Features And Highlights

-

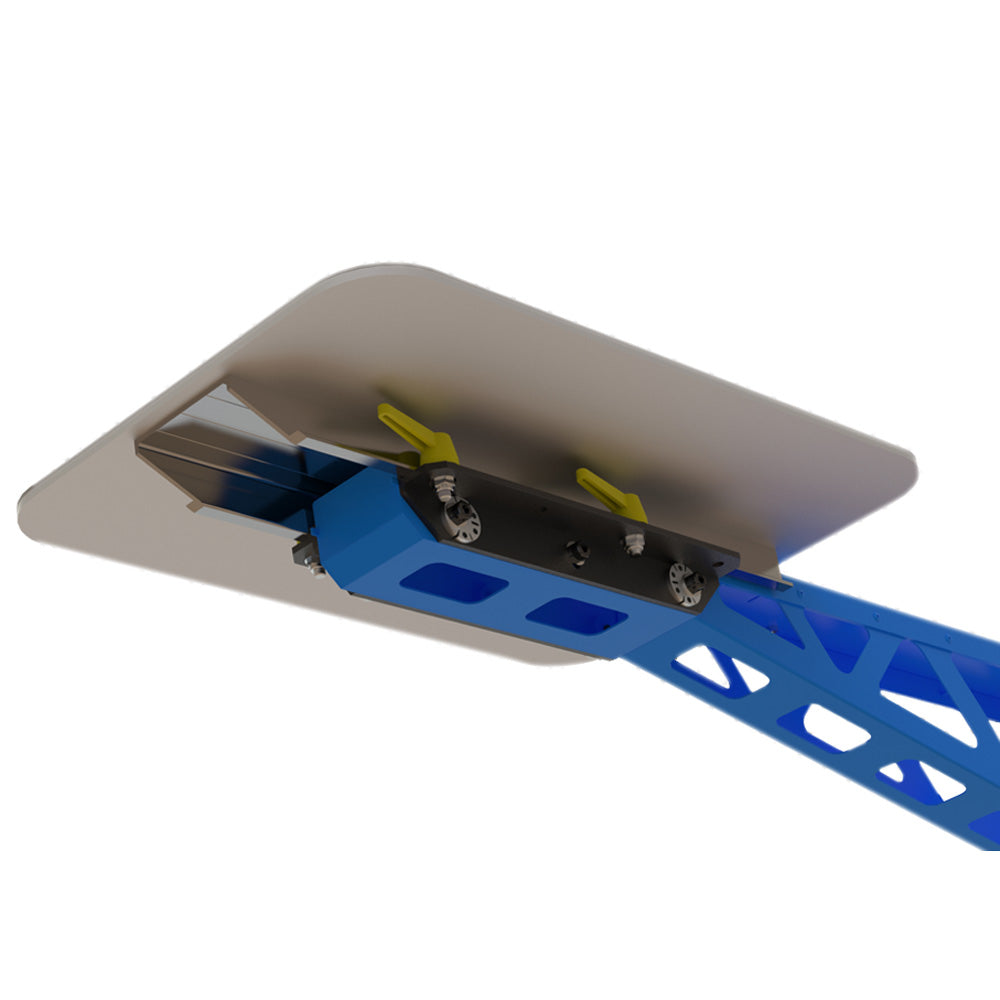

Squeegee Pressure Equalizer System

Revolutionary printhead technology with auto balancing system

-

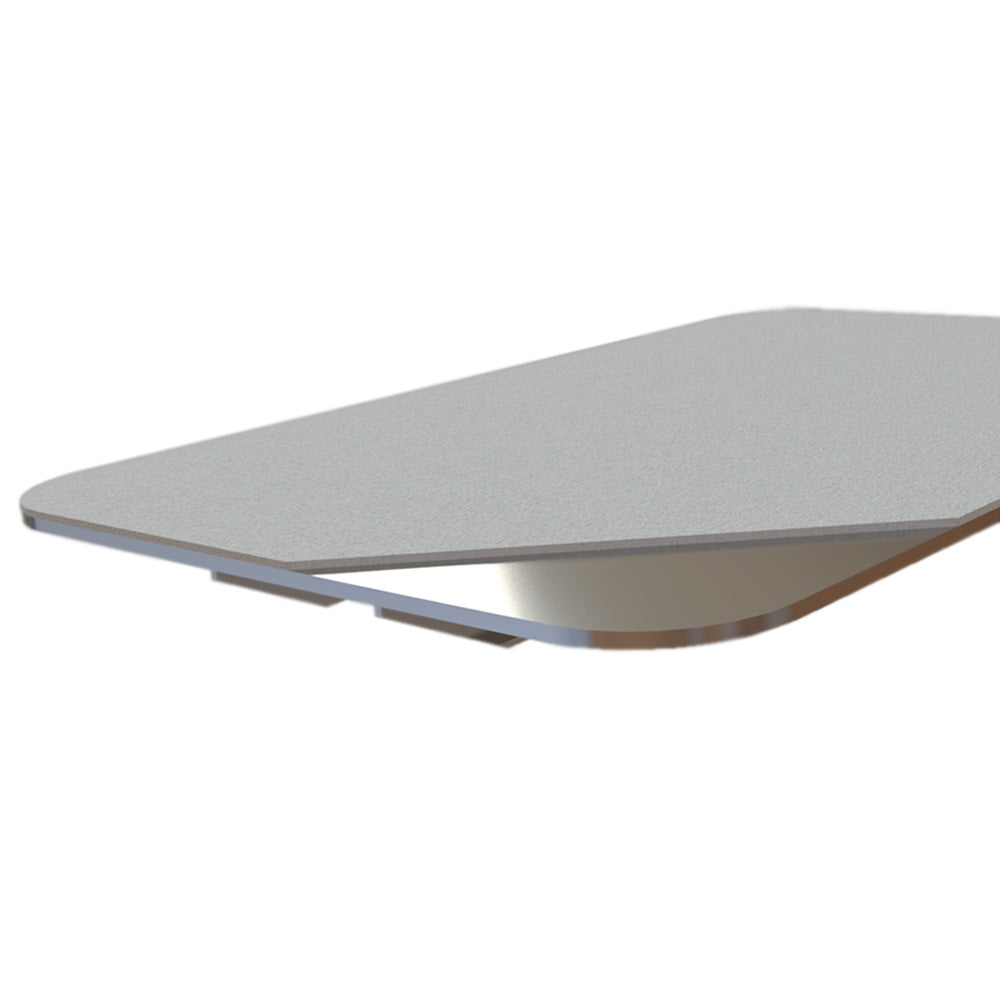

Solid Aluminum Pallet

Insulated special rubber coating to minimize heat loss for better print quality

-

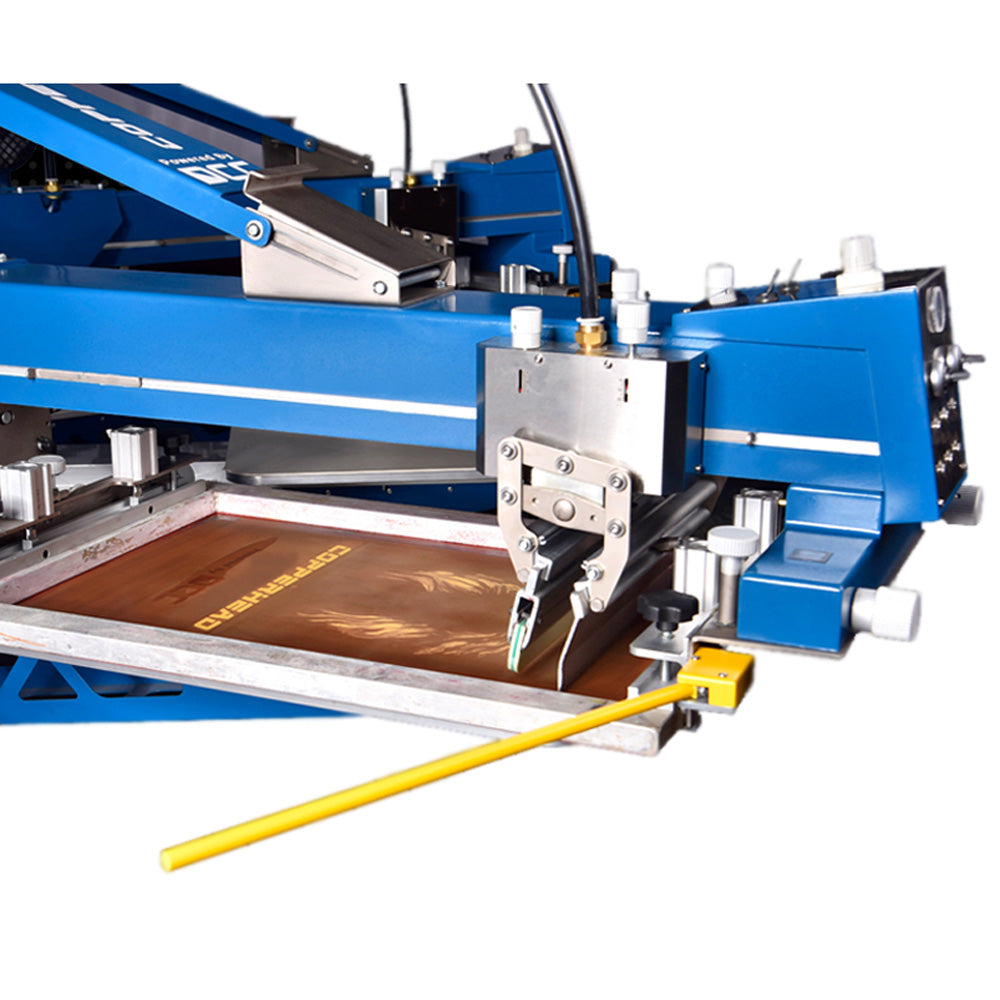

Design & Construction

Heavy-duty welded steel structure

-

Quality Inside And Out

With easy retrogression feature, multiple layers of ink deposited for high definition

-

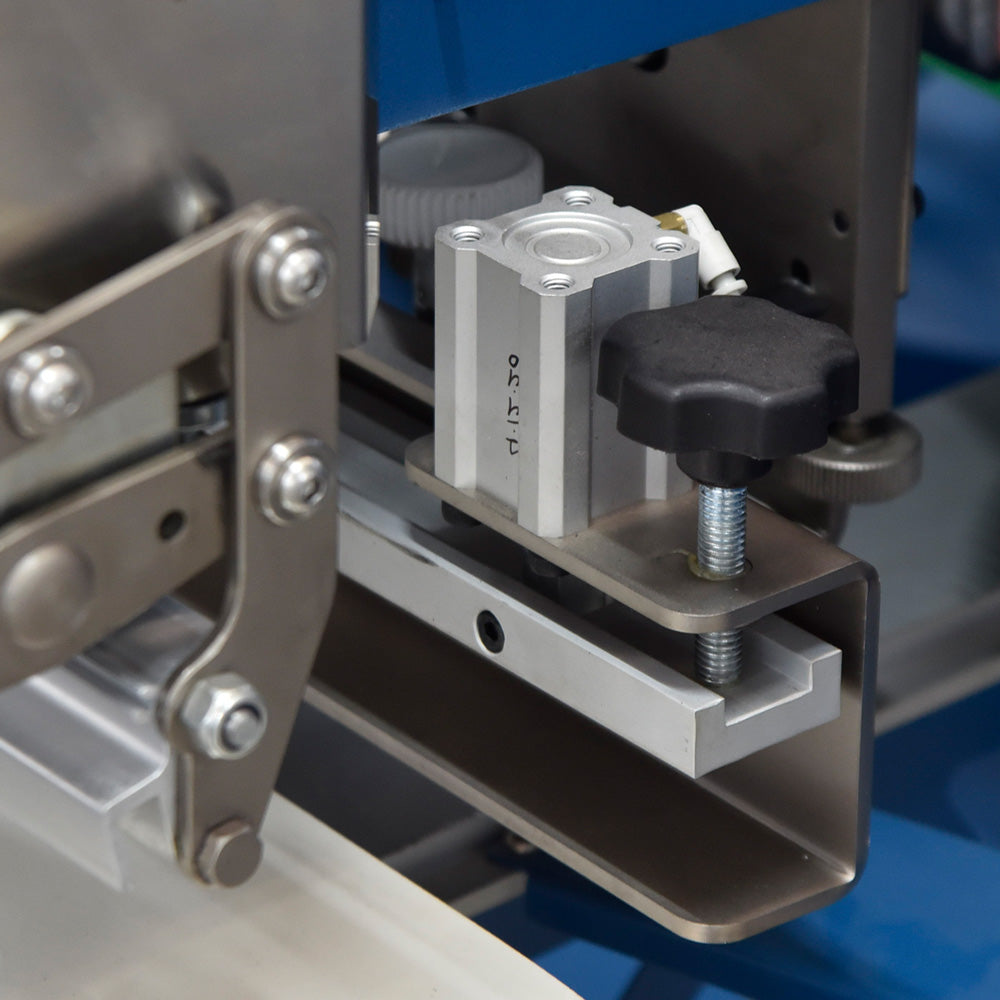

Precision Matters

Innovative indexing mechanism with an accuracy of +/-5 microns

-

Print Stack Mode

Stacks layers of ink for HD & specialty printing

Additional Information

- CAROUSEL/INDEXER SYSTEM

-

- Clockwise or counterclockwise rotation

- CONTROL CENTER

-

-

Icon-based digital touchsreeen control panel

-

Multiple (1-9) print stroke capability

-

Provides control of multi-print functionality

-

Real-time production data

-

Optional foot pedal allows operator to skip printing on a particular pallet

-

Maintenance reminder mode alerts operators when scheduled maintenance is due with pictures & respective procedures

-

Idle Mode to pre heat pallets

-

Independent print-start/print-finish setting automatically activates and stops printheads at the beginning and end of screen printing runs

-

Onboard self-diagnostics

-

Production speed monitor ensures more accurate job cost estimates

-

Built-in flash connector controlled by touch screen display

-

Print stack mode for HD and specialty printing available

-

- DESIGN & CONSTRUCTION

-

-

Test print setting turns individual printheads on/off during test print cycle

-

Printheads and pallet arms provide the stability necessary for exceptional screen print quality

-

Built of heavy-duty steel and premium components

-

- INDEX SYSTEM

-

-

Servo drives combine higher screen printing press speeds with exceptional smoothness, consistency and longevity

-

- LASER LOCATOR SYSTEM

-

- Assists operators in the precise positioning of garments and cut pieces

- OFF-CONTACT

-

- Tool-free four-corner off-contact settings allow fast and accurate screen leveling

- PALLET SYSTEM

-

- Tool free quick release pallet locks

- PALLETS

-

- Lightweight aluminum, rubber-coated screen printing pallets

- PRINTHEADS

-

-

Low maintenance electric drive motors provide exceptionally smooth print strokes

-

Independent print/flood speed controls on each printhead simplify press setup

-

Squeegee print stroke can be set front-to-back or back-to-front

-

Independent print controls on each printhead

-

Multi-print option with or without head lifting

-

- REGISTRATION

-

-

Rear micro-registration

-

Enhanced front micro-registration adjustments with visual guides

-

4 point registration system provide consistent accurate set ups

-

- REVOLVER

-

-

Automatically operates individual printheads in programmed sequence and allows flashing without losing a screen printing position

-

Touchscreen display with simplified programming provides easy setup of the Revolver Sequencing Program

-

- SCREEN CLAMPS & HOLDERS

-

-

Adjustable rear screen holders accommodate a wide variety of screen sizes

-

Pneumatic clamps hold frames tight and allow for rapid screen loading. Manual safety knobs save registration in the event of pneumatic air loss

-

Clamping system holds roller frames without special adapters

-

- SQUEEGEE HOLDER

-

-

Squeegee holder can be quickly installed with a locking pin

-

Helps prevent thinner water-based and discharge inks from flowing into the image area

-

- SQUEEGEE/FLOODBAR

-

-

Angle and calibrated pressure adjustments are independently set

-

Independent squeegee & floodbar speed adjustments

-

Visual reference marks every 5 degrees simplify squeegee/floodbar angle adjustments

-

Front or rear print carriage stop position allows operator to leave screens clear or flooded (great for water-based inks)

-

Squeegee pressure regulator on each printhead offers exceptional control of print pressure

-

- STROKE LENGTH ADJUSTMENT

-

-

Tool-free stroke length adjustment maximizes screen printing speed

-

- WARRANTY, SERVICE AND SUPPORT

-

- 24-hour hotline is staffed 365 days a year

- Access to M&R’s Training Center

- Two-year limited warranty

| SPECIFICATIONS | ICON 5671 20/6 | ICON 5671 26/8 | ICON 5671 32/10 | ICON 5671 38/12 | ICON 5671 44/14 | ICON 5671 50/16 | ICON 5671 56/18 | ICON 5671 62/20 |

| Air @ 7 Bar (102 psi) | 1100 l/min (39 cfm) | 1430 l/min (51 cfm) | 1760 l/min (62 cfm) | 2090 l/min (74 cfm) | 2420 l/min (86 cfm) | 2750 l/min (97 cfm) | 3080 l/min (109 cfm) | 3410 l/min (120 cfm) |

| Electrical Requirements1 | 208-230 V, 3 ph, 13 A, 50/60 Hz, 4kW (UL) 380-415 V, 3 ph, 11.5 A, 50 Hz, 4kW (CE) |

208-230 V, 3 ph, 15 A, 50/60 Hz, 4.75kW (UL) 380-415 V, 3 ph, 11.5 A, 50 Hz, 4.75kW (CE) |

208-230 V, 3 ph, 17.5 A, 50/60 Hz, 5.5kW (UL) 380-415 V, 3 ph, 12.5 A, 50 Hz, 5.5kW (CE) |

208-230 V, 3 ph, 20 A, 50/60 Hz, 6.25kW (UL) 380-415 V, 3 ph, 16.5 A, 50 Hz, 6.25kW (CE) |

208-230 V, 3 ph, 22 A, 50/60 Hz, 7kW (UL) 380-415 V, 3 ph, 16.5 A, 50 Hz, 7kW (CE) |

208-230 V, 3 ph, 24.5 A, 50/60 Hz, 7.75kW (UL) 380-415 V, 3 ph, 16.5 A, 50 Hz, 7.75kW (CE) |

208-230 V, 3 ph, 27 A, 50/60 Hz, 8.5kW (UL) 380-415 V, 3 ph, 21 A, 50 Hz, 8.5kW (CE) |

208-230 V, 3 ph, 29.5 A, 50/60 Hz, 9.25kW (UL) 380-415 V, 3 ph, 21 A, 50 Hz, 9.25kW (CE) |

| Maximum Built-in Flash Cure Unit Plugs |

6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Standard Image Size | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") | 56 x 71 cm (22" x 28") |

| Standard Pallet Size | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") | 60 x 89 cm (23.5" x 35") |

| Standard Frame Size (OD) | 71 x 109 cm (28" x 43") | 71 x 109 cm (28" x 43") | 71 x 109 cm (28" x 43") | 71 x 109 cm (28" x 43") | 71 x 109 cm (28" x 43") | 71 x 109 cm (28" x 43") | 56 x 71 cm (22" x 28") | 71 x 109 cm (28" x 43") |

| Overall Size (L x W x H) | 864 x 358 x 209 cm (340" x 141" x 82.3") |

1087 x 358 x 209 cm (428" x 141" x 82") | 1311 x 358 x 209 cm (516" x 141" x 82.3") |

1535 x 358 x 209 cm (604" x 141" x 82") | 1758 x 358 x 209 cm (692.3" x 141" x 82.3") |

1982 x 358 x 209 cm (780" x 141" x 82") | 2206 x 358 x 209 cm (868.5" x 141" x 82.3") |

2431 x 358 x 209 cm (957" x 141" x 82") |

| Stations/Colors | 20/6 | 26/8 | 32/10 | 38/12 | 44/14 | 50/16 | 56/18 | 62/20 |

| 1Use uninterruptible power supply (UPS) to safeguard machine from voltage fluctuation out of main supply. If incoming voltage differs from the voltage(s) listed in the brochure, calculate amperage accordingly. Contact M&R Global/ your nearest dealer for total amperage in case of using built-in flash sockets. | ||||||||

Is the Presse à sérigraphie manuelle M&R Kruzer right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Presse à sérigraphie manuelle M&R Kruzer to your apparel decorating business.