Additional Information

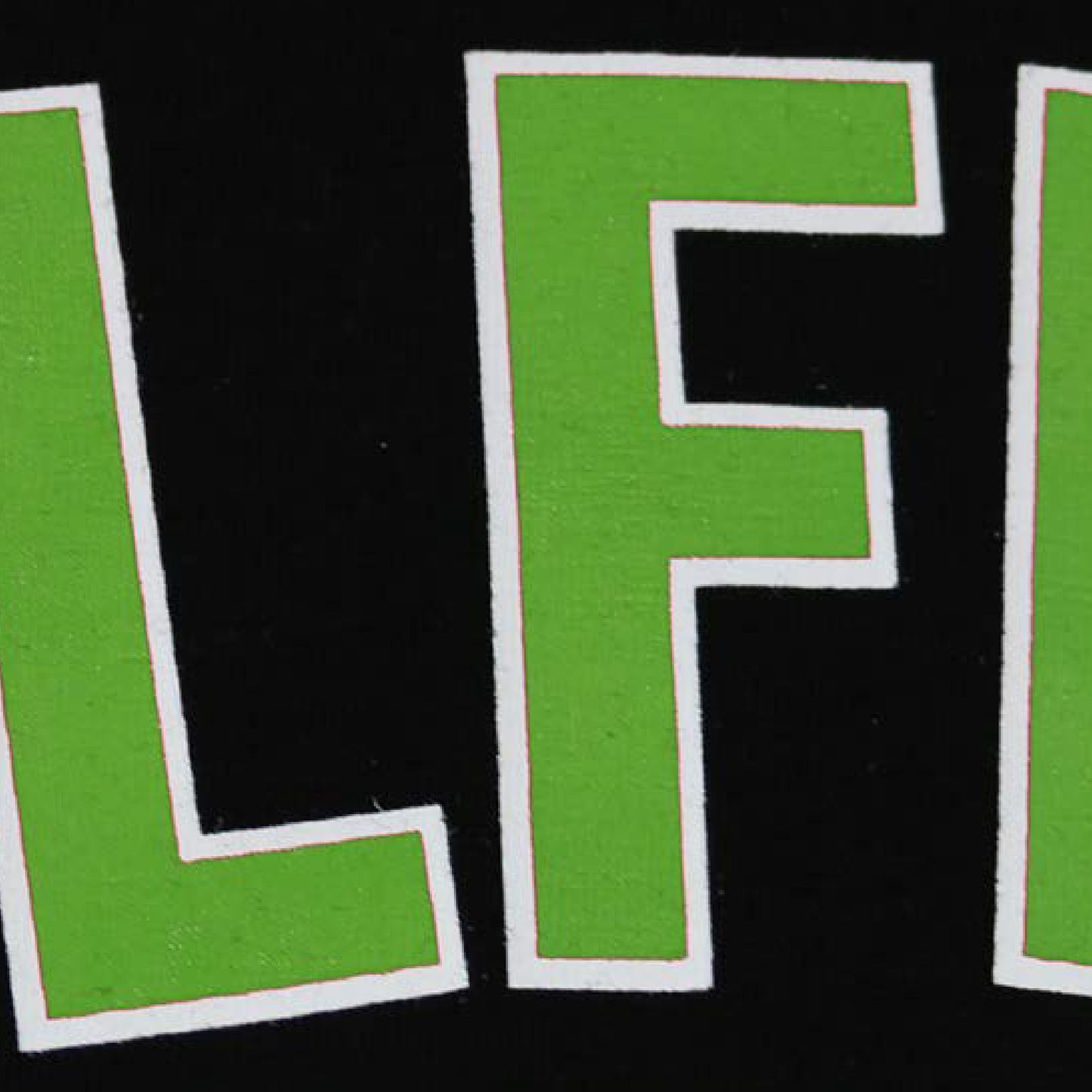

- Enhanced opacity

- Improved cure range

- Excellent bleed resistance

- Low cure, save energy

- Imporved printability

Fabric Types

- 100% polyester, triblends, polyester blends, cotton/poly blends, non-woven polypropylene bags

Mesh

- Counts: 86-230 t/in (34-90 t/cm)

- Tension: 25-35 n/cm

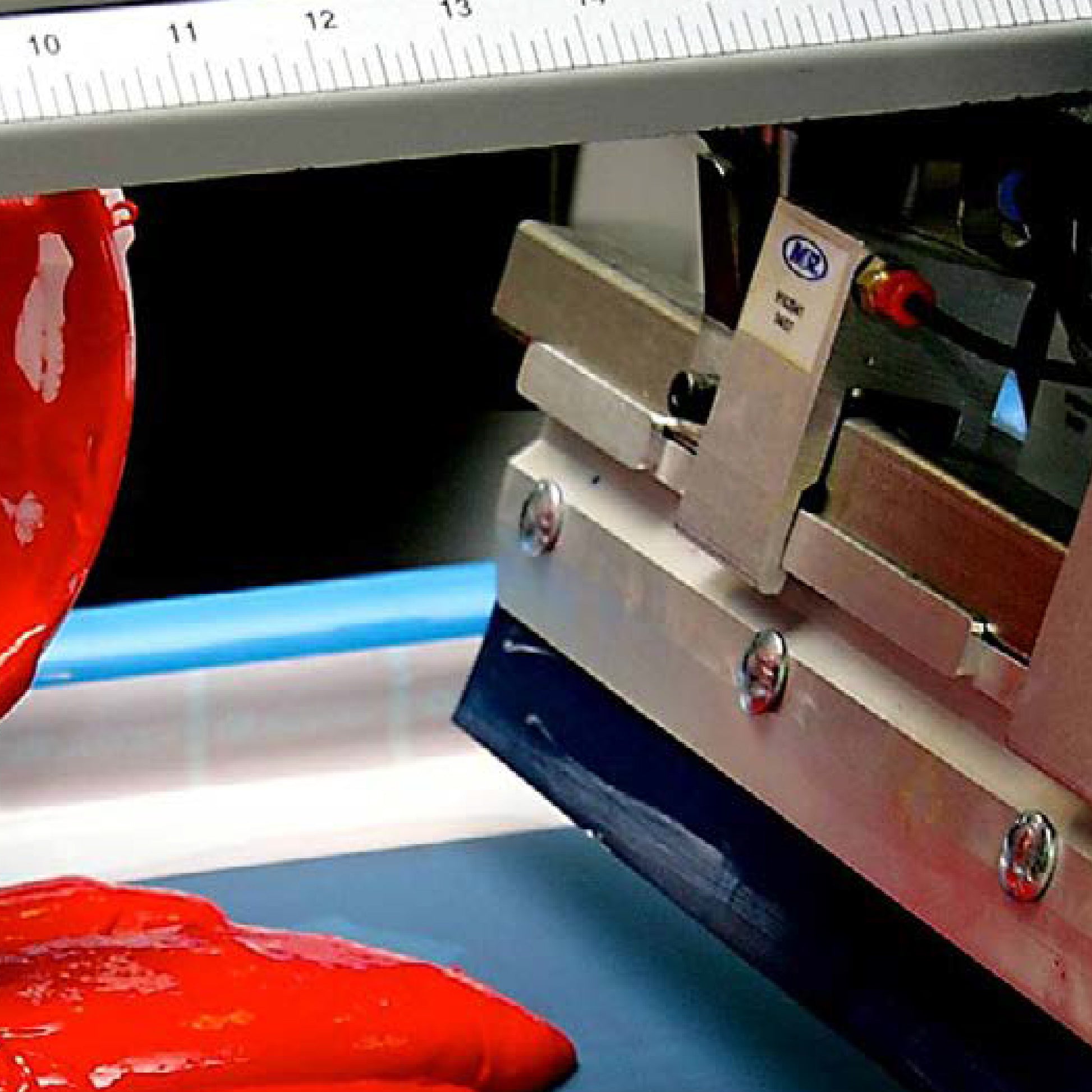

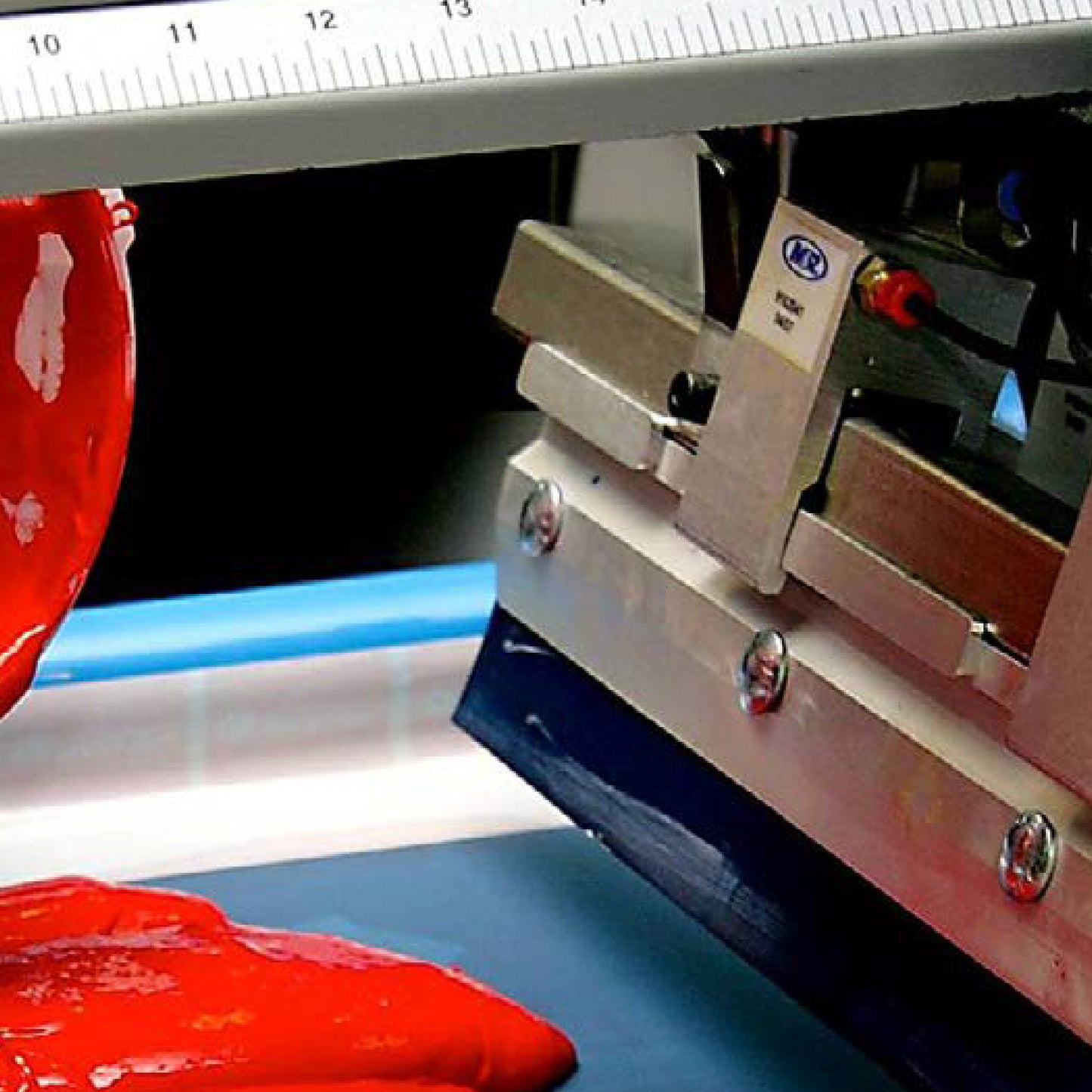

Squeegee

- Durometer: 60/90/60, 70/90/70, 70

- Edge: Square, Sharp

- Stroke: Hard flood, fast stroke

- Angle: 10-15%

Non-Phthalate Stencil

- Direct: 2 over 2

- Off Contact: 1/16” (.2cm)

- Emulsion Over Mesh: 15-20%

Flash & Cure Temperatures

- Flash: 160°F (70°C)

- Cure: 250°F - 300°F(121°C - 148°C) Entire ink film

Pigment Loading

- N/A

Shipping & Storage

- 65-90°F (18-32°C)

- Avoid direct sunlight.

- Use within one year of receipt

Clean Up

- Ink degradant or press wash

- Stir inks before printing

- Use consistent, high-tensioned screen mesh and sharp edged squeegees for best print results

- Use a printing technique to assure a good ink deposit to maximize bleed resistance and film strength properties

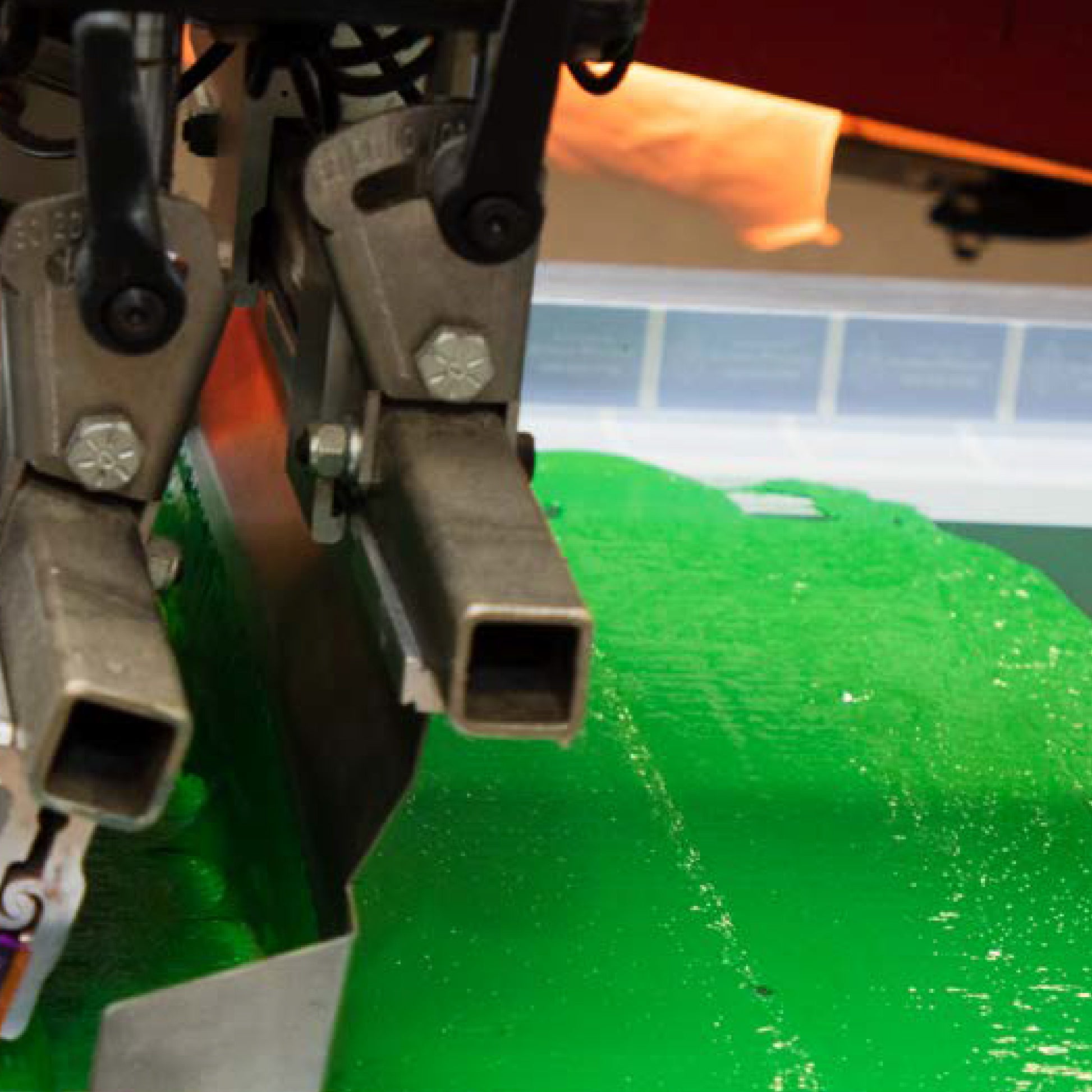

- Rival Sport LC white demonstrates improved printability making it ideal for manual and automatic printing

- Rival Sport LC White is a low bleed ink. For challenging fabrics using sublimation dyes, a bleed blocking underbase such as EPIC Armor LC Gray or Black is required

- Adjust flash cure temperature and dwell time so ink is just dry to touch. Depending on flash unit, a 2-3 second flash is adequate

- Curing is a time and temperature process, a lower oven temperature setting with a slower belt speed while maintaining recommended ink cure temperature is always best to protect fabric, control dye migration and reduce energy consumption

- Rival Sport White can be cured between 250°F - 300°F (121°C - 148°C). Running at the higher end of the temperature range and/or longer dwell times maybe required to achieve proper cure on jobs that contain cotton, high ink deposits or heavy weight garments. Use a setting of 250 on non-stretch, sensitive fabrics, such as polypropylene, Rayon or Denier.

- Suitable for use as an underbase flash white or as a hi-lite white

-

The information above is given in good faith and does not release you from testing inks and fabrics to confirm suitability of substrate and application process to meet your customer standards and specifications