Features And Highlights

-

Why It's Better

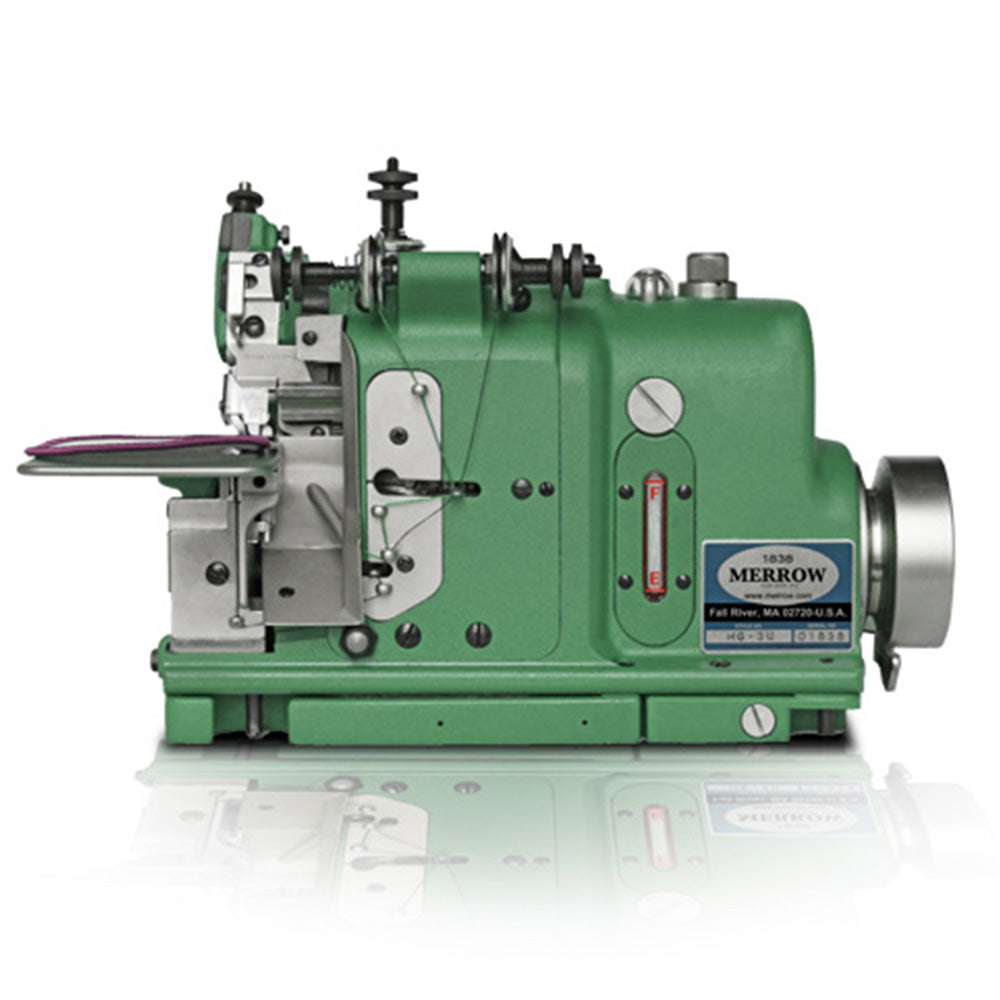

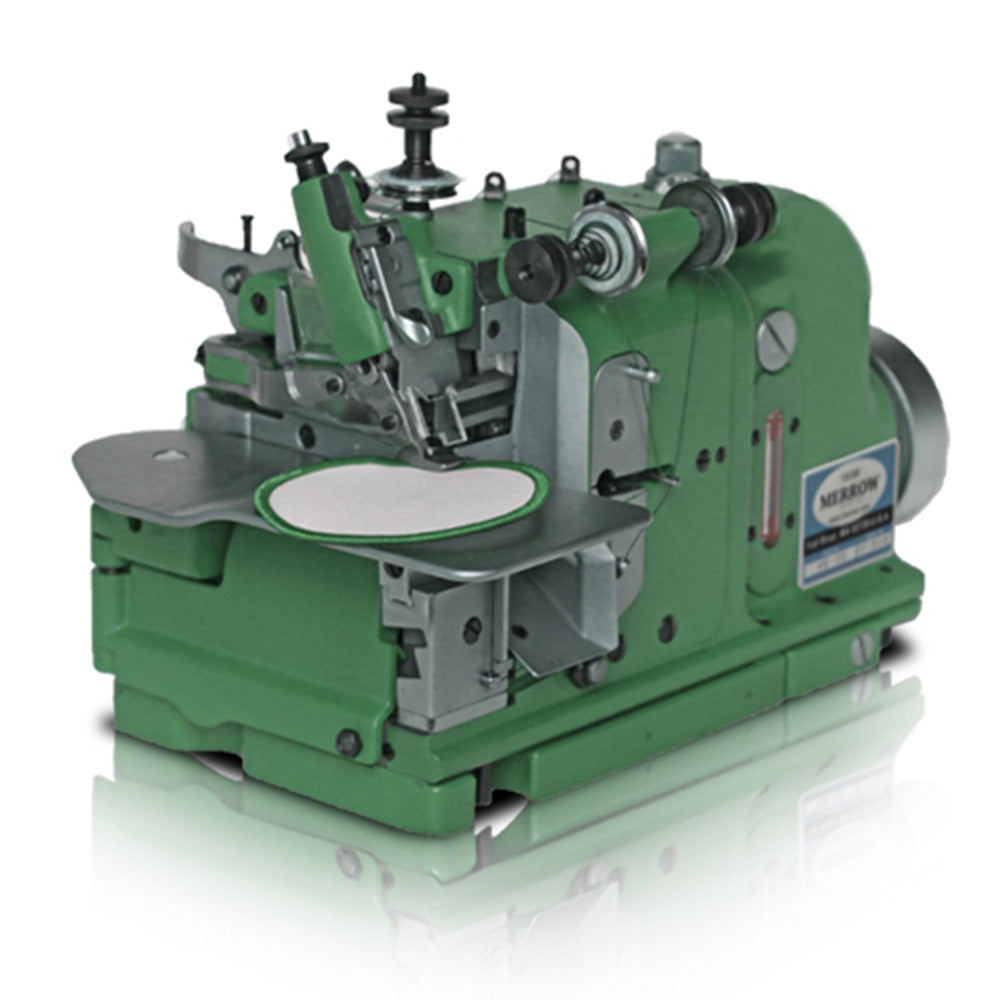

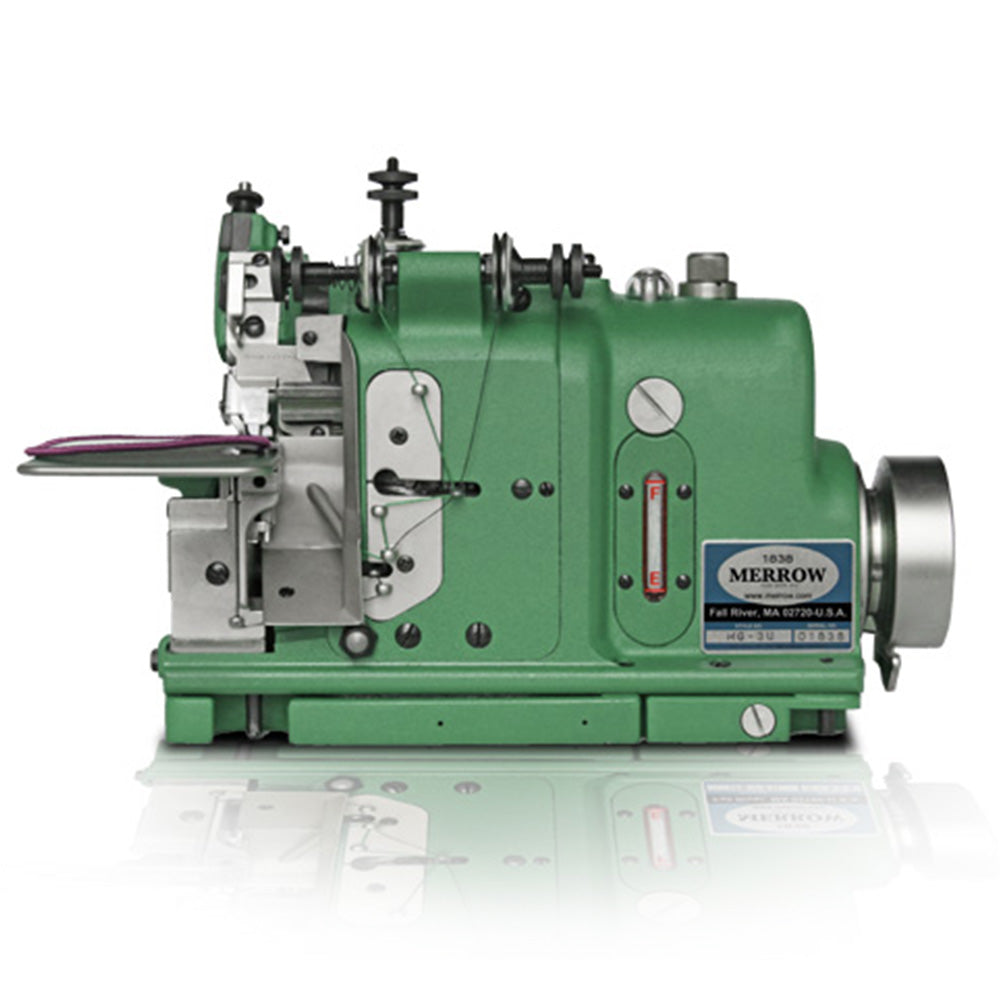

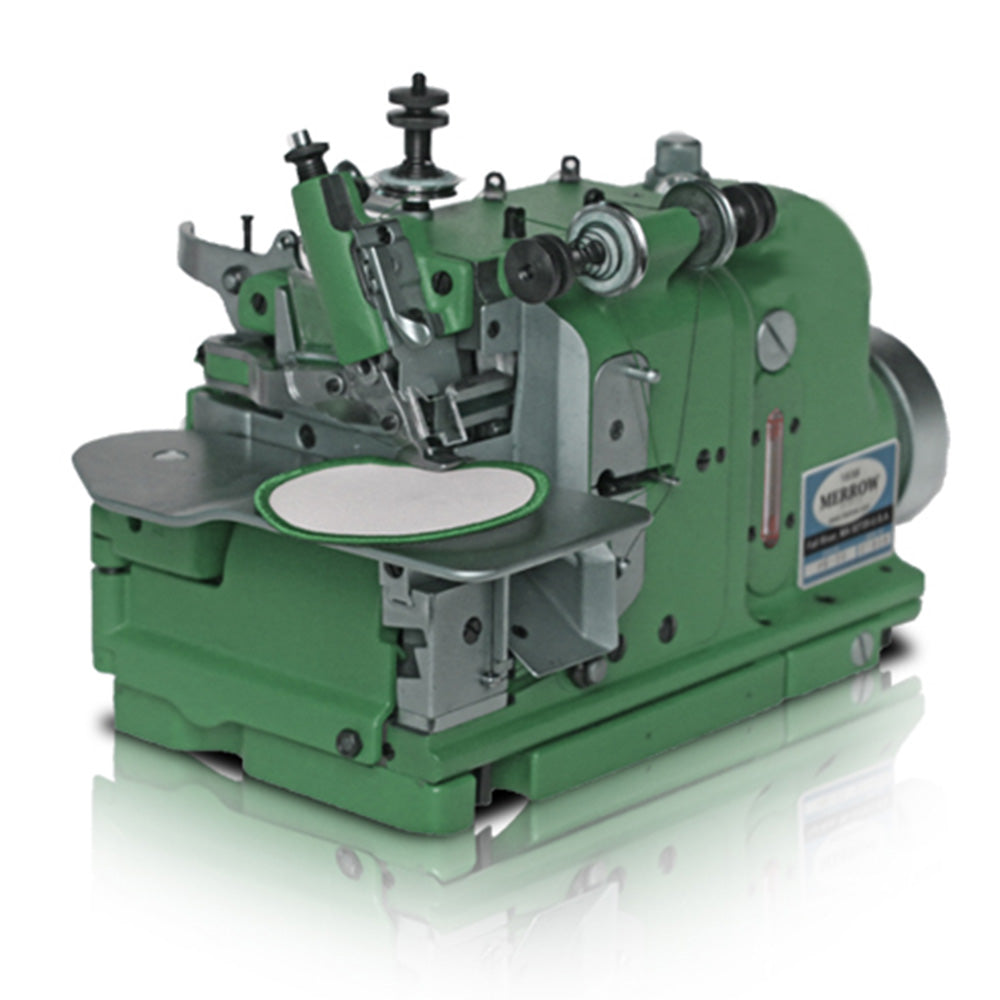

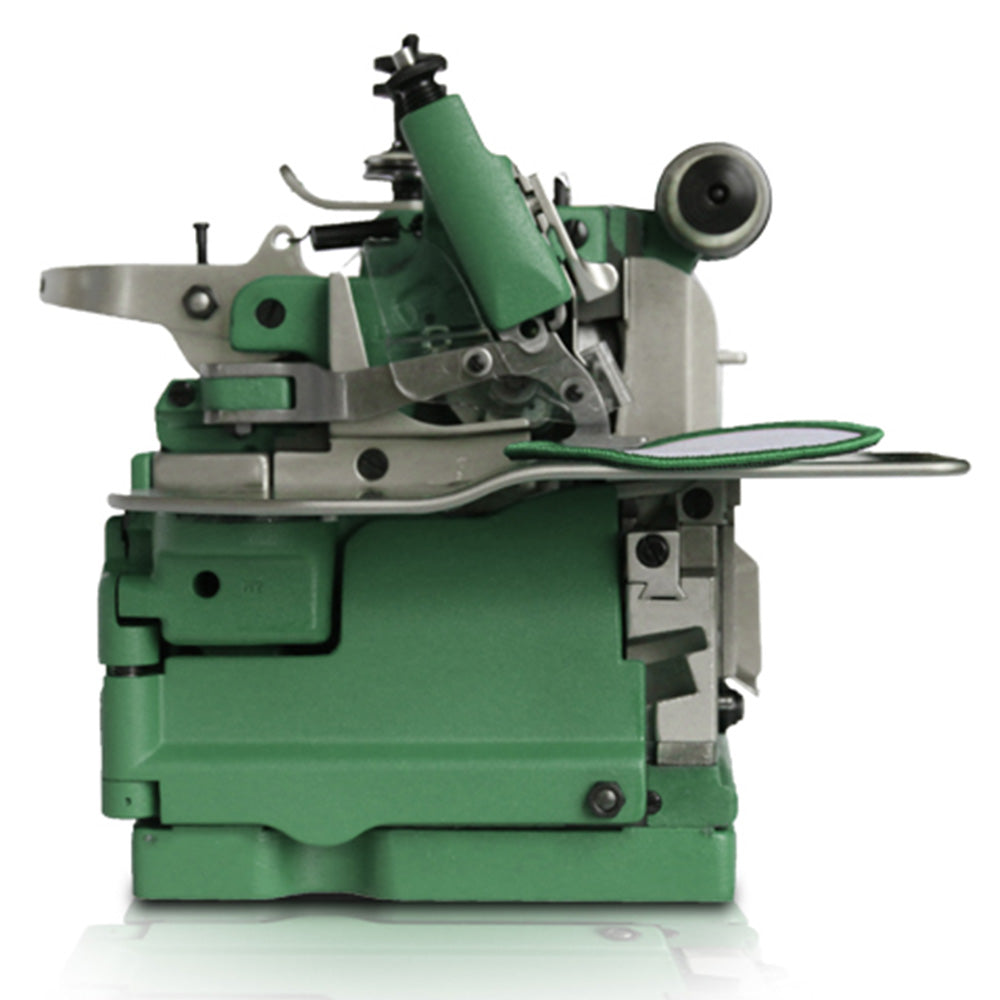

The Merrow Edge is the standard bearer for emblem edging on smaller patches, badges, and insignias. Noticeable for its finish and regularity, the Merrow Emblem Edge is a distinctive mark of quality that can only be made by the Merrow MG-3U.

-

How It's Better

The MG-3U uses lightweight moving parts and needle bearings that are manufactured to extremely high tolerances, permitting the fast and smooth starts and stops inherent in intermittent operations like emblem edging. As a result, sewing edges on an MG-3U assures a uniformly finished, unmatched stitch.

-

Where It's Used

The MG-3U is a versatile industrial machine that will satisfy the needs of the local emblem shop to the factory producing thousands of patches per day.

Additional Information

- Quality of Materials

Our parts and machines are handcrafted and handbuilt

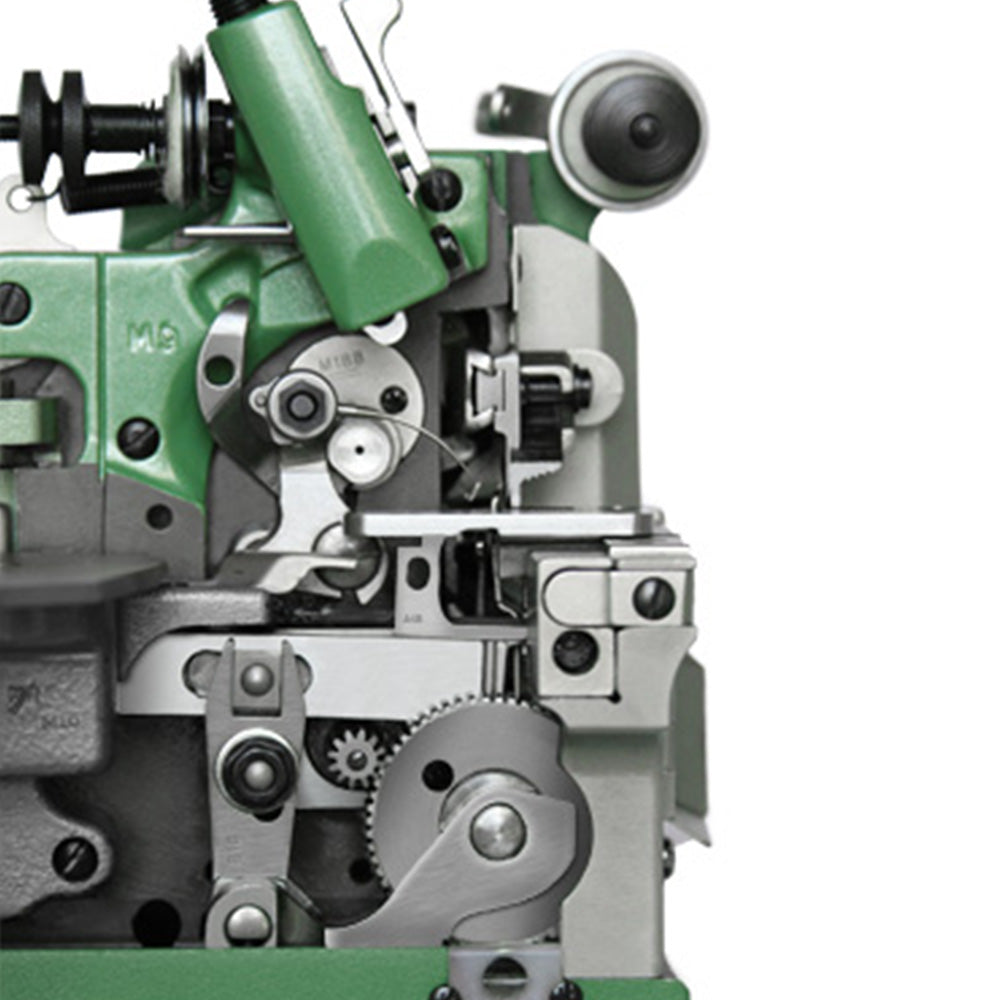

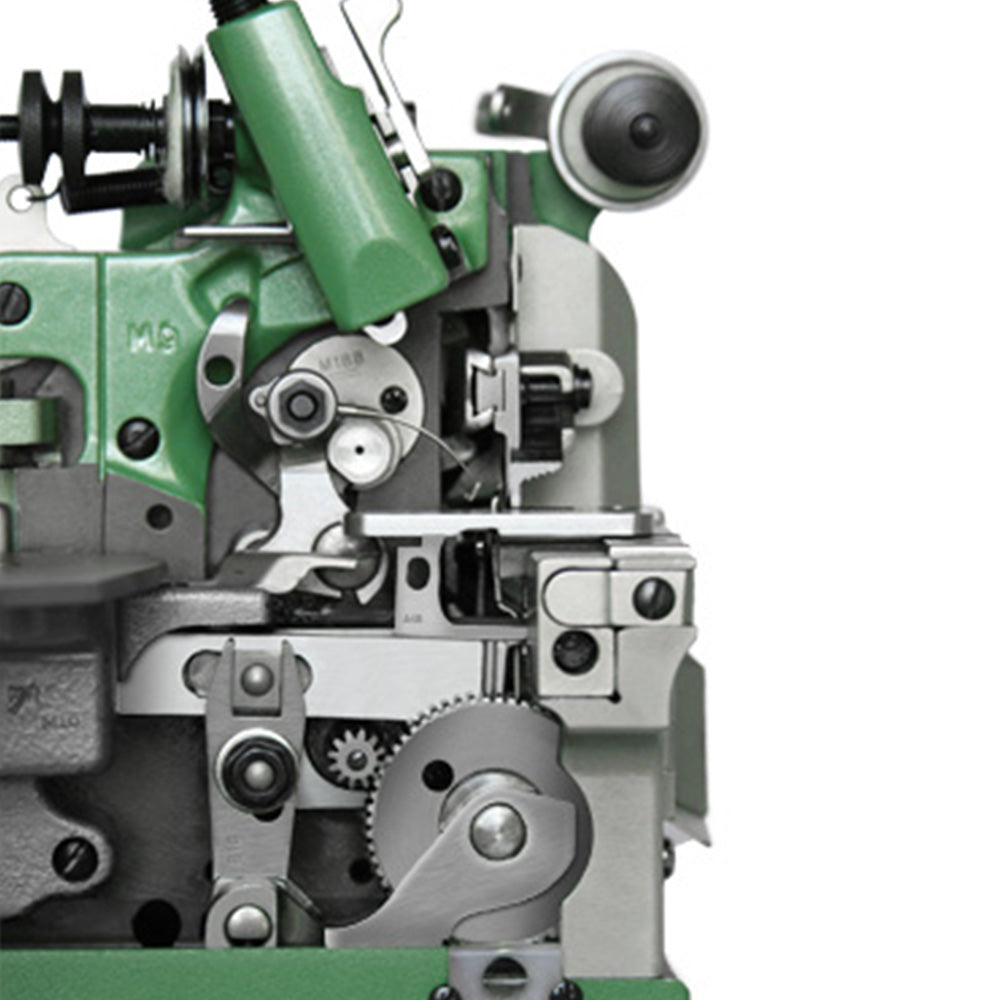

- Cams NOT pistons -- Proprietary Cam Technology - Different from all other Sewing Machines

We're the only manufacturer in the world building Cam-driven sewing machines that stand up to heavy use. Merrow's Cam-driven machines produces a superior quality stitch. Using sophisticated 5-axis computerized milling machines, we've succeeded in developing proprietary high-technology components offering faster, quieter, operation and remarkable durability.

- Merrow Cams are Machined to Exacting Dimensions

Tolerances are held to .001: the tightest in the industry. They have been designed to operate continuously between 2200 and 5500 RPM. Merrow Cams allow a Merrow Machine to create a perfect stitch while ensuring that the sewing machine will last a lifetime.

- Special consideration should be paid to the intricacies of Merrow's Cam Technology

The Cam groove width and the final surface finish of the Cam groove are created with proprietary manufacturing technology that allows all sides of Merrow's Cam to have an equal, highly polished and uniform steel surface, this results in an approximate coefficient of friction, when lubricated, of .06 or lower.

Cam gear teeth are cut to a unique specifications with the sides of each tooth shaved to create a proprietary profile. This reduces heat when running.

Hardness and metallurgy of the Cams are continuously modified, improving the durability of the Cam. The Benchmark for the durability of a Merrow Cam in continuous operation is more than 30 years of operation without failure.

Sew thousands of different Material Types. Woven Fabric, Knit Fabric, Terry Towel, Denim, Technical Textiles AND Nonwovens. While the machines sew exceptionally on mid-weight woven fabrics, it performs well on a huge number of materials from vulcanized rubber to fiberglass to insulation.

With more than 645 different needle plates and feed dogs, we can modify the stich to accommodate more demanding fabrics.

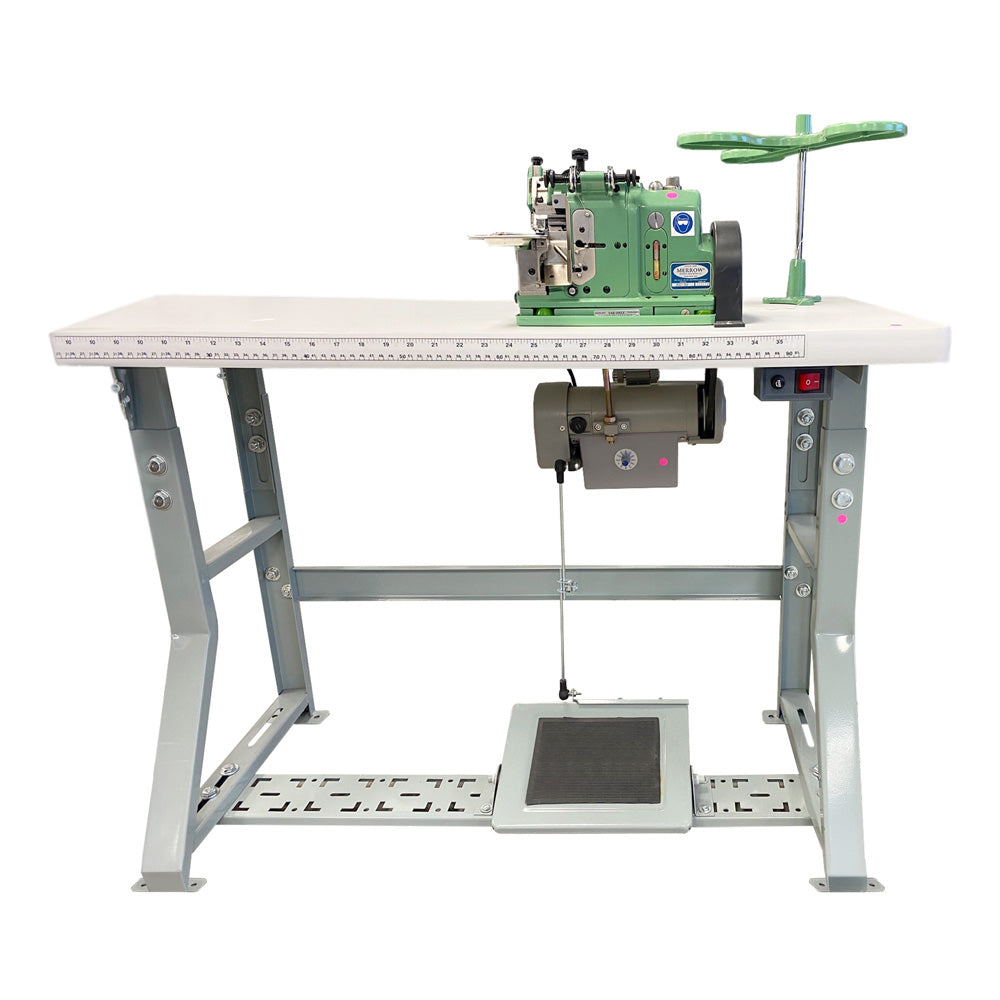

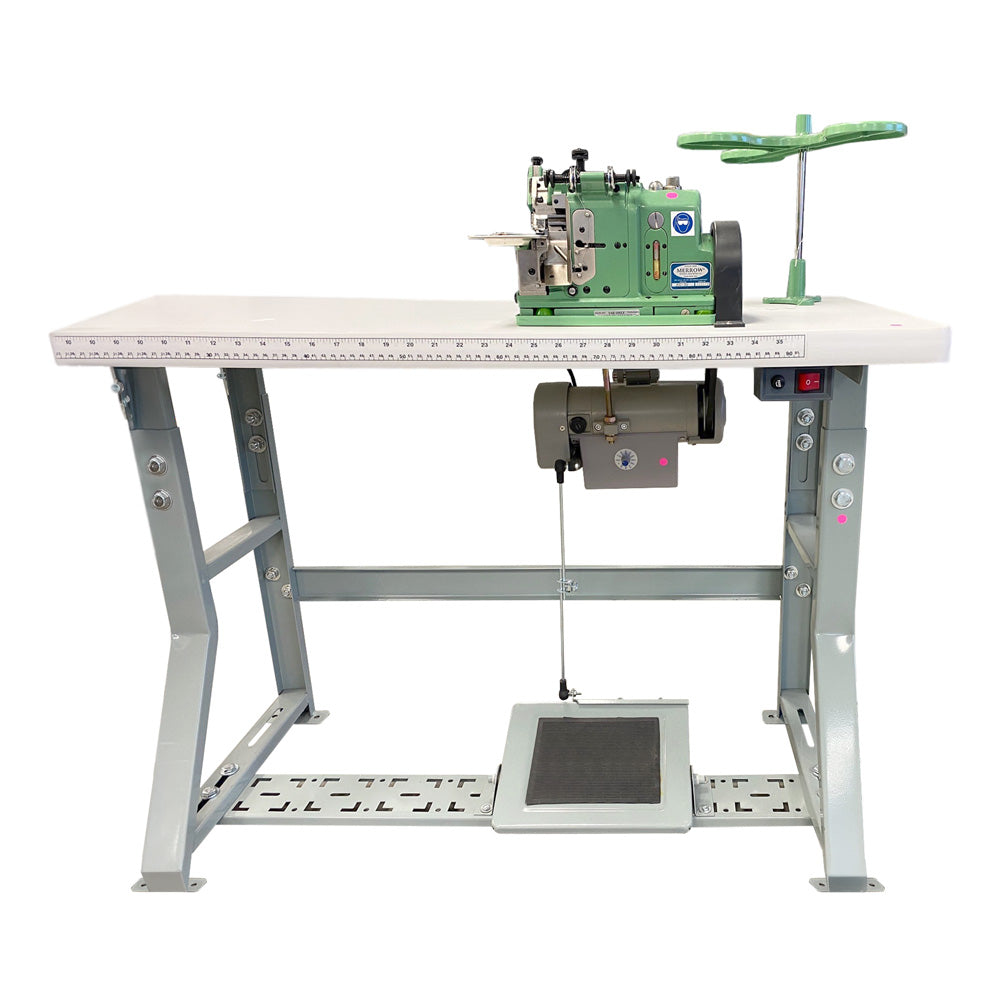

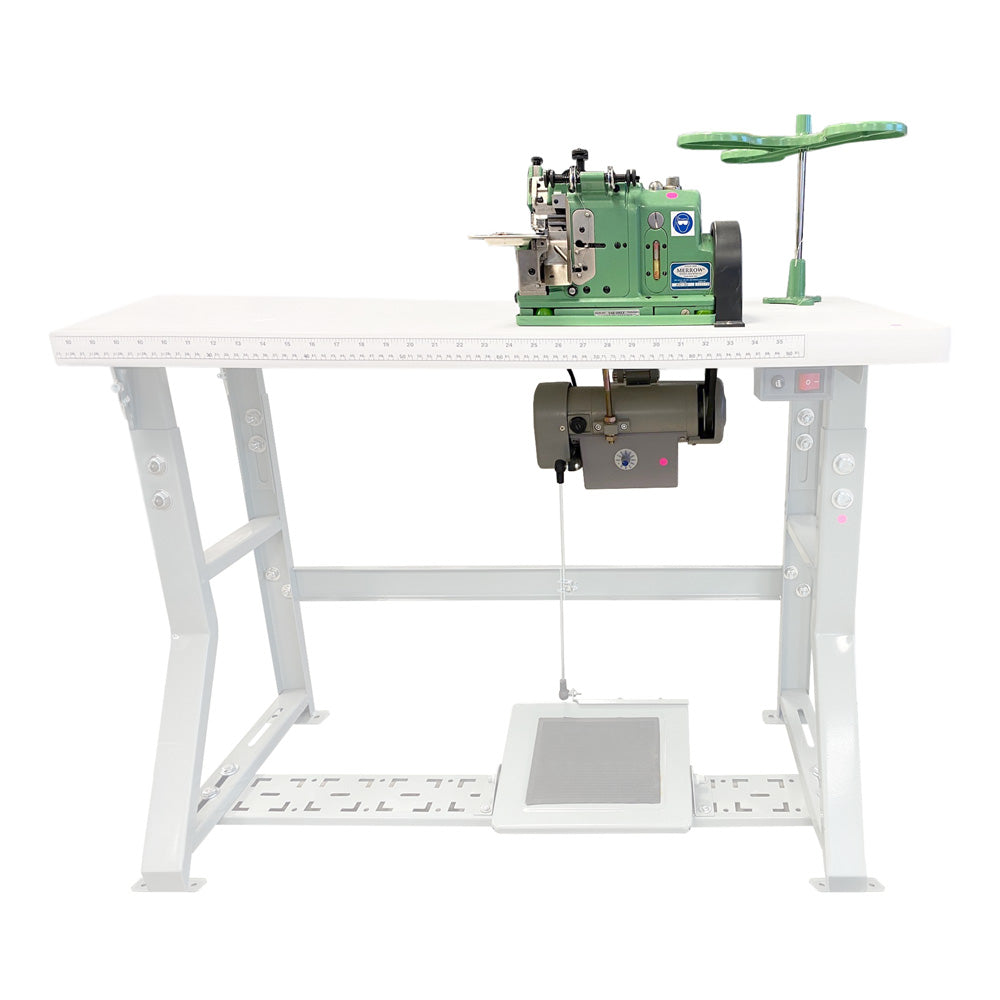

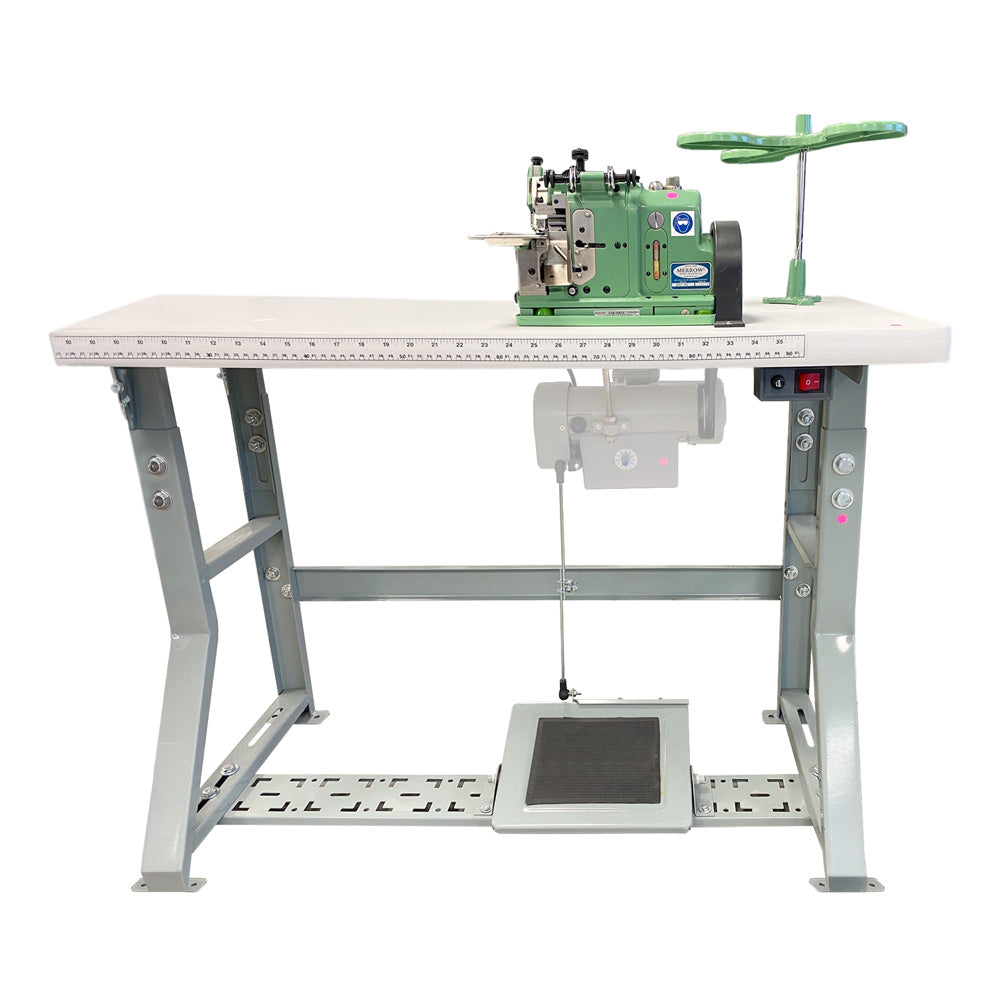

Machine Brand: Merrow

Machine Model: MG-3UW

Machine Type: Hook & Loop 3 thread machine

Edging Stitch Width: 3/16" to 3/8" (Depending on material thickness)

Thread Stand: Included

| MAX OPERATING SPEED | 5500 RPM |

| MAX STITCH WIDTH | 3/16" |

| STITCH RANGE | 20 - 40 SPI |

| STANDARD NEEDLE | MERROW 4SDT |

| MERROW NEEDLE RANGE | MERROW 3SDT-5SDT |

| FEDERAL STITCH TYPE | 505 |

| NUMBER OF THREADS | 3 |

| WARRANTY | 1 Year |

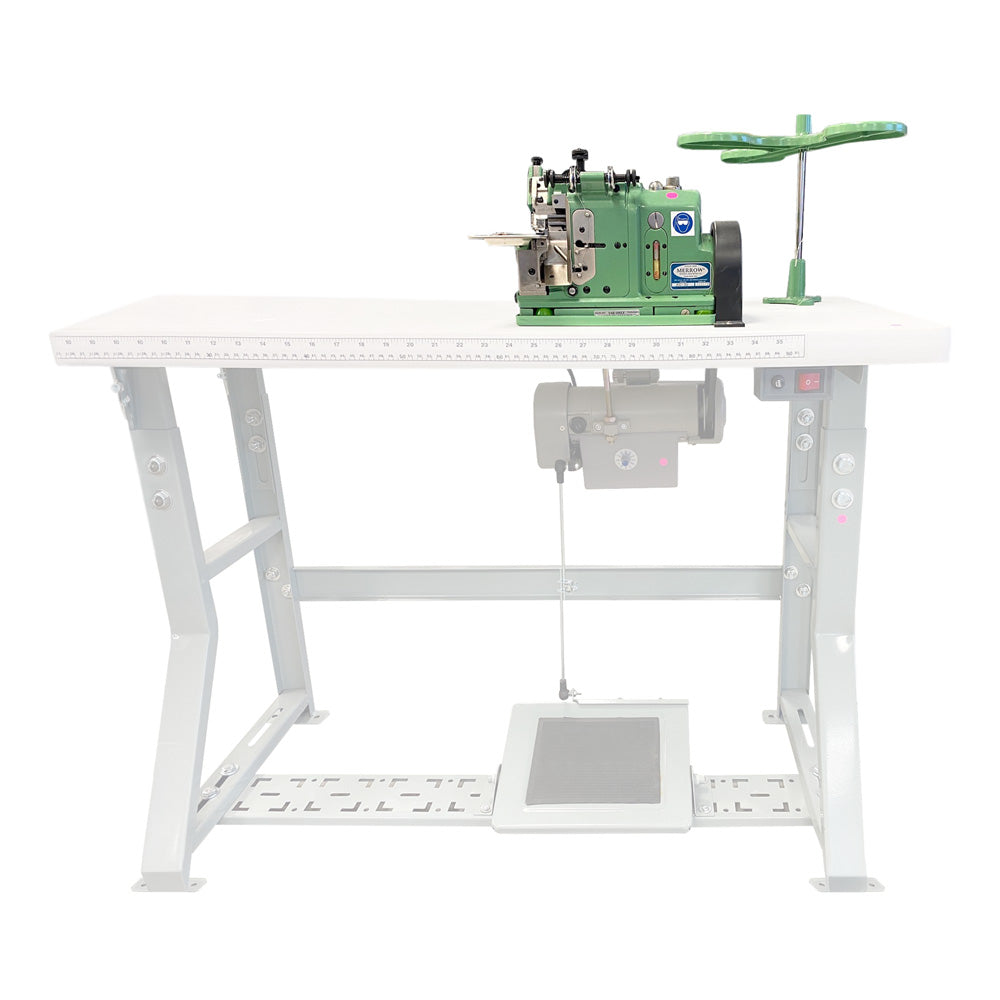

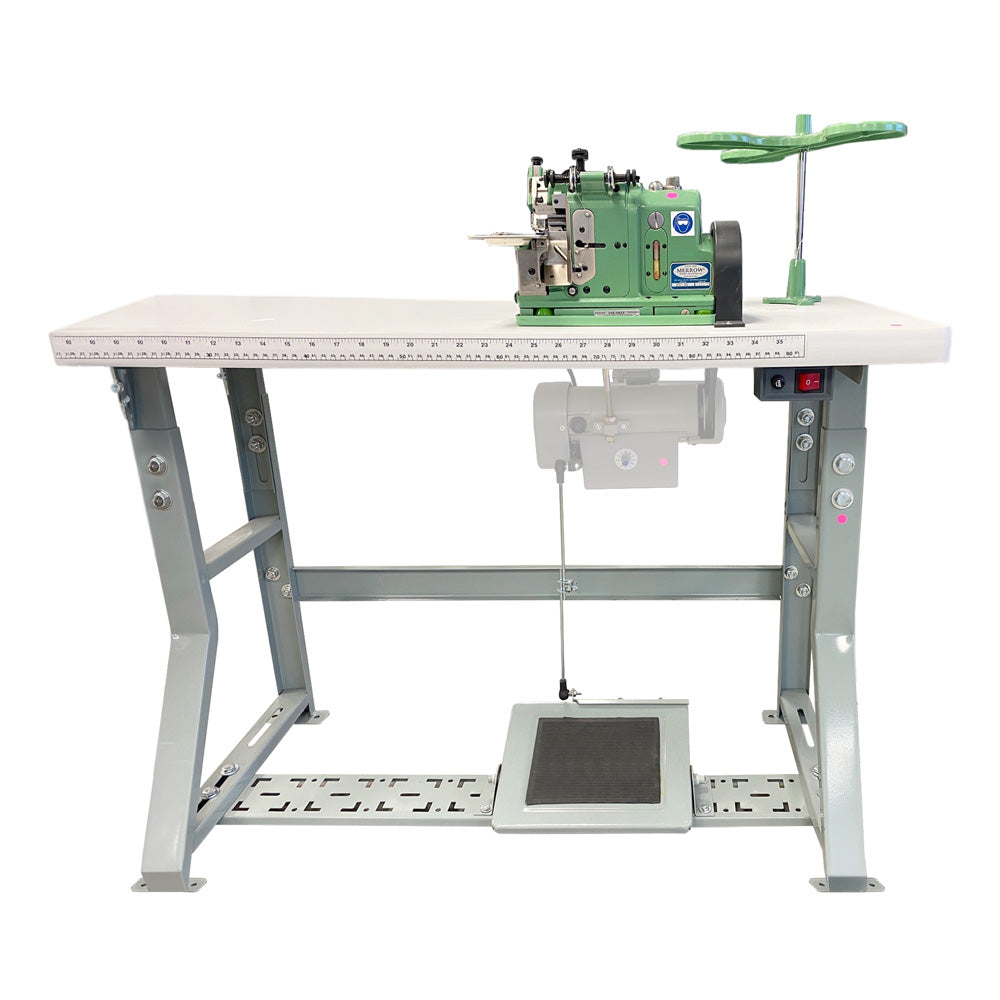

Motor Type: Servo Motor

Voltage: 110

Phase: 1

Watts: 550

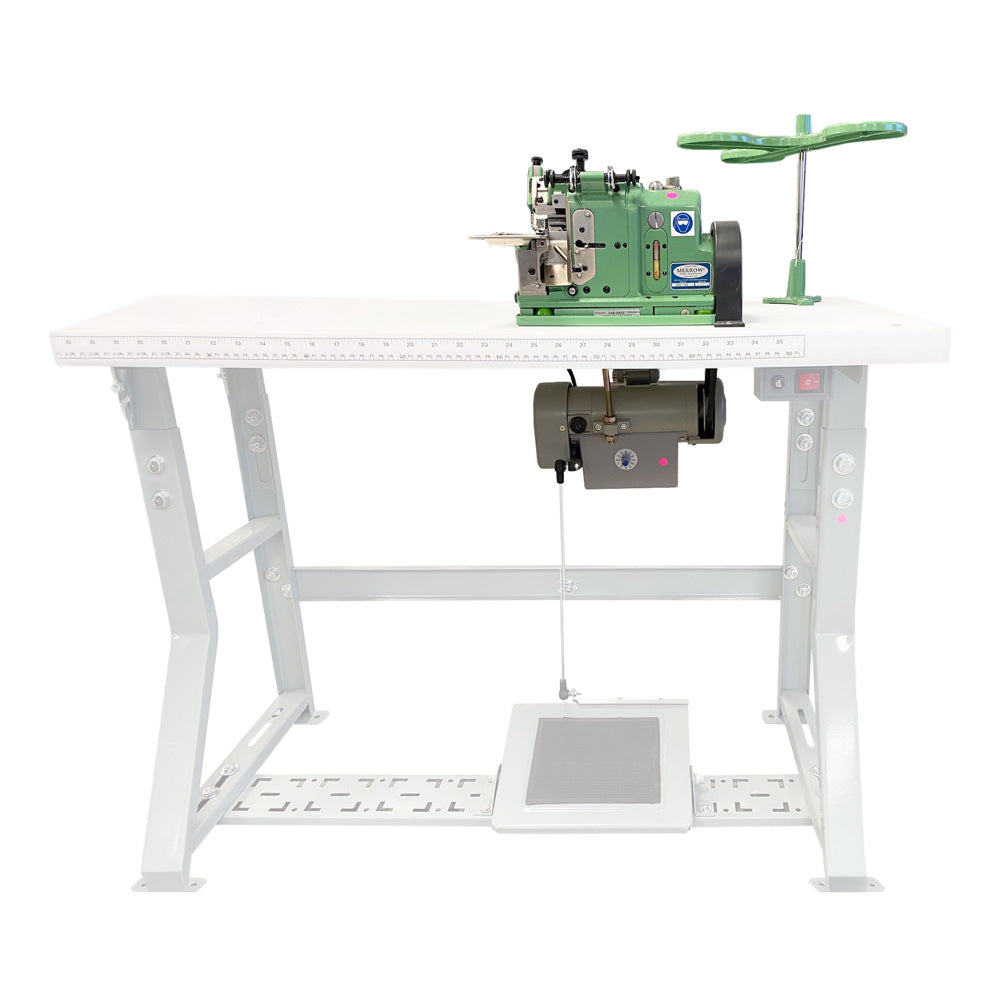

Stand/Legs Type: Standard

Table Type: 20"x 48" Top Mount Table

Solid 20"x48" height adjustable table top

Is the MG-3U right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the MG-3U to your apparel decorating business.