| OS | macOS® Big Sur to macOS® Monterey, Windows 8.1 (64-bit), Windows 10 (64-bit) and Windows 11 (64-bit) |

| Interface | USB2.0, LAN(10BASE-T, 100BASE-TX, 1000BASE-T), USB Flash Memory(Under 32GB, FAT32 format) |

Driver operating conditions |

2GHz CPU (minimum recommendation) 4GB RAM |

| Display resolution | XGA(1024x768) (minimum recommendation) |

| Recommended applications |

CorelDRAW® 2018/2019 (Windows), Adobe® Photoshop CS6/CC, Adobe® Illustrator CS6/CC |

MEET EVERY NEED OF YOUR CUSTOMER

Your range of applications is endless with the F Series. Enjoy industry-leading features and optional add-ons.

-

GoProduce software to perfectly match your F SeriesThe software GoProduce is developed to handle jobs easy and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible.

-

Multifunctional cutting head for cutting efficiencyThe multifunctional head can hold up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

-

Tangential Module for power and precisionOffering a vertical force of 10 kg and corresponding to a wide range of matching tools. Each tool has a barcode identifier, ensuring automatic recognition and parameter settings.

-

Advanced Safety SystemThe advanced Safety System, delivered with all F Series models, guarantees a safe work environment and is compliant to worldwide health and safety requirements. Thanks to the placement of the system on the top beam, the F Series can be accessed easily, which results in higher production efficiency.

-

Barcode for Automated workflowsThe barcode automatically identifies the job to obtain the necessary cutting data from the computer. The built-in camera scans the job automatically or by a hand scanner, depending on the selected workflow.

-

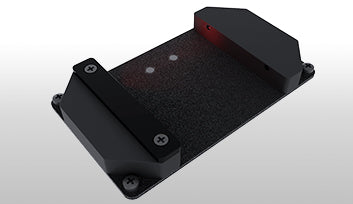

Automatic Depth Control (ADC)The ADC automatically sets the knife depth and the orientation of the tool. The tip of the knife or bit is measured accurately and the down position of the tool is set to table's level, guaranteeing a flawless cut. Both the ADC left and ADC right is included with every new F Series flatbed cutter.

-

Conveyor extension to minimize downtimeThe conveyor extension, optional on the F1612 flatbed cutter, processes cut designs that are much larger than the actual cutting area. While the machine cuts the next part, the first cutout parts can be removed safely at the extended front.

Note: image to be updated to F1612 with safety system.

-

Accelerated workflow with F-PerformanceIncrease the performance of your F Series flatbed system with almost 40%. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cutting tool.

-

Heavy-Duty Roll SupportThe optional Heavy-Duty Roll Support allows a straight throughput of print rolls onto the wide-format flatbed sizes, F1832, F3220 and F3232. For the processing of heavy banner material and light to non-stretchable wide textile rolls, this roll support will facilitate the operator’s life considerably.

CHOOSE YOUR SIZE OF VERSATILITY

Cutting tables are available in five models. Each of them is bound to significantly increase your productivity.

MEDIA HANDLING HAS NEVER BEEN EASIER

The extensive range of media handling solutions helps you to work precise and more efficiently.

- The advanced Safety System guarantees a safe work environment. Convenient placement on the top beam ensures easy accessibility of the flatbed to remove cut parts.

- Media Advance Clamps hold the material down while pulling it forward in order to work continuously in panels or multiple jobs.

- The vacuum pump with sound absorber holds the material in place during the job while the selector adjusts the vacuum automatically to match the working area.

- The Conveyor belt & Roll support allow the cutting and creasing of large lengths of flexible material to large production runs.

- The working area can be divided into two separate zones, a cut only zone and an Operator Zone where materials can be removed with ease.

- The optional Heavy-Duty Roll Support allows a straight throughput of heavy banner material, non-stretchable wide textile rolls and lightly stretchable materials onto the wide-format flatbed sizes F1832, F3220 and F3232. Video Heavy-Duty Roll Support

Additional Information

| Printing Method | Direct Inkjet Garment Printer |

| Machine Size | 1400mm x 1300mm x 550mm |

| Machine Weight | Approx. 120kg including Platen |

| Max. Printing Area | 16“ x 21“ (40,64cm x 53,54cm) |

| Plate Delivered | 14“ x 16“ (35,54cm x40,65cm) |

| Ink Type | Water-based pigment ink (200 and 500ml pouches available) |

| Ink Color | CMYKW |

| Ink-head type | Brother manufactured on demand piezo head |

| Number of ink-heads | 2 |

| Printhead resolution | 1200 dpi x 1200 dpi |

| Print Mode | Single or double for CMYK. Underbase and highlight for white |

| Enviroment | Operating conditions: 50°F(10°C)to 95°F(35°C) Humidity: 20-85% RH, Printing conditions: 64°F(18°C)to 86°F(30°C) Humidity: 35-85% RH |

| Data output | Printer driver (USB, File output, LAN) |

| Power supply | AC 100V-240V, 50/60Hz |

| Power consumption | 0.8A (average) (Reference: 0.4A (during circulation)) |

| Ink cure | Heat press machine can be used at 356°F (180°C) and 35 seconds duration. Conveyor oven is recommended to support high productivity of the printer at 320°F (160°C) and 3.5 minutes duration. Time and temp. may vary depending on which manufacturer‘s dryer is used. |

| Pre-treatment | Before printing, apply pre-treatment using either a manual or automatic device and then dry garment using a heat-press, being sure to follow all manufacturer‘s instructions. Pre-treatment is necessary for white ink. |

| OS | Windows 8.1 (64 bit), Windows 10 (64 bit), macOS 10.14 Mojave, macOS 10.15 Catalina |

| Interface | USB2.0, LAN (10 BASE-T, 100 BASE-TX, 1000 BASE-T), USB Flash Memory (Under 32GB, FAT32 format) |

| Driver operating conditions | 2GHz CPU, 4GB RAM |

| Display resolution | XGA (1024×768) |

| Recommended PC applications | CorelDRAW® X6/X7, Adobe® Photoshop CS6/CC, Adobe® Illustrator CS6/CC, CorelDRAW® 2018/2019 (Windows) |

Is the Summa Flatbed Cutter Series right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Summa Flatbed Cutter Series to your apparel decorating business.