Often Purchased With

-

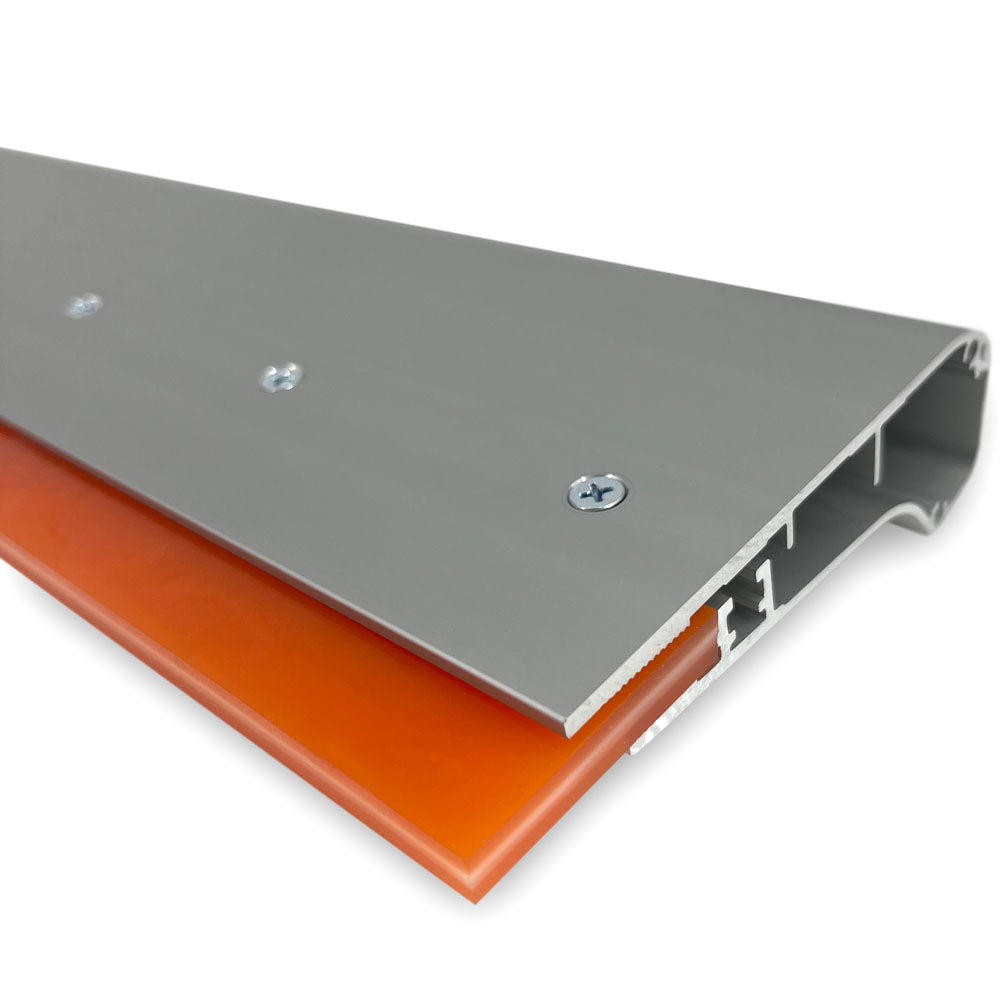

Ergo-Force Squeegee Handle & Blade

EFSH4Prix habituel Du $18.00 CADPrix habituelPrix unitaire par -

Support de raclette de table ultime

TTSRPrix habituel $65.00 CADPrix habituelPrix unitaire par -

Nettoyage à la raclette - Boîte principale

SQCLNBOXPrix habituel Du $1,250.00 CADPrix habituelPrix unitaire par -

Nettoyeur de raclette standard

CL10Prix habituel Du $21.00 CADPrix habituelPrix unitaire par -

Nettoyeur à double raclette

DSSQCLPrix habituel $42.00 CADPrix habituelPrix unitaire par -

EDF 100 - Unité de filtre de vidange 12" x 24" x 12"

RBE-32WPrix habituel $2,995.00 CADPrix habituelPrix unitaire par -

Floodbar Ailé 16"

MRFBW16Prix habituel $155.00 CADPrix habituelPrix unitaire par

Additional Information

What is durometer? Durometer measures the hardness of the squeegee blade. Some squeegees are harder where as some feel softer. Specific print jobs require harder or softer blades. The durometer or hardness level directly indicates how thick or thin an ink deposit can be. Softer squeegees will leave a thicker ink deposit, while harder squeegees will leave a thinner deposit of ink.

- 80 durometer is hard and leaves a minimal ink deposit. Its best for designs going through higher mesh counts with lots of complex details or fine halftones where a thin ink deposit is needed for design clarity.

- 70 durometer is by far the most popular and versatile in the garment industry. It’s a great, general purpose blade for everything from spot colors to halftones. Majority of printers use the 70 durometer as their first squeegee blade.

- 60 durometer is one of the softest blades available. It allows for a thicker ink deposit through lower mesh counts. The durometer is ideal for special effects like puff, glitters, shimmers, and high density applications.

- 60/90/60 triple durometer gives you the benefits of the 60 durometer blade edge, allowing for a good deposit of ink. With the 90 durometer spine, it allows for greater pressure to be applied during printing with minimal squeegee blade deflection. This squeegee blade allows for more ink to be laid down compared to an 80 duro blade.

- 70/90/70 triple durometer gives you the benefits of the 70 durometer blade edge, allowing for a good deposit of ink. With the 90 durometer spine, it allows for greater pressure to be applied during printing with minimal squeegee blade deflection. This squeegee blade allows for more ink to be laid down compared to an 80 duro blade.

Achieving the best screen printing performance from a blade is dependent on the selection of the correct squeegee for the job and proper squeegee maintenance. Squeegee blades need to remain sharp for optimal print quality. When printing, try to keep track of how often the squeegee is used. Over time you will see that a sharp squeegee edge will start to round off due to the abrasion of printing. A rounded squeegee edge will not cut the ink. It will start to hydroplane or glide over the ink, leaving an uneven ink deposit.

The squeegee should always be wiped clean and dried once you're done printing. Ideally, the blade should be allowed to recover from the ink and chemicals for 24 hours before going back into production. Having a few squeegees for your most used durometers in your shop is helpful so you can rotate through them.