Additional Information

- High gel, gloss appearance, low-tack feel

- Use as foil or flock adhesive

- Use as an overprint clear to enhance color vibrancy and create gloss surfaces

- Use as a High Density Clear, either on its own or tint with color

- Excellent adhesion to fabrics, stretch properties, and wash durability

Fabric Types

- 100% cotton, blends, spandex, uncoated nylon, acrylic

Mesh

- Counts: 24-110 t/in (9-43 t/cm)

- Tension: 25-35 n/cm

Squeegee

- Durometer: 60/90/60, 60-70

- Edge: Square, Sharp

- Stroke: Hard flood, Slow stroke

- *Do not use excess squeegee pressure

Non-Phthalate Stencil

- Direct: 2 over 2

- Off Contact: 1/16” (.2cm)

- Emulsion Over Mesh: 15-20% or 200-400 micron

Flash & Cure Temperatures

- Flash: 220°F (105°C)

- Cure: 320°F (160°C)

Pigment Loading

- up to 10% Wilflex PC

- up to 15% Wilflex EQ

- up to 40% Wilflex RIO / MX

- up to 30% Rutland C3 Boosters

Epic Additives

- N/A

- *All percentages listed at % by weight

Shipping & Storage

- 65-90°F (18-32°C)

- Avoid direct sunlight.

- Use within one year of receipt

Clean Up

- Ink degradent or press wash

- Use consistent, high-tensioned screen mesh and sharp edged squeegees for best print results. Recommended mesh counts can vary depending on particle size

- For best HD results, use open mesh counts with 200 - 400 micron capillary film and print-flash-print. Use a heavy flood to fully fill the open areas of the stencil with ink then print with medium squeegee pressure

- Print in last position or flash after each print if using multiple screens

- Commonly used as a foil or flock adhesive

- Tintable with plastisol colorants. See Pigment Loading section for suggested tinting percentages. Adjust the % colorant added based on the strength of the colorants and color saturation desired

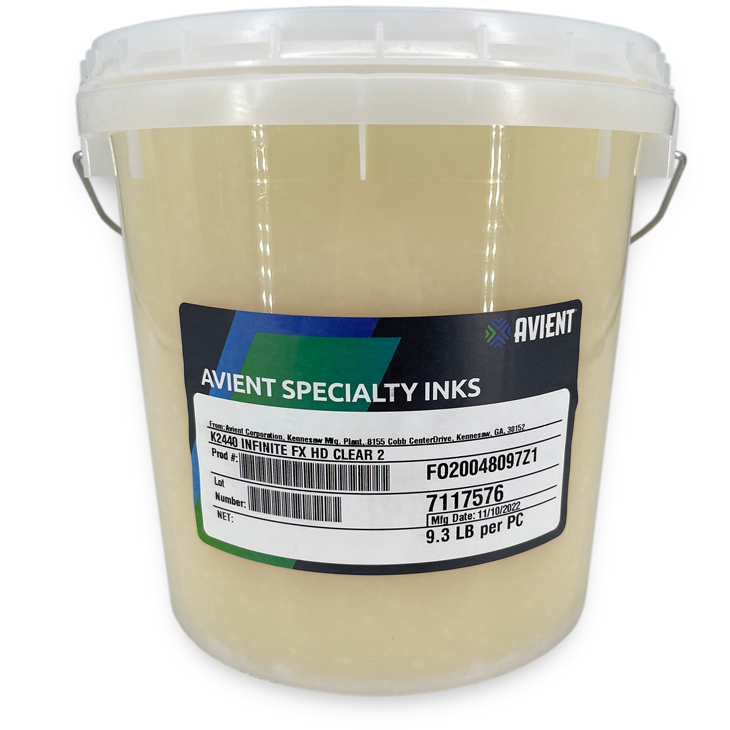

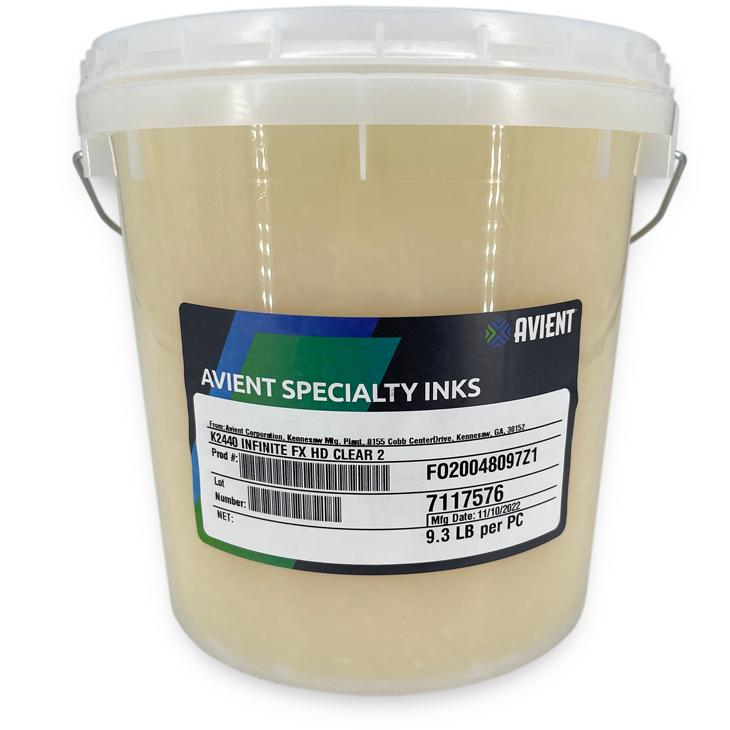

- Amber appearance in the bucket but will gain transparency after cure. Achieves good clarity at high ink deposit

- For flock adhesion, print using 70 duro squeegee 86-110 t/in (34-43 t/cm) with 200 micron stencil and then apply the flock fibers onto the wet ink layer and cure at 320°F (160°C)

- For improved flock adhesion, add up to 5% INFINITE FX HUGGER CATALYST. Adding N/A Hugger Catalyst reduces pot life to 4-8 hours

- For foil transfers, print HD Clear 2 using 70 duro squeegee and 86-110 t/in (34-43 t/cm) and 2 strokes. Place foil face up with teflon sheet and apply foil with heat press at 330°F (165°C) for 10-12 sec at medium pressure. Cool shirt before peeling foil. HD Clear 2 can be used as a foil adhesive after cure with a heat press or with an automatic in-line press foil application.

- Stir plastisols before printing.

- Do not dry clean, bleach or iron printed area.

- Perform fusion tests before production. Failure to cure ink properly can result in poor wash fastness, inferior adhesion and unacceptable durability. Gel and cure temperatures for ink should be measured using a Thermoprobe device placed directly in the wet ink film and verified on the substrate(s) and equipment to be used for production.

- It is the responsibility of the printer to determine that the correct ink has been selected for a specific substrate and the application processes meet the printer’s customer standards or specifications.

- Curing is the responsibility of each printer to confirm that the print is fully cured. PolyOne’s cure recommendations are not a guarantee or warranty, but merely suggested starting points for curing evaluations as explained above.

- When printing on garments that contain certain dyes, you must pre-test for the potential ghosting. Please refer to our website for more information on this issue.

- Wilflex products have been carefully designed to perform within a given viscosity range, and any dramatic change in viscosity is probable to result in a change in printing characteristics

- NON-CONTAMINATION OF EPIC INKS: Do not mix EPIC inks with inks, additives or extenders from other companies. All buckets, palette knives, stirring apparatus, squeegees, flood bars and screens must be cleaned properly and free of phthalates and pvc containing inks. Non-phthalate emulsions and pallet adhesives must be used. Failure to follow these precautions may cause phthalate contamination in violation of consumer protection laws and regulations.

- Any application not referred in this product information bulletin should be pre-tested or consultation sought with Wilflex Technical Services Department prior to printing.