Often Purchased With

-

POPULAIRE

Mimaki Encre PHT50 DTF (compatible avec la série TxF)

I-PHT50-W-50-1Prix habituel $114.00 CADPrix habituelPrix unitaire par -

Mimaki Flushing Liquid FL-003-Z-22 (Compatible with TS100-1600 / TxF Series)

C-FL003-Z-22Prix habituel $41.00 CADPrix habituelPrix unitaire par

Additional Information

The process starts with a DTF printer laying down specialized inks onto special plastic PET films. These films are known as DTF Transfer Films. Then, DTF hot-melt adhesive powder, a white granular product, is applied to the printed transfer film. The powder is evenly applied to the film with a powder shaker. The powder only sticks to the areas that have ink on them. The powder shaker literally shakes off the excess powder off the film. The film is then transported into a small curing oven that is used to melt and bind the hot melt powder onto the transfer film. The hot-melt adhesive does not actually release fumes at this stage because of the nature of the thermoplastic adhesives used.

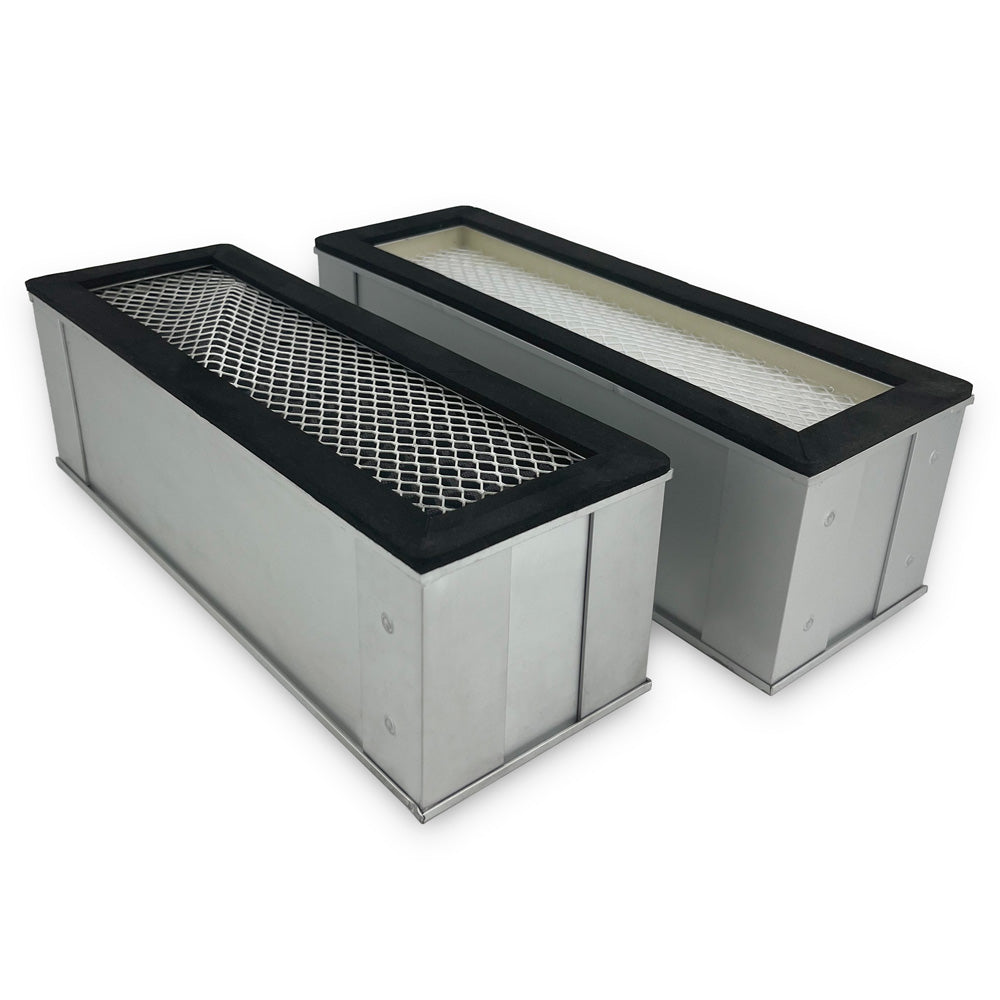

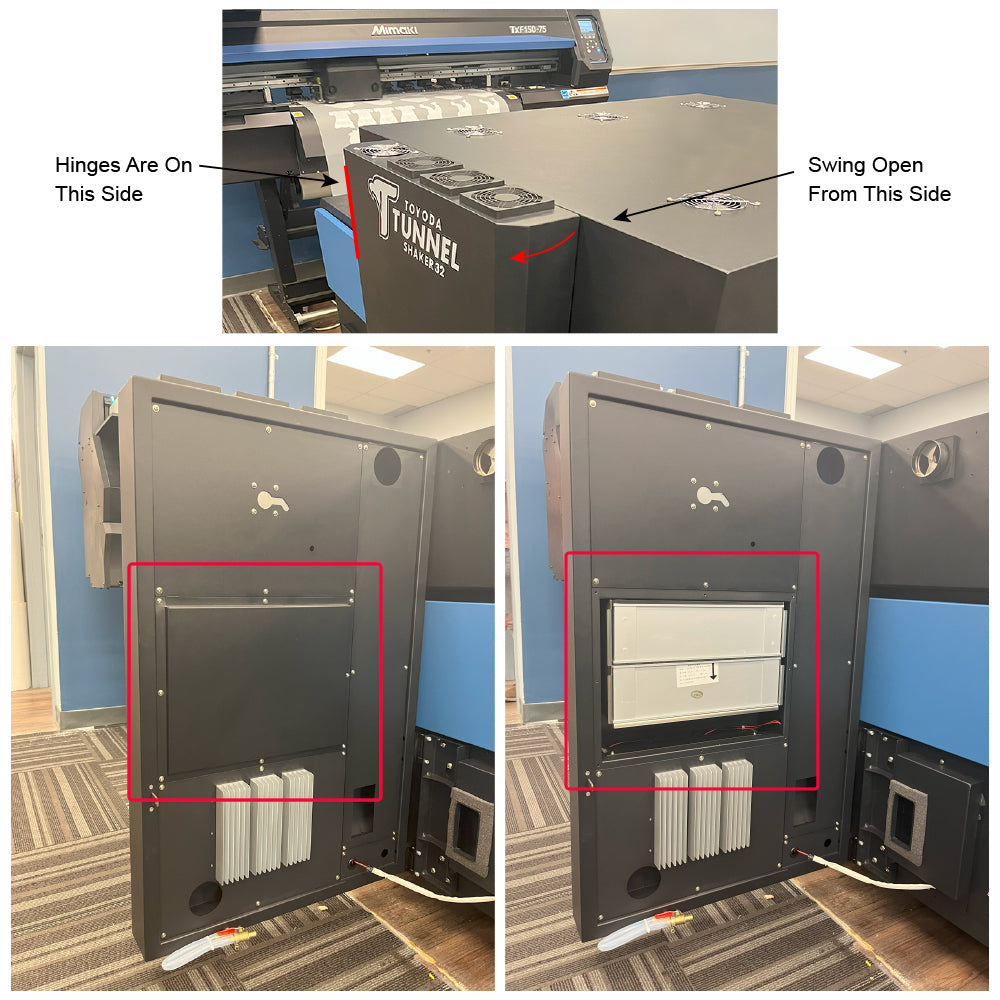

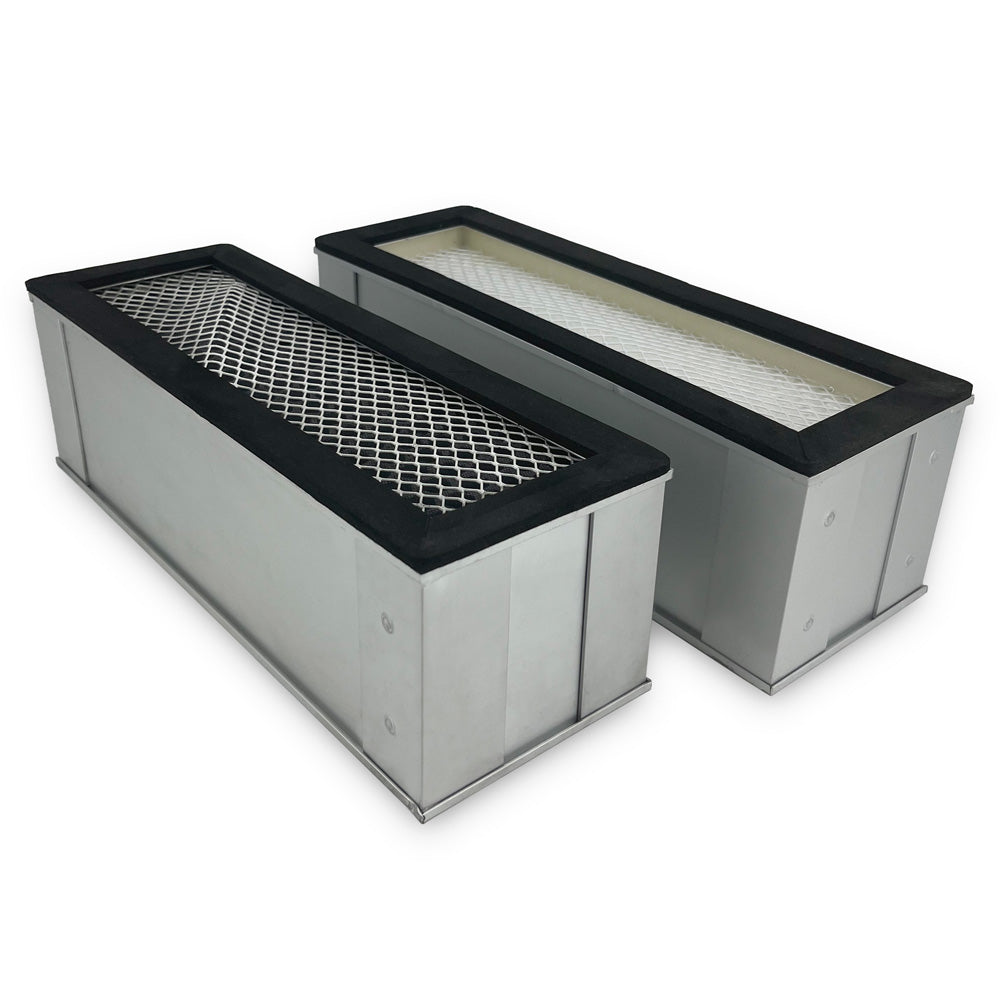

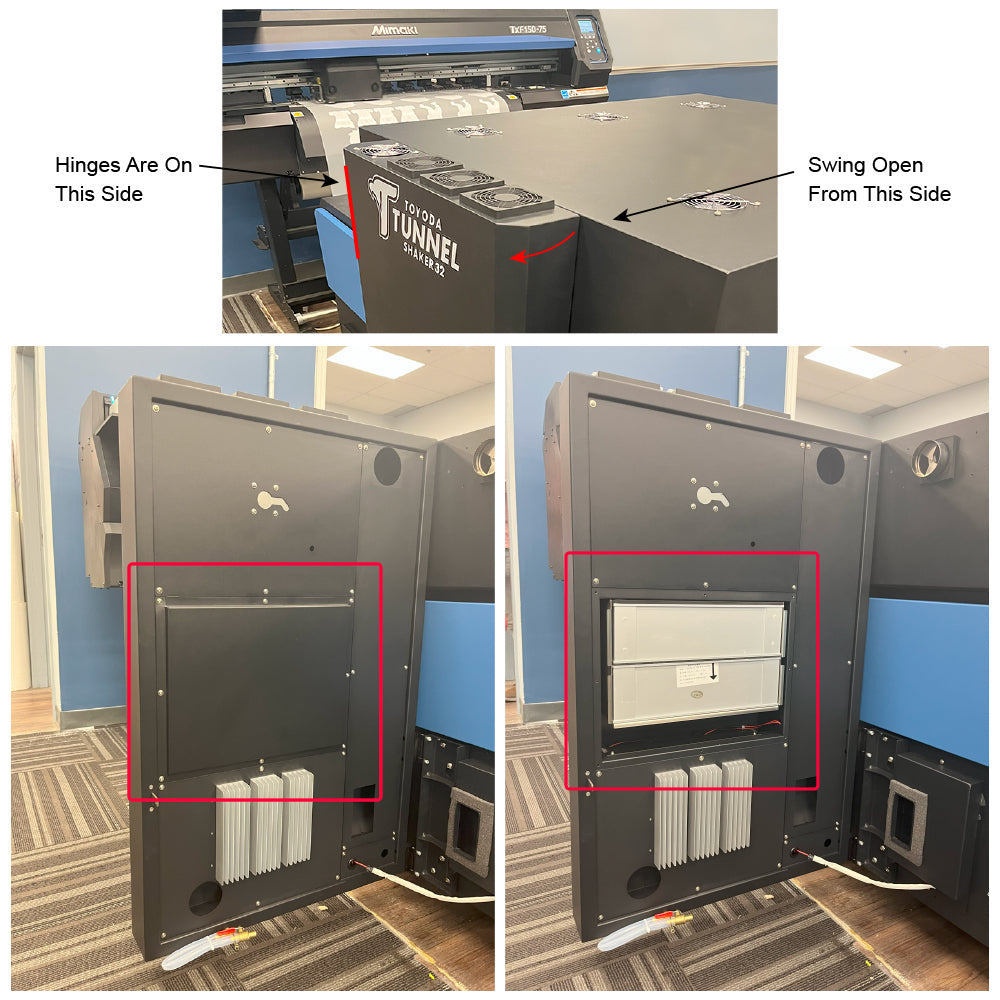

However, the oven boils away the excess liquid from the inks and creates a fog. The dense, oily fog is made up of a concentration of tiny liquid droplets. This is where fume extraction is required. The HEPA and Charcoal filters are specifically designed to capture these microscopic droplets. This is necessary to keep the work environment, product and equipment clean and fog-free.

Once the transfer film is complete with ink and adhesive layers applied and oven cured, a Heat Press is used to transfer the designed embellishment onto fabric or garment without any additional release of fumes.

WORK IN A WELL VENTILATED AREA and use Protective Equipment when working with DTF products and processes as fumes may be hazardous. DTF inks and film require a good humidity environment - over 40% humidity is highly recommended to minimize risk of ink clogs and film buckling.