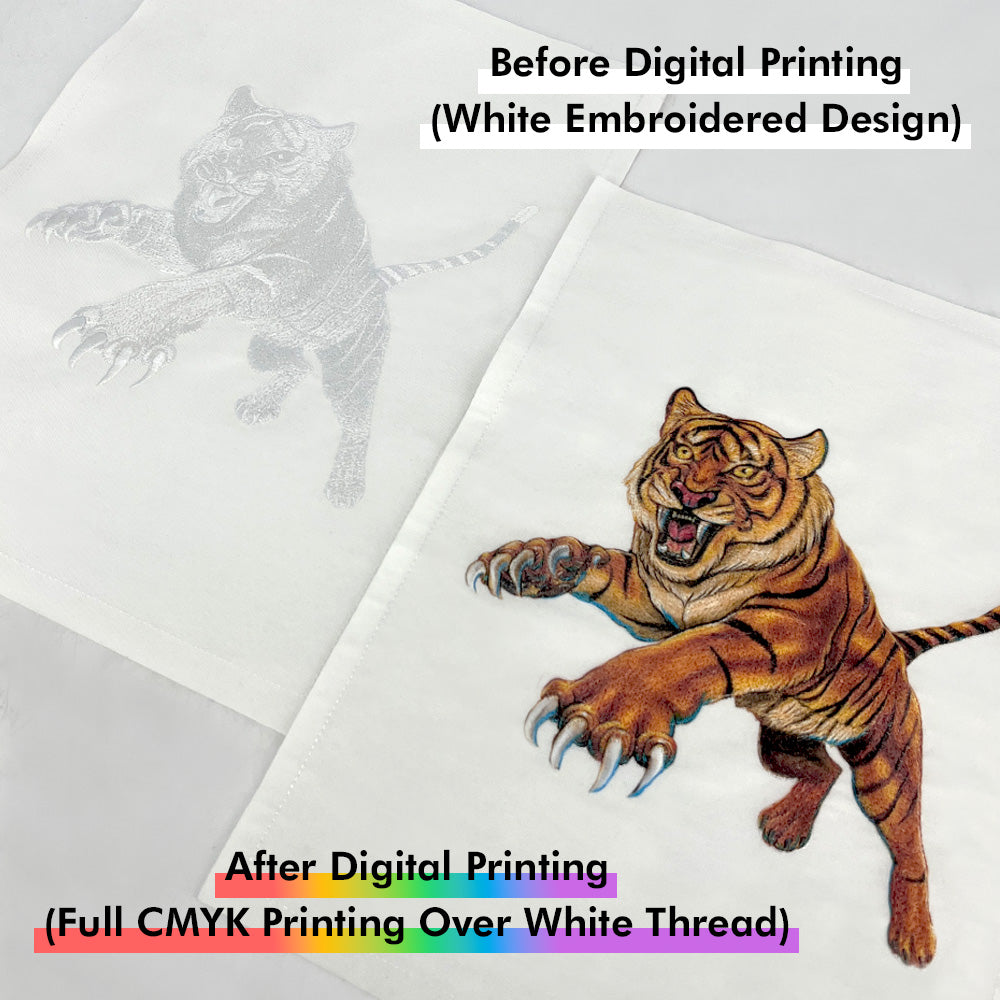

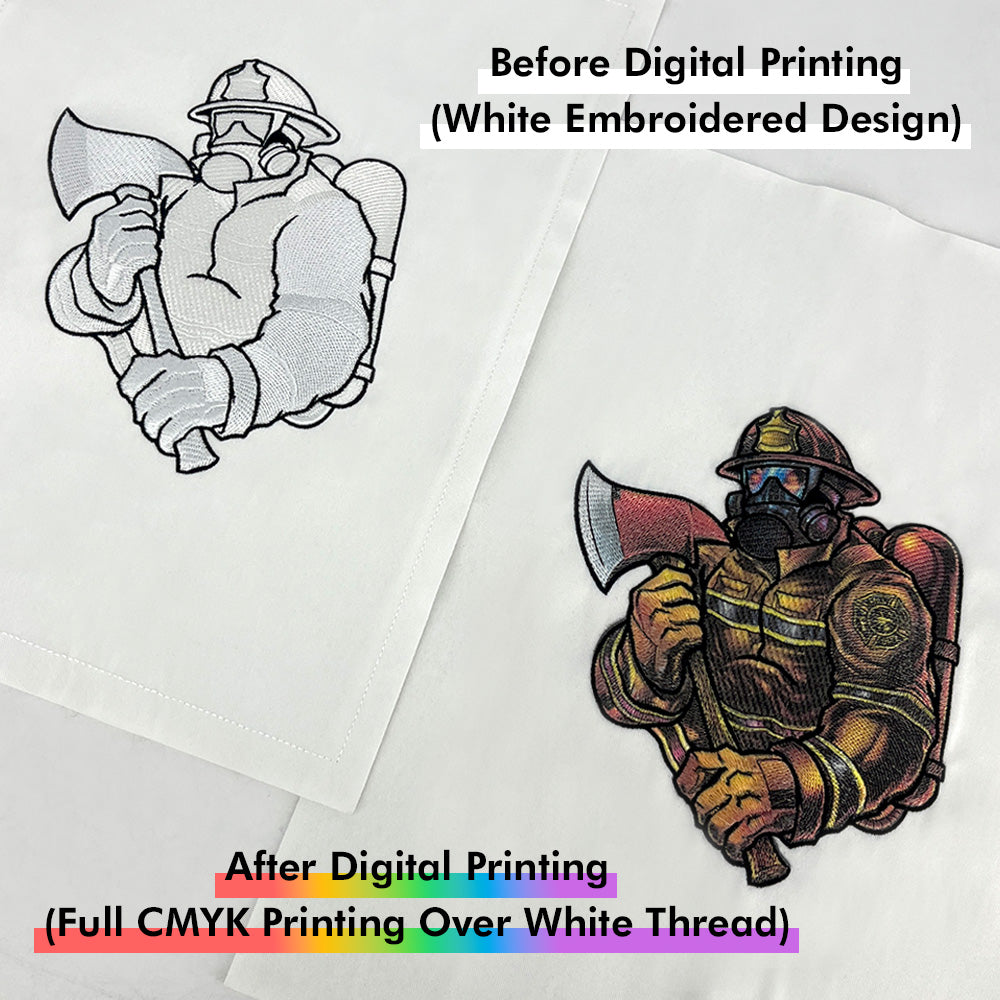

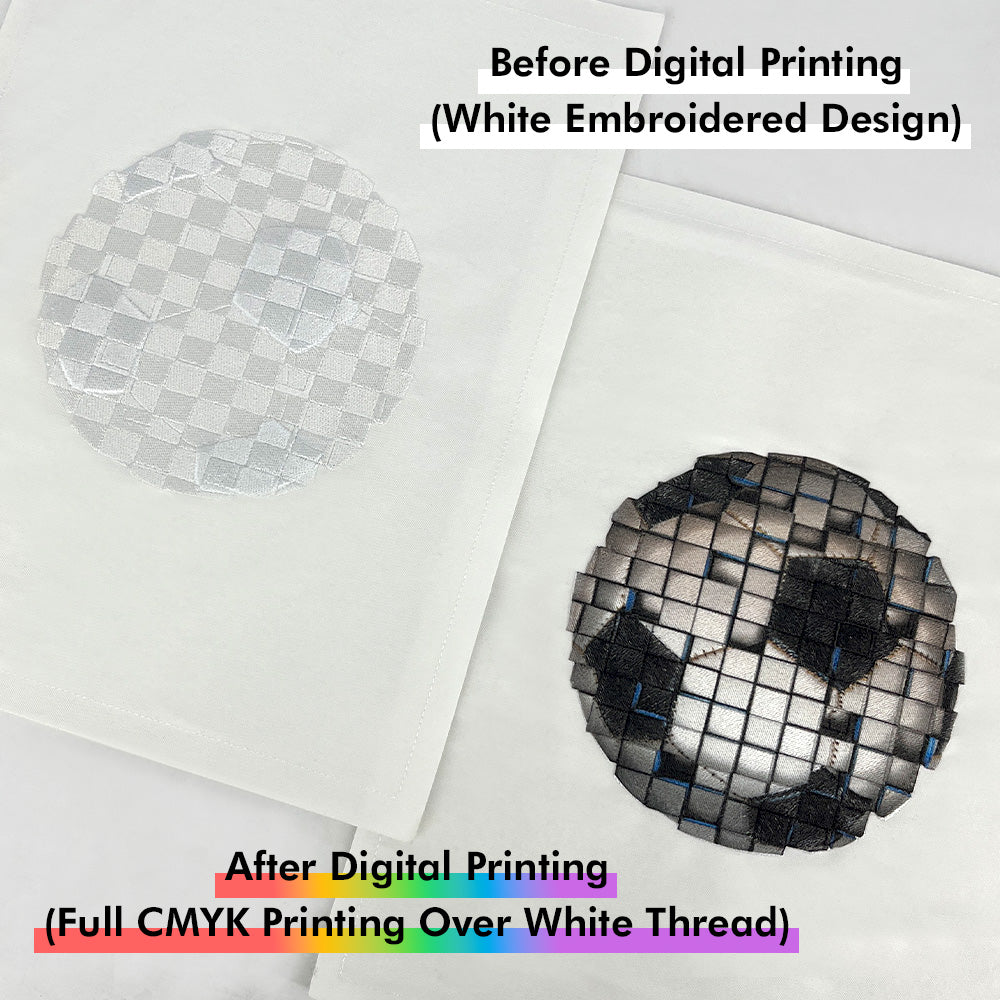

All Colour Combinations With White Thread

This innovative technology revolutionises finishing as all colours can be printed on white yarn. Therefore, no large stocks of different colours are required any more. -

Innovation for Traditional Embroidery

This solution allows traditional embroidery to have greater variation in expression, such as gradient colours and small characters.

How It Works

-

-

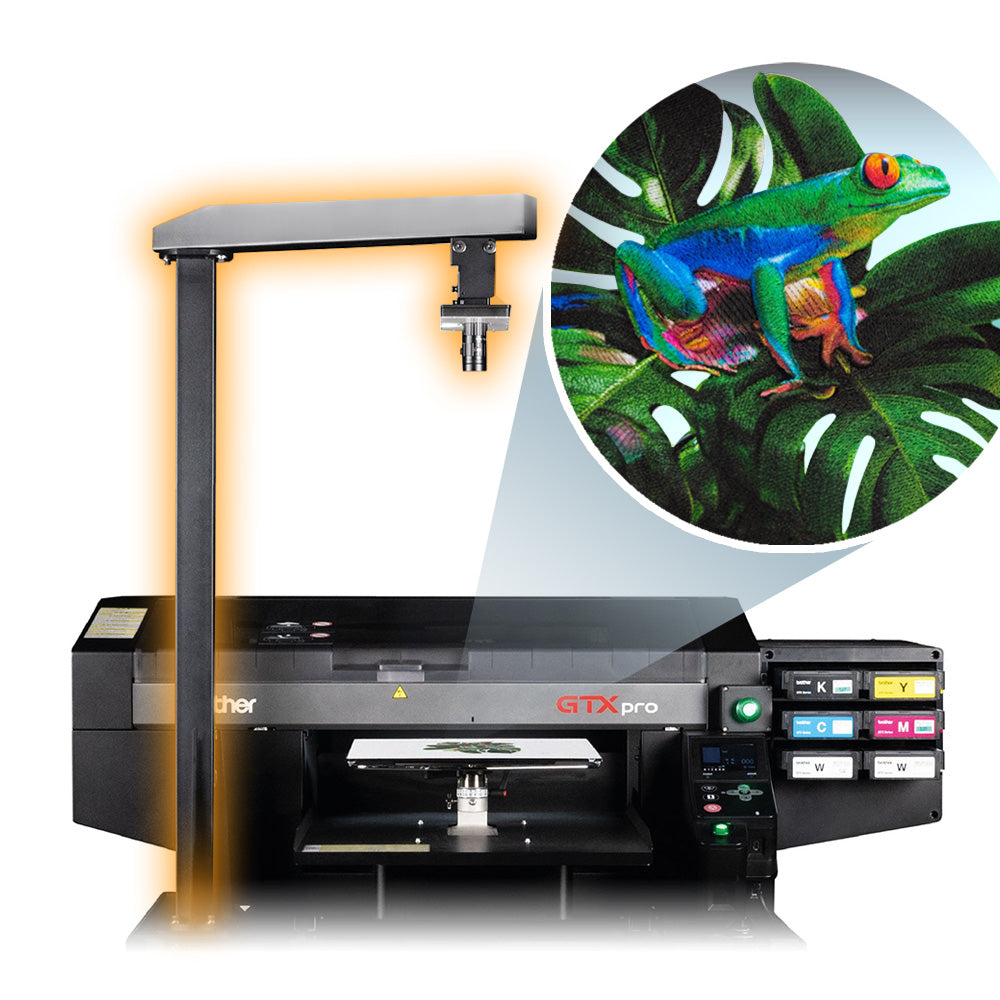

Ultra-High Resolution Camera System

The high-precision camera system automatically scans and recognised the embroidery on the garment, regardless of the placement or angle on the platen. Your artwork is then re-positioned perfectly and ripped automatically. All that’s left to do is to push the green button and watch the magic happen…

Bring Embroidery into the Digital Age

Integrating seamlessly with your existing GTX series printer, your full colour design is then printed directly on top of the embroidery with 1200dpi accuracy. Every detail realised, every edge pin sharp, watch your embroidery come to life. You even have the option to combine embroidery and print in one go and DTG onto surrounding areas of the garment in the same pass…

-

Revolutionize Your Embroidery Business

By utilizing a single color thread for direct to embroidery, the digitizing process is streamlined, requiring only one color digitization. This not only simplifies production but also increases efficiency, significantly reducing substantial stock costs of embroidery thread, thus promoting environmental sustainability. -

Additional Information

-

Step 1

Stitch the embroidery design in white thread on your desired garment using any embroidery machine. Preatreat the fabric to prepare for printing. -

Step 2

The DTE software is easy to use and only requires a simple calibration before printing. Using your embroidery design file, create templates within the software and select from preset print settings before you begin printing. -

Step 3

Load the garment onto the platen to begin printing. The camera automatically recognizes the embroidery design and aligns the artwork design for accurate printing. -

Step 4

Remove the printed garment and cure the print using a conveyor dryer.

ELECTRICAL SPECIFICATION PARAMETERS |

|||

| Input Voltage | 100 V - 240VAC, 50/60Hz, 1.4A | ||

| Working Voltage | Operating voltage DC 24V | ||

| Working Current | ≤1A | ||

| Rated Power | 24W, Max power while normal working | ||

| Working Temperature | -10 ~ 50°C | ||

CAMERA SYSTEM SPECIFICATION PARAMETERS |

|||

| Camera | 20 million pixels, camera (3.0 USB port) | ||

| Lens | 16mm high definition optical lens | ||

| Field of view | 16*14 inches | ||

COMPUTER CONFIGURATION INTRODUCTION |

|||

| Supported Computer Operation System | Win10/11, 64 BIT/win 10 64 BIT | ||

| Computer HDD Configuration | • CPU: Core(TM) i7-12 or above • RAM: 16 GB • HDD: 512 GB or above Screen Resolution: recommend 1920*1080 or above • USB3.0 port: one (connect with camera) • USB2.0 port: four (light source, USB key etc.) |

||

SIZE & WEIGHT SPECIFICATIONS |

|||

| Weight | 15KG | ||

| Bracket Size | 610mm*150mm*1120mm (Lenght*Width*Height) | ||

Is the Brother GTX Pro Direct to Embroidery (DTE) System right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Brother GTX Pro Direct to Embroidery (DTE) System to your apparel decorating business.