Often Purchased With

-

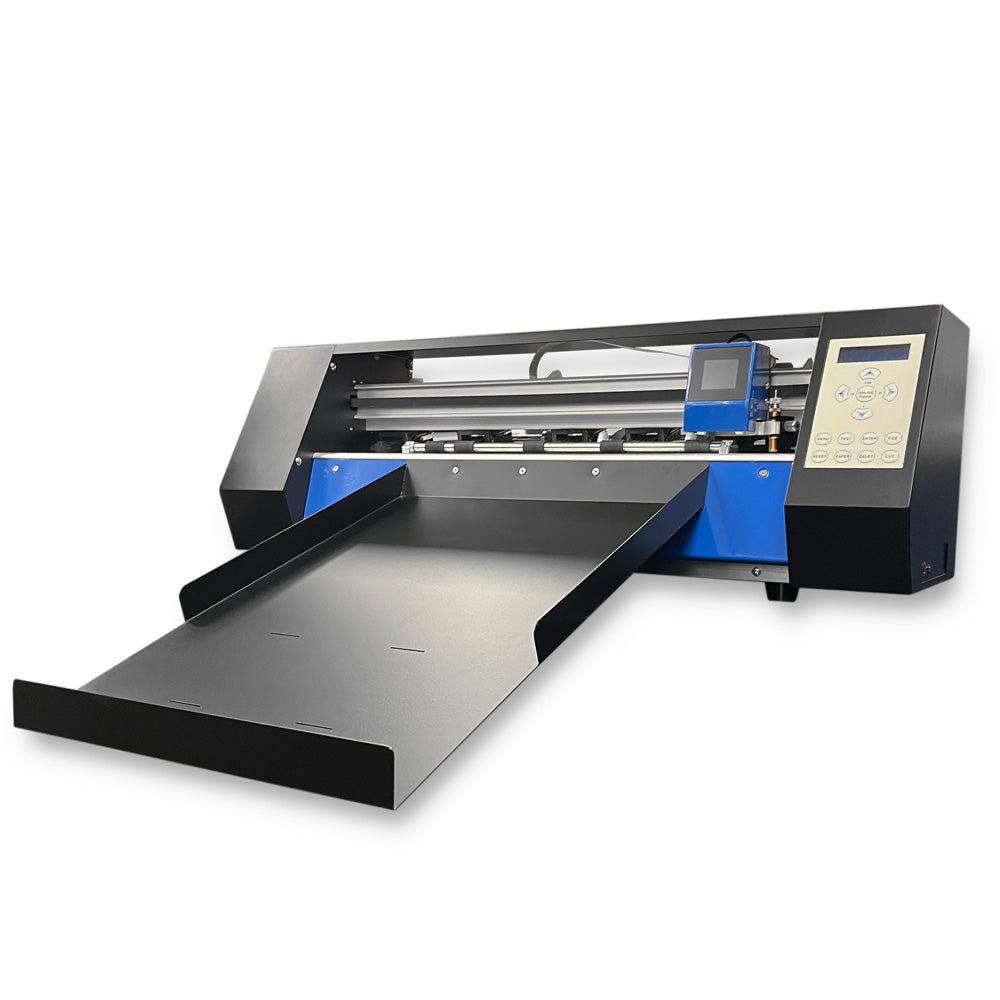

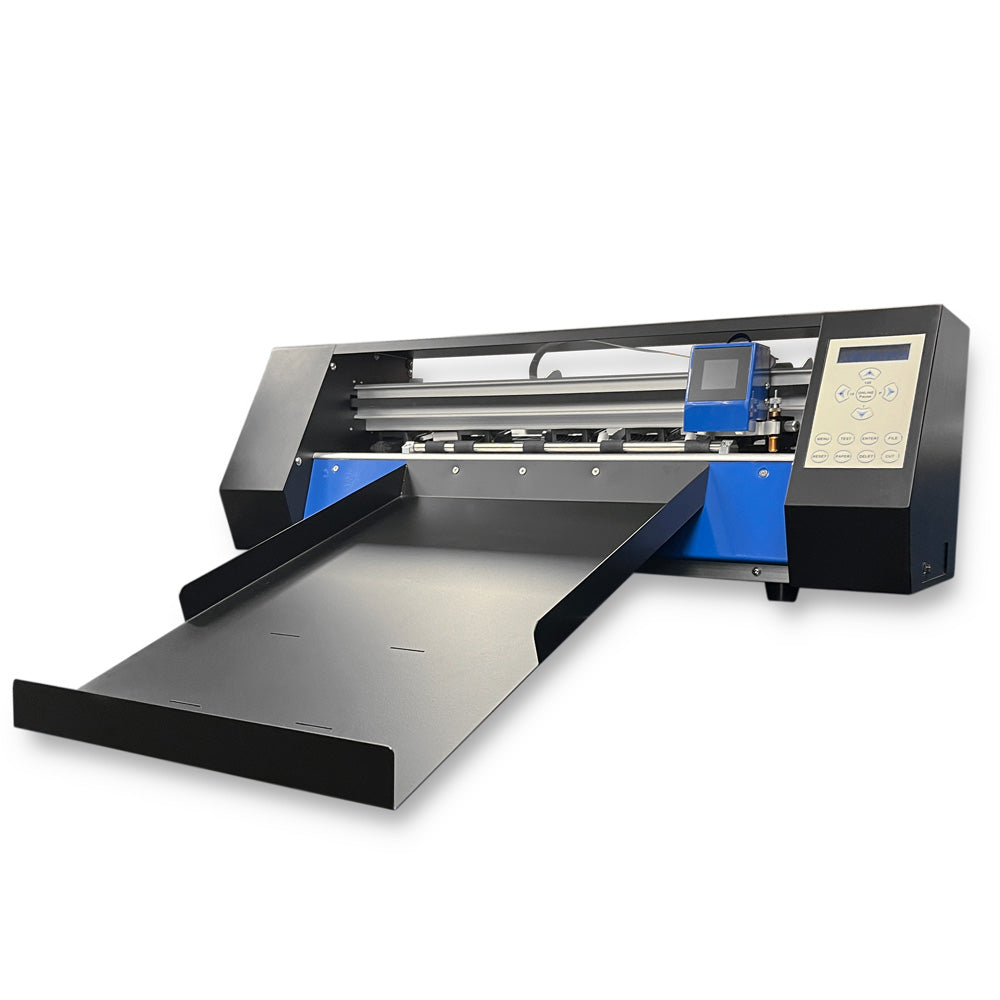

Toyoda Falcon UV DTF Printer

UVDTF-FALCON-1 -

RB Vibra UV DTF Ink

UVDTF-VIBRA-WPrix habituel Du $120.00 CADPrix habituelPrix unitaire par -

RB Vibra UV DTF Clear Varnish

UVDTF-VIBRA-VPrix habituel $110.00 CADPrix habituelPrix unitaire par -

RB Vibra UV DTF Cleaning Solution

UVDTF-VIBRA-CSPrix habituel $45.00 CADPrix habituelPrix unitaire par -

RB Vibra UV DTF Transparent Head Moisturizing Liquid

RB-VIBRA-DTF-TMLPrix habituel $20.00 CADPrix habituelPrix unitaire par -

RB Onyx UV DTF Film (For Roll Printing)

ONYX-UV-R16Prix habituel Du $290.00 CADPrix habituelPrix unitaire par

-

High Resolution Camera Recognition -

Intelligent Deviation Correction Program -

Innovative Double Row Wheel Design

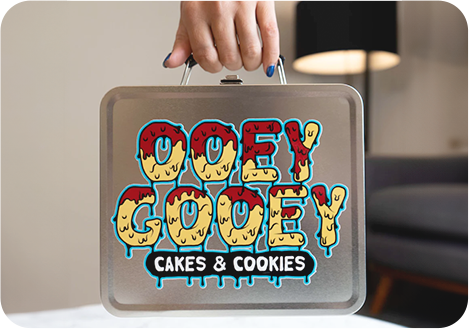

UV Direct-To-Film Applications

-

Plastic -

Wood -

Ceramic -

Glass -

Metal -

Leather

Additional Information

Printing Steps

1. The design is loaded into the software, and optimized for high resolution (300 dpi or better). It includes a transparency layer to ensure seamless integration with any background and crisp edges that guarantee no blushing or blurring occurs on the edges, maintaining the design's sharpness and clarity.

2. The Rip software works seamlessly to separate colors into individual layers and channels, carefully determining the precise amount of ink to allocate to each channel of the print head. This meticulous color separation process ensures accurate color reproduction and vibrant prints that capture every detail.

3. In order to maximize the usable area of the adhesive roll for printing, the software efficiently organizes multiple designs. By strategically arranging the designs, it minimizes waste and maximizes efficiency, resulting in a more cost-effective and streamlined production process.

*Note: If you will be utilizing the Toyoda Falcon Cutter, you are also able to arrange the artwork into 12" artboards so that you can feed these into the cutter and get them automatically cut after printing. These artboards will have registration marks on each corner so that the cutter can detect its parameters and cut to precision.

4. The designs are meticulously printed in layers on the adhesive "A" roll, starting with a solid white base. This base layer acts as a foundation, ensuring that the subsequent colors appear vivid and true to the original design. Each color is carefully applied, ensuring precise registration and vibrant hues. Lastly, a layer of varnish is added, providing a protective and glossy finish that enhances the overall visual appeal.

5. To ensure a secure and durable bond between the ink and adhesive, the printed stickers, decals, or logos are subjected to the power of UV lamps. These lamps emit ultraviolet light that cures the ink almost instantly, penetrating through the varnish and ink layers. This curing process creates a strong and resilient bond, ensuring that the design remains intact even under harsh conditions.

6. In the final step, the finished stickers, decals, or logos pass through an on-board laminator. This process adds an additional layer of protection and durability to the UV DTF transfers, ensuring that they are ready for application and capable of withstanding the test of time.

Cutting Steps

1. If you opted to complete "Step 3" and set up a 12" artboard around your artwork, simply manually cut out these artboards from your printed roll.

2. Load the 12" sheet that you cut on to the top paper tray of the Toyoda Falcon Cutter. The cutter will detect the registration marks around your 12" sheet and cut out each sticker on this sheet into individual squares.

| Model Number | TF-FBCUTTER-24 | |

|---|---|---|

| Interface | The USBU disk has two interfaces | |

| Maximum Feed Width | 13” | |

| Maximum Cutting Width | 12.6“ | |

| Margin Size | Leave 5mm white on each side of the material | |

| Mark | 5mm dot marking/camera recognition | |

| Pages of Material | Can hold 100 sheets of material / 18mm thick | |

| Motherboard | High speed microprocessor with 4Mb cache | |

| Display | 1.7 inch LCD screen | |

| Drive | Digital stepper motor, micro-step drive | |

| Control Panel | Film switch (Life 1,000,000 cycles) | |

| Drawing Instruction | DMPL / HP-GL | |

| Maximum Cutting Speed | 800mm/s | |

| Maximum Cutting Thickness | 1mm | |

| Knife Pressure | 50g ~ 800g (160-grade digital cycle adjustment) | |

| Power Supply | 110V / 2A | |

| Mechanical Accuracy | The 0.025 mm | |

| Repetition Accuracy | + / - 0.1 mm | |

| Net Weight / Gross Weight | 55 lbs / 66 lbs | |

| External Dimensions | 30” (W) x 34” (L) x 11” (H) | |

| Supports Direct Output of CDR | X4 - X8, 2017-2024 | |

| Supports Direct AI Output | CS6-2024 | |

| Supports Windows System | Windows 7 - Windows 11 | |

Is the Toyoda Falcon Cutter for UV DTF Sheets right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Toyoda Falcon Cutter for UV DTF Sheets to your apparel decorating business.