Features

-

Drag-N-PlayAn exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage of the laser engraver to the desired position to be engraved and press the start button to commence the job.

-

Innovative Windows DriverDirectly output from familiar designing software like Illustrator, CorelDraw, AutoCad through GCC LaserPro Windows driver for laser engravers. The innovative driver features SmartCENTER, Air Assist by Pen, Defous by Pen, Bridge Cutting, Drill, Dithering Patterns, and more to reduce set up time and make easy adjustments to achieve marvelous output quality.

-

Built-In Networking ConnectionNetwork connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using network connection. Free your designers with great flexibility and maximum machine versatility.

-

Key Switch & Emergency StopKey switch safeguards the laser engraver from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

-

SmartCENTER™ (Patented)The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

-

Astonish 3D EngravingGCC LaserPro integrates laser firing control and image processing technology to create a 3D laser engraving function, the laser system assigns up to different laser powers to 200 levels of grayscale in the image to make the spectacular 3D effects with different slopes.

-

TrueImage™ Engraving Technology (Patented)The patented TrueImage function employs a uniquely designed laser firing algorithm that presents its most vivid form when laser engraving images.

-

SmartACT™ (Patented)Spirit GLS Hybrid laser engraver SmartACT™ is a groundbreaking technology that reduces the ramping process and job running time for laser engraving, which translates into higher productivity.

-

RoHS ComplianceAll GCC laser engravers are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide eco-friendly products to protect the earth for our further generations.

-

SmartPIN™ AutoFocus (Patented)The plug-and-play probe design makes focusing a one-touch process and provides the accuracy and precision required for optimum quality even when laser engraving on transparent materials.

-

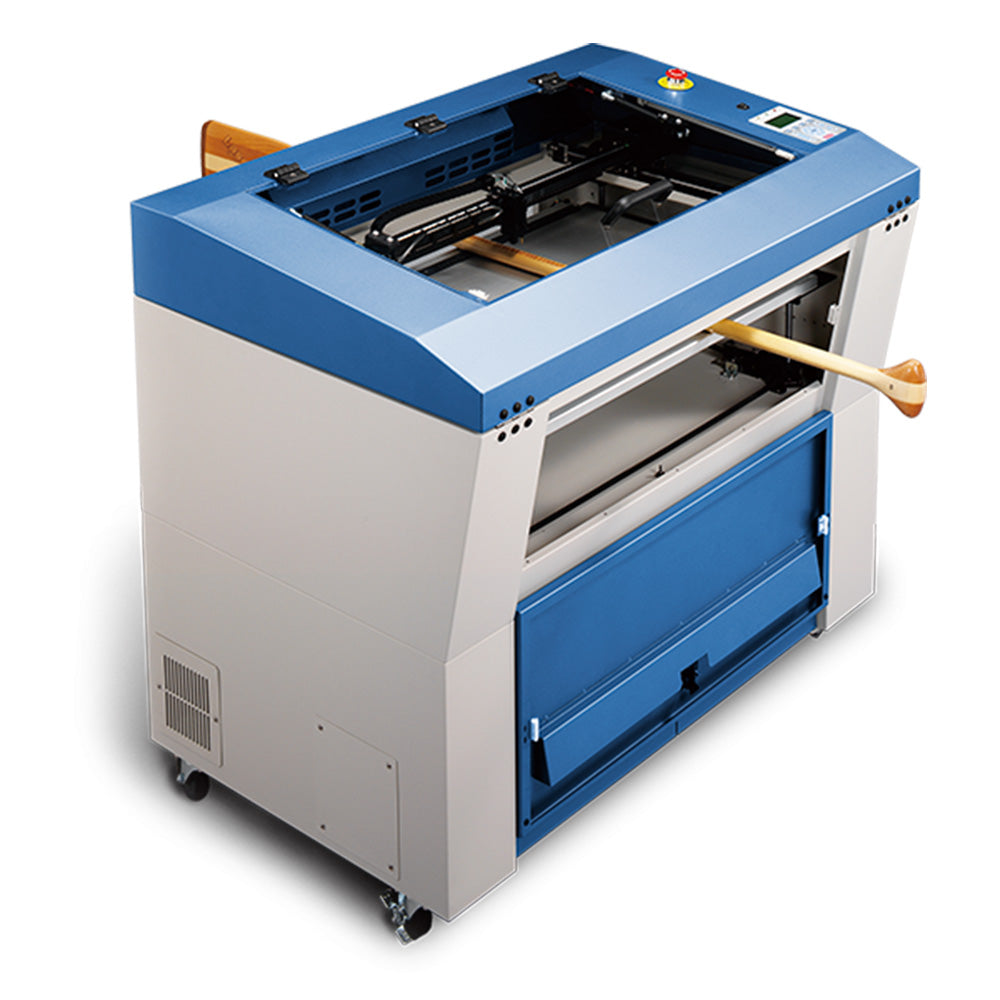

Pass-through Front to Rear Doors (Optional)A design with doors on both ends of the laser engraver to accommodate extremely long working pieces without the need for a screwdriver.

-

DuraGuide Motion DesignSystematic and reliable motion system embedded with strong mechanical framework and accurate servo motor control technology to deliver superb laser engraving output quality under rapid movement.

-

SmartLIGHTA Built-in LED light module illuminates the working space of the laser engraver and makes every laser engraving detail easy to see.

-

Intuitive Control Panel InterfaceA control panel with coherent hot-key design and graphical icon displays that allows you to change laser parameter settings, set jobs to repeat unlimited times, queue jobs, delete jobs, and more.

-

Rigid and Reliable ConstructionRigid and stable chassis construction of the laser engraver ensures consistent output quality under high speed movement.

-

Programmable Origin ModesEasy-to-use multiple position modes allow the operators an effortless way to set up laser engraving jobs with Drag-N- Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location.

-

SmartLID™ (Patented)An innovative lid that opens from both ends of the laser engraver allows easy access for daily maintenance.

-

Closed-loop DC Servo Technology (Patented)Spirit GLS Hybrid laser engraver utilizes Closed-loop DC servo motor that delivers greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy for laser engraving due to the continuous movement, instead of constant stopping and starting.

-

Bridge CuttingBridge Cutting function diversifies the laser cutting into packaging prototyping and fulfill versatile requirements. Define the cutting gap to create the dashed line effect from user friendly print driver interface.

Application Ideas

-

Wood -

Twill Cutting -

Metal -

Leather -

Glass -

MDF Boards -

Cardboard Packages -

Foam Inserts

Additional Information

-

Flame Sprinkler SystemLaser engraving and cutting operations using the flame sprinkler system protects the operator, machine, and working objects from potential fire hazards. During the engraving process, flaming may occur when working with combustible or easily-flammable materials, such as paper or wood. The flame sprinkler system is an optional item that automatically ejects gas to extinguish flames when they reach 68°C/155°F moments after the onset of the fire.

-

AAS Contour Cutting DeviceDeveloped by GCC LaserPro, AAS is an exceptionally user-friendly operation which offers accurate and faultless contour cutting by automatically tracking the position of graphics for laser engravers and cutters.

Note: Working area and engraving speed will be reduced when AAS module is installed.

*The working area will be changed to 530mm X 420mm (20.8" x 16.5") after installing the AAS Contour Cutting Device. -

SmartVISION™ Pro CCDThe GCC LaserPro laser engraver features the CCD module, which significantly boosts productivity by learning, memorizing, and precisely locating printed graphics. This allows for contour cutting, automatically adjusting the settings to ensure accurate cuts on various materials. By installing the SmartVISION™ Pro CCD, the working area can be exchanged to 770 mm x 595 mm (30.3" x 23.4").

Please note that the SmartVISION Pro CCD is exclusively compatible with CO2 single models. -

Dust Prevention WindowWhen the laser system is on duty, it will bring a lot of dust result from the material and it will contaminate the lenses and mirrors. Dust Prevention Window can keep lenses and mirrors clean to promote longer laser life and increase the effect of air induction.

-

SmartAIR™ Fine NozzleThe optional SmartAIR Fine Nozzle is recommended for laser engraving or cutting thin materials such as textile. The smaller caliber nozzle is positioned closer to the object for a concentrated blast directed over a small area to eliminate burning on the cutting edge. The perfectly-vertical design of the SmartAIR Fine Nozzle produces a concentrated airflow to blow away dust and unwanted residue, leaving a clean product surface.

-

Roll to Roll AutofeederThe Roll to Roll Autofeeder unit is a great optional item that can be used in tandem with Spirit or Spirit LS, or Spirit GLS model to form an automated engraving system when working with rolled material. For instance, if used with Heat transferable materials, the laser can produce very fine and delicate patterns which can be heat pressed directly without the need for weeding. This is an essential solution to mass production requirements.

* The width of material loading is limited to 600 mm (23.6”) -

SmartBOX™An innovative technology for laser engravers and cutters that integrates the ventilation box with a honeycomb table or aluminum grid cutting table. The result is not only a precise cut with sharp edges, but also a clean laser table to work on.

-

External Interface Control BoardThe External Control Interface Board is an optional item that allows users to set up GCC LaserPro laser engraving and cutting systems for communication with external devices such as odor reduction units, robot arms, and others via a 5V or 12V signal to form an automatic production line. Another useful practice applies in certain working environments when users are required to set up an extra remote interlock control or when laser machines are allowed to be switched off if a security device is triggered.

-

Grid Cutting TableThe grid cutting table is an ideal pal for laser cutting. It lifts the work piece off the work table from hitting by laser reflection while supports it with reinforced grid design. The dust and vapor created during laser cutting are then taken away effectively through the grid by down vacuum funnel exhaust. Rather than handling rigid materials, grid cutting table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting result.

-

Entry-Level Fume Extraction SystemGCC PA-1500FS & PA-1000FS, CE-certified fume extraction systems, are designed to remove hazardous fumes and dust during laser processing to protect the health of operators, eliminate environmental pollution and enhance laser engraving and cutting.

* For seamless fume extractor control via laser machines, we recommend considering the purchase of an external I/O board. -

Wi-Fi RouterWi-Fi router allows you to transmit data through a wireless network. It can work with GCC laser engravers and RX II/ Jaguar V cutting plotters through the Ethernet port (not applicable for Japanese users.) Whether you are sending files to multiple GCC machines using one PC or sharing one unit of GCC machines with multiple PCs, this wireless technology can be an excellent helper.

-

SmartPRINT™SmartPRINT™ software features powerful functions, an intuitive interface, and built-in GCC LaserPro laser parameter setting for both Mac and Windows users. SmartPRINT™ provides clipart libraries, compatibility for various file formats, and advanced graphic functions such as Auto Trace Image Contour, Convert to Rhinestone, Generate Puzzle, and many more. Also, the additional text justification and sizing options can convert stroke to the path.

-

Honeycomb TableA clean and better cutting quality is achieved by the honeycomb table when cutting materials into small pieces. It lifts the workpiece off the work table from hitting by laser reflection. The dust and vapor created during processing are then taken away effectively through the honeycomb cell by a down vacuum funnel exhaust. Rather than handling rigid materials, the honeycomb table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting results.

-

SmartGUARD™ Fire Alarm (Patented)Laser engraving and cutting operation using the SmartGUARD Fire Alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut-down the operation system immediately.

-

Air CompressorA specially designed Air Compressor, by using an oil-less diaphragm, helps you eliminate the harmful and damaging side effects of moisture on the laser optics. In addition, it provides the optimal air pressure when laser engraving and cutting to blow away vaporized particles and prevent overheating, keeping lenses and mirrors clean for longer laser life.

-

Purex Fume Extraction SystemGCC teams up with a UK company to offer the Purex fume extraction unit for its full-line GCC LaserPro laser engraving and cutting systems. Purex is specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Noise-free operation, high vacuum capacity, compact design, and long life expectancy, the Purex is CE-compliant that represents the latest invention in exhaust extraction and smoke reduction technology for all types of applications.

-

Rotary AttachmentElevate the laser engraver and cutter to a higher level! By using the rotary attachment, laser engraving on cylindrical or round objects is now possible. This option uses the fourth axis to rotate your object 360° to allow engraving on cups, wine glasses or even a baseball with two types of conical fixtures available. The minimum/maximum diameter and length of the working object are 7 mm / 150 mm and 650 mm respectively. Its maximum weight should not exceed 4kgs.

-

Rotary ChuckThe rotary chuck for GCC LaserPro Spirit series and S400 is a handy tool used for laser engraving on cylindrical or spherical objects. In addition to the standard X, Y, Z axis, the rotary chuck allows for the fourth axis which rotates the object 360° to allow for engraving on cups, wine glasses, and even spherical objects. The diameter range of the to-be-engraved object is 0.5 mm to 120 mm and the max. length of the object is 410 mm. Its maximum weight should not exceed 4 kgs.

-

Stack Light SetThe indicator will flash to signal the end of job process and is ideal for working environment where audibility is weak. Red light stands for “Error”; Green light stands for “ Stand-by”; Yellow light stands for “Machine is working / Insert the pass-through door key”

(This item is available for machine with 5272 V3 Mainboard and afterwards)

| Spirit LS | |||

|---|---|---|---|

| Work Area | 640 x 460 mm (25 x 18 in.) Extendable to 740 x 460 mm (29 x 18 in.) | ||

|

Max. Part Size (L x W x H) |

All Doors Closed | 762 x 482.6 x 165 mm (30 x 19 x 6.5 in.) | |

| All Doors Open | 762 x ∞ x 165 mm (39 x ∞ x 6.5 in.) | ||

| Table Size | 790 x 530 mm (31.1 x 20.9 in.) | ||

| Dimensions | 1125 x 720 x 1005 mm (44.3 x 28.3 x 39.6 in.) | ||

| Laser Source | 12 to 100W 10.6-μm sealed CO2 Laser / 20W & 60W 9.3-μm sealed CO2 Laser | ||

| Cooling | Air-cooled, Operating environment temperature 15°-30°C (60°-86°F) | ||

| Drive | Closed-loop DC servo control | ||

| Maximum Motor Speed | 80 IPS** | ||

| Speed Control | Adjustable from 0.1-100% (Up to 16 color-linked speed settings per job) | ||

| Power Control | Adjustable from 0-100% (Up to 16 color-linked power settings per job) | ||

| Engraving Capability | 256-level gray scale image processing capability | ||

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | ||

| Z-Axis Movement | Automatic | ||

| Focus Lens | Standard 2.0", optional 1.5", 2.5", & 4.0" available | ||

| Resolution (DPI) | Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 | ||

| Computer Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

||

| Compatible Operating Systems | MS Windows | ||

| Display Panel | 4-line LCD : panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus |

||

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

||

| Facility Requirements | |||

| Operation Voltage | Laser below 80Watt, 100-240VAC, 50-60Hz Auto Switching, Max. 15A Laser 80Watt and above, 200-240VAC, 50-60Hz, Max. 15A |

||

| Fume Extraction System | External exhaust system with minimum flow rate 640m3/h (CFM 377 ft3/min) is required,2.3kPA negative pressure (Pure-Air PA-1000FS @ 4" exhaust port) | ||

|

*Throughput value represents the Max. number of 8 in. x 10 in. 500DPI raster jobs that can be done per hour. |

|||

Is the GCC LaserPro - Spirit GLS right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the GCC LaserPro - Spirit GLS to your apparel decorating business.