Often Purchased With

-

Toyoda Falcon Commercial-Grade Industrial Humidifier

TF-HUMIDPrix habituel $600.00 CADPrix habituelPrix unitaire par -

Toyoda Falcon Industrial Portable Fume Extractor

TC-TOYODA-FEPrix habituel $2,800.00 CADPrix habituelPrix unitaire par

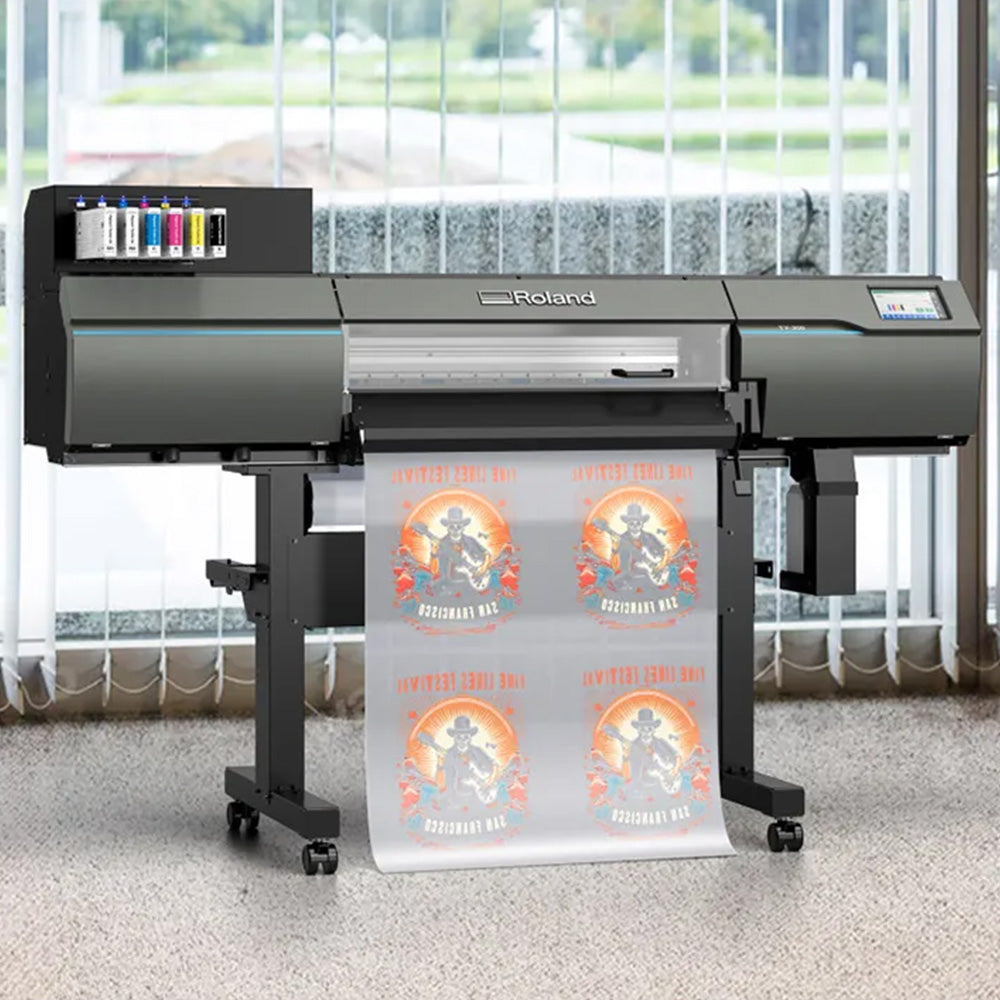

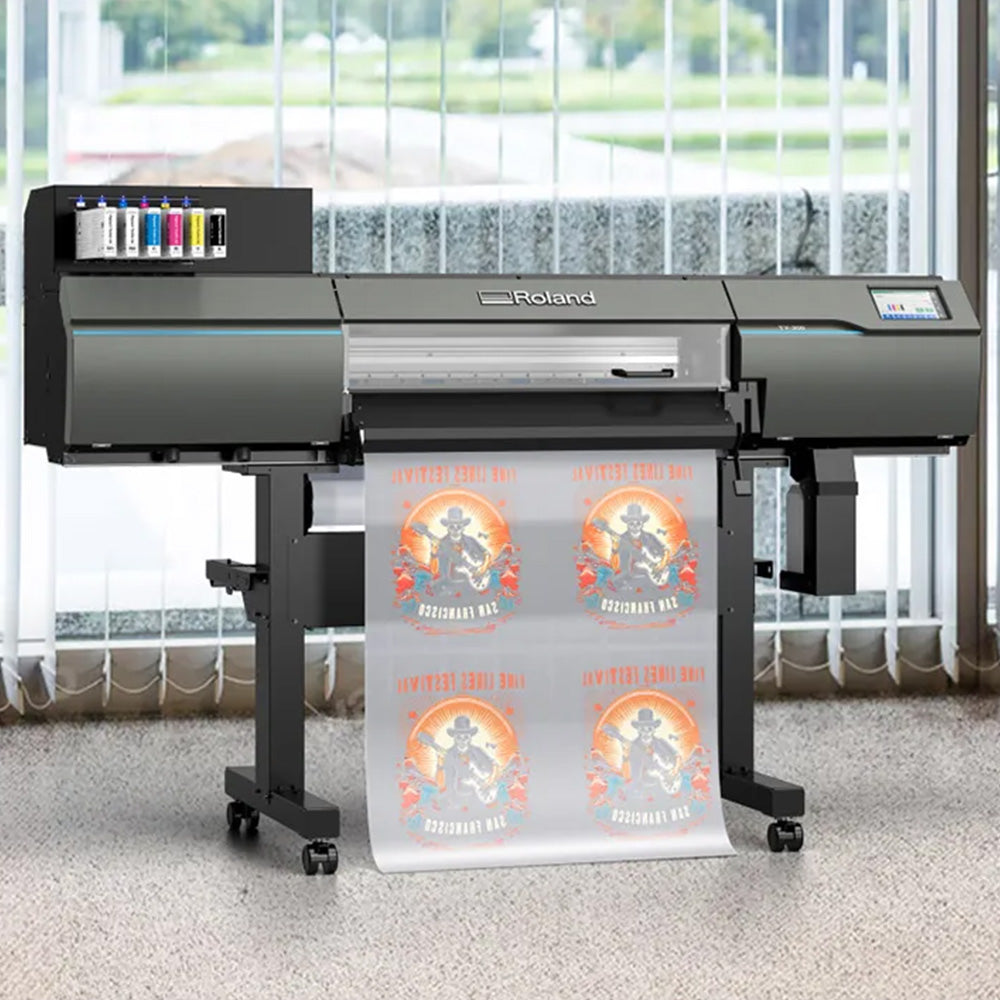

The DTF Printer That Delivers

-

Vibrant Colors

Create bold, vivid prints for any type of fabric with our exclusive DTF inks.

-

Ultra-Fine Detail

Print small letters, intricate designs, and photographs with precision. -

Maximum Productivity

Stable, high-quality printing with fast performance and minimal downtime. -

Perforated Sheet Cut

Save time by integrating perforations directly into your prints.

-

Lower Operating Costs

Produce more with less thanks to ultra-efficient operations and automatic maintenance. -

Intuitive Design

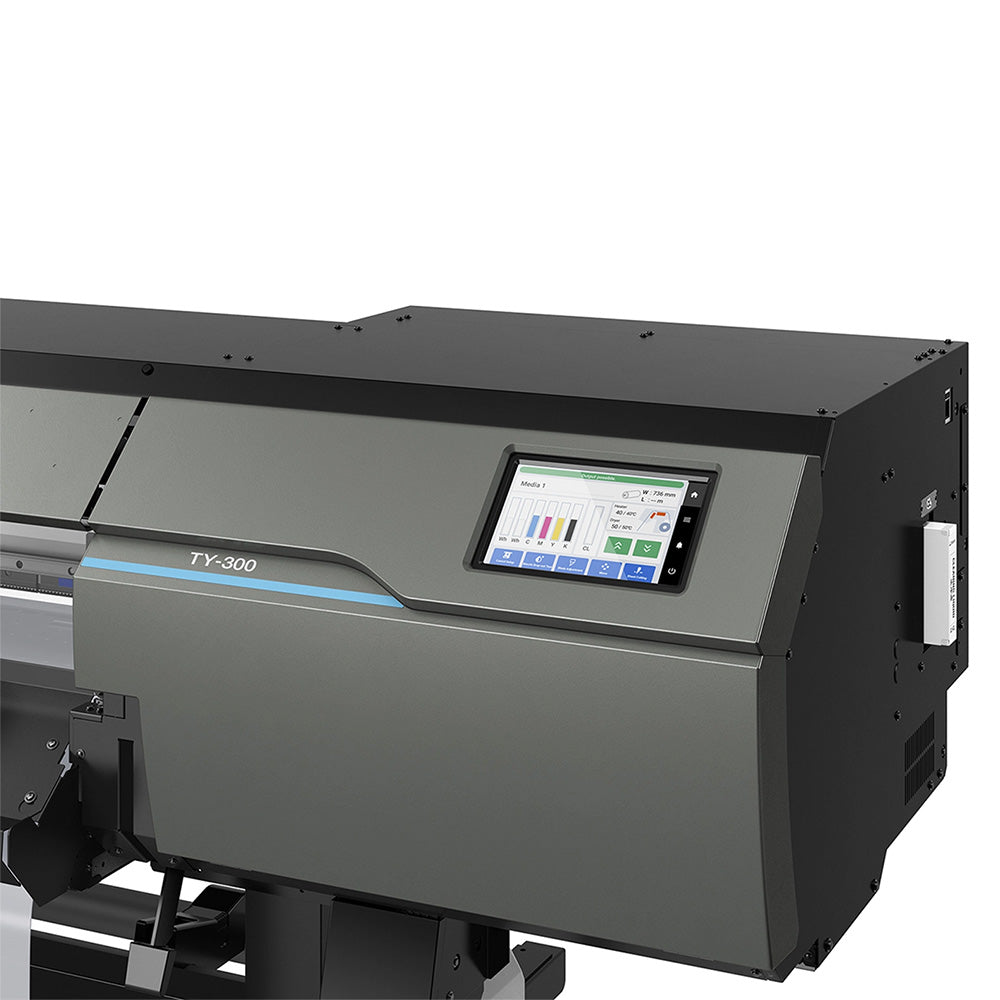

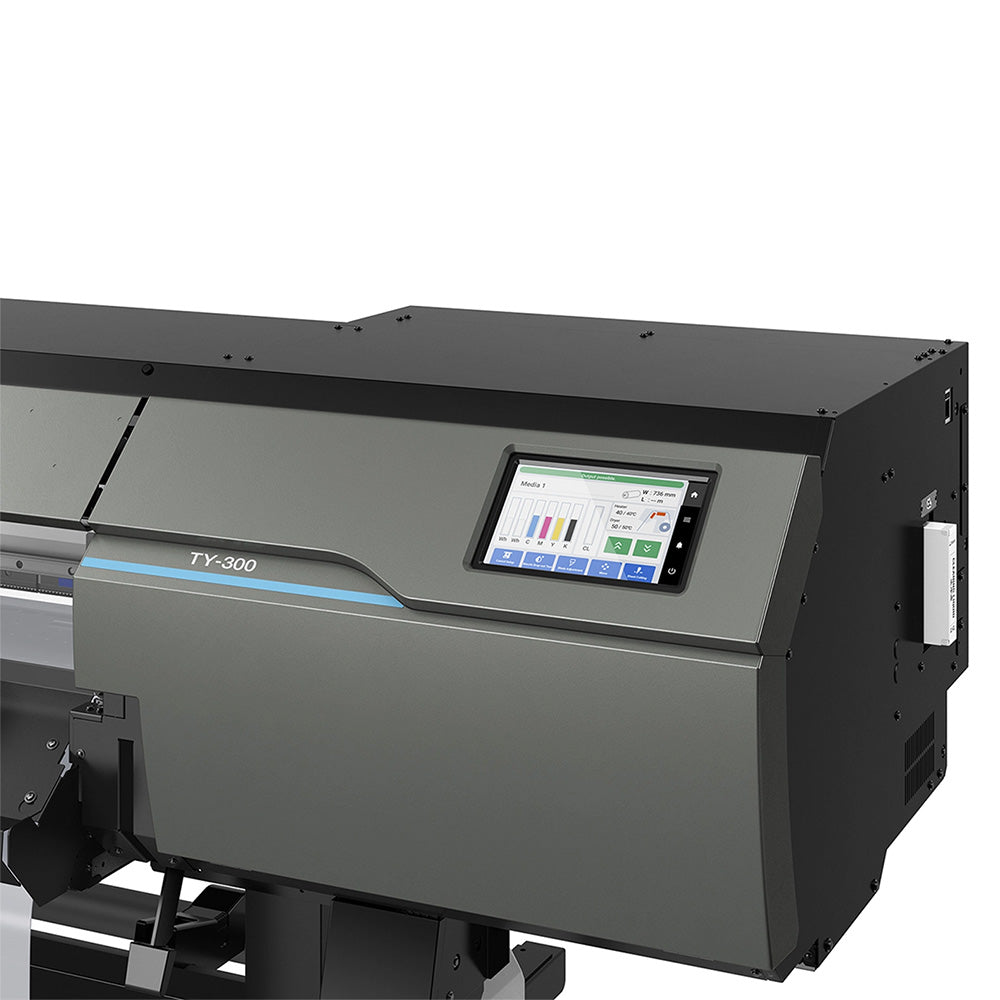

Equipped with user-friendly RIP software, a color LCD touch panel, and convenient features.

-

Powerful Performance. Maximum Productivity.

Produce spectacular results quicker and more efficiently than ever before. The TY-300 delivers stable CMYKW printing at 10.9m²/h in Production mode — 45% faster than other DTF printers on the market.Plus, with superior ink efficiency, automated maintenance sequences, and innovative features like Perforated Sheet Cut, the TY-300 streamlines your workflow and reduces cost, delivering maximum productivity and value for your business.

-

-

-

Print with Precision. Down to the Smallest Details.

Bring any print to life with the TY-300’s advanced capabilities that enable you to print small text, intricate designs, photographs, and fine details with pinpoint precision.Paired with the True Rich Color 3 setting, which ensures vivid colors, neutral grays, smooth gradations, and natural skin tones, and your prints are guaranteed to be stunning — down to the smallest details.

-

Uncompromising Safety and Compliance with Exclusive DTF Inks

Designed exclusively for DTF printing, Roland DG’s newly developed S-PG2 inks optimize printer performance and are Oeko-Tex® Eco Passport certified, ensuring your custom apparel and textiles meet the highest global safety standards.Enjoy the peace of mind knowing that your inks are free from harmful substances and are fully compliant with all international standards, including Europe’s REACH regulations.

-

-

-

Effortless Maintenance for Smooth Operations

Designed with consistent and high-quality printing in mind, the TY-300 comes equipped with automated maintenance features that keep your operations running smoothly. The printhead is automatically cleaned based on your usage to prevent nozzle dropout, while the advanced white ink circulation system minimizes ink clogging, guaranteeing stable white printing at all times.Manual cleaning has also been made easier with our new head nozzle refresher tool that effectively cleans the printhead surface. Plus, you can now replace key components, such as caps, wipers, wiper cleaners, and other items around the printhead, without needing service personnel, making upkeep simple and hassle-free.

Additional Information

-

Included VersaWorks 6 RIP Software

The latest edition of the world’s most popular RIP software comes included with the TY-300, to manage print output effortlessly right out of the box.

• When output data is loaded, the image is automatically inverted to match the DTF process, eliminating output errors.

• Five print queues, five hot folders and unlimited queue settings.

• New Job Assistant function to layout and edit cut lines in VersaWorks 6 for dual machine print-then-cut workflows.

• Advanced and easy cropping, tiling, nesting and other features.

• Match color output between different printers and print modes from a single printer with Printer Color Match Settings that integrate profiling tools such as the i1 Pro3 and new VW-S1 color measuring tool. -

-

-

Master Your Print Operations with Included Roland DG Connect App

Seamlessly manage your entire print operation from a single app — even if your business has multiple users or locations that need visibility.The user-friendly Roland DG Connect app provides you with a detailed understanding of your printers while keeping your devices running at optimum performance. Reduce downtime and improve efficiency with a machine monitoring assistant that works in complete harmony with your device.

| TY-300 | ||

|---|---|---|

| Printing Method | Piezo ink-jet method | |

| Media | Width | 7.2 to 30 in (182 to 762 mm) |

| Thickness | Maximum 39.3 mil (1.0 mm) with liner for printing, Maximum 15.7 mil (0.4 mm) with liner and 8.6 mil (0.22 mm) without liner for cutting | |

| Roll outer diameter | Maximum 9.84 in (250 mm) | |

| Roll weight | 66.1 lb (30 kg) | |

| Core diameter | 3 in (76.2 mm) or 2 in (50.8 mm) | |

| Printing/cutting width (*1) | Maximum 28.9 in (736 mm) | |

| Ink | Type | S-PG2 INK 500 ml cartridge |

| Colors | Five colors (cyan, magenta, yellow, black, and white) (2 cartridges) | |

| Printing resolution | Maximum 1,200 dpi | |

| Cutting speed | 0.39 to 11.8 in/s (10 to 300 mm/s) | |

| Blade force (*2) | 30 to 500 gf | |

| Blade type | CAMM-1 series blade | |

| Blade offset | 0.0 to 59 mil (0.000 to 1.500 mm) | |

| Software resolution (cutting) | 0.98 mil/step (0.025 mm/step) | |

| Media heating system (*3) | Print heater set temperature: 86 to 113°F (30 to 45°C), Dryer set temperature: 86 to 122°F (30 to 50°C) | |

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | |

| Power-saving function | Automatic sleep feature | |

| Rated input | 100-120 / 220-240 Vac 50/60 Hz 6.4/3.0 A | |

| Power consumption | During operation | Approx. 840W |

| Sleep mode | Approx. 70W | |

| Acoustic noise level | During operation | 63 dB (A) or less |

| During standby | 58 dB (A) or less | |

| Dimensions (Width x Depth x Height) | 80 in x 29.5 in x 55.8 in (2,032 mm x 748 mm x 1,415 mm) | |

| Weight | 298 lb (135 kg) | |

| Environment | During operation (*4) | 68 to 82.4°F (20 to 28°C), Humidity: 40 to 60% RH (no condensation) |

| Not operating | 41 to 104°F (5 to 40°C), Humidity: 20 to 80% RH (no condensation) | |

| Included Items | Dedicated stand, Power cord, Media holders, Separating knife, Replacement blade, Cleaning liquid, Drain bottle, User's Manual, Software(VersaWorks, Roland DG Connect), etc. | |

| *1 | The length of printing or cutting is subject to the limitations of the program. |

| *2 |

|

| *3 | Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating environment. Depending on the ambient temperature and media width, the preset temperature may fail to be reached. |

| *4 | Operating environment (Use in an operating environment within this range.) |

|

- Dedicated stand

- Power cord

- Media holders

- Separating knife

- Replacement blade

- Cleaning liquid

- Drain bottle

- User’s Manual

- Software (VersaWorks, Roland DG Connect)

Built to build your business and engineered to a higher standard, the TrueVIS TY-300 is supplied with a One-Year Trouble-Free Warranty for added peace-of-mind.

Is the Roland TY-300 Roll-To-Roll DTF Printing System right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Roland TY-300 Roll-To-Roll DTF Printing System to your apparel decorating business.