Additional Information

While our internal colour-matching allows us to be very accurate, there are several factors which affect the outcome of the colour when it is finally printed onto a garment. The following factors can cause deviation:

Fabric Colour (black, white, gray, color)

- While Monarch inks are high in opacity, fabric colour does create some deviation in colour matching.

Screen Mesh Count (110, 156, 230)

- The amount of ink making it onto the fabric will cause deviation in many colours.

Number Of Strokes (2-pass, print-flash-print, single pass)

- The amount of ink making it onto the fabric will cause deviation in many colours.

Under Base (white under base, gray under base, no under base)

- A white under base will tend to provide the most accurate colour representation, but gray or no under base can cause deviation in colour when printed.

Emulsion Thickness (2 x 1, 1 x 1, 2 x 2)

- Different emulsion thicknesses result in different film weights of the ink on the t-shirt. Film weight differences can cause deviations in PMS colours.

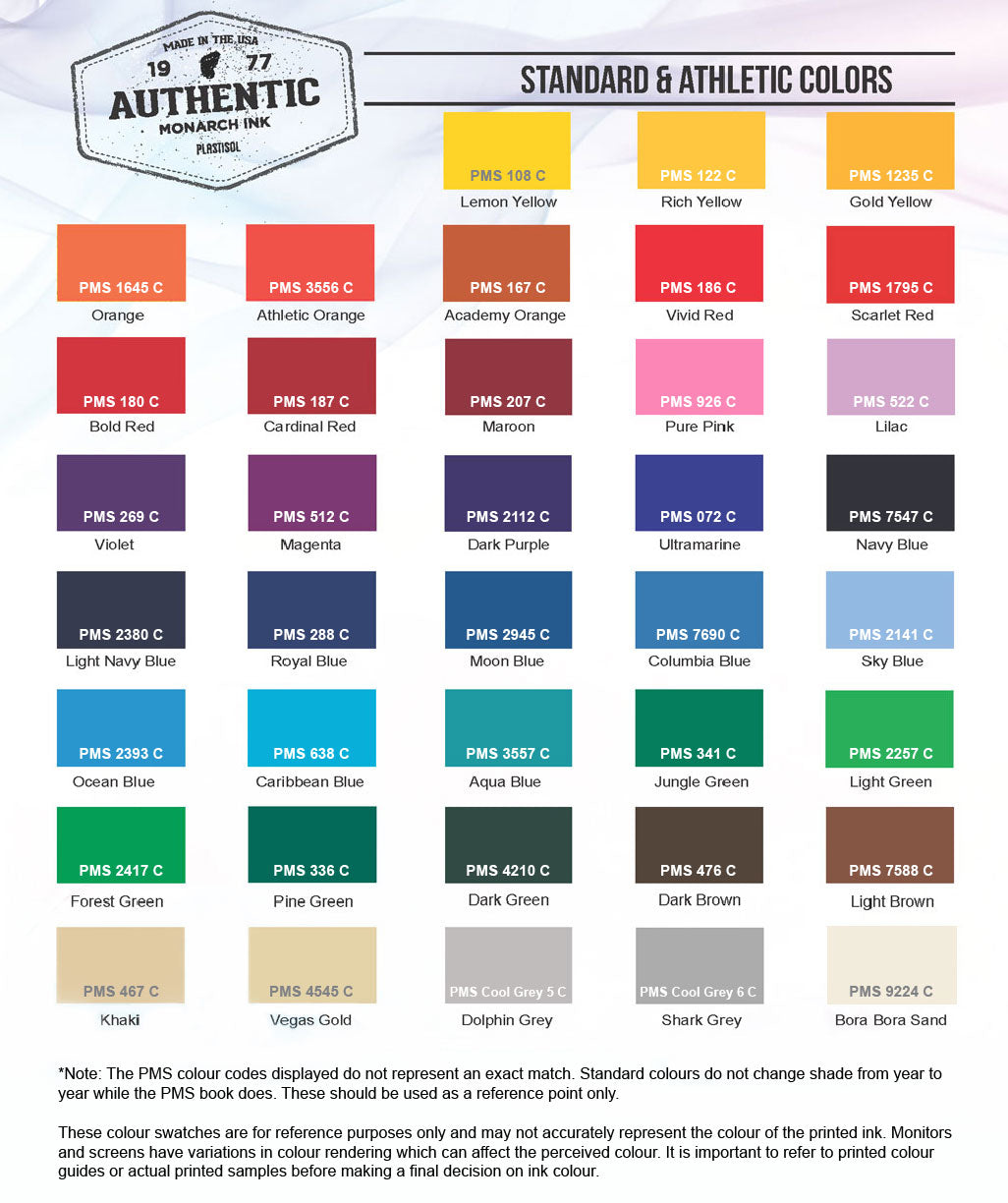

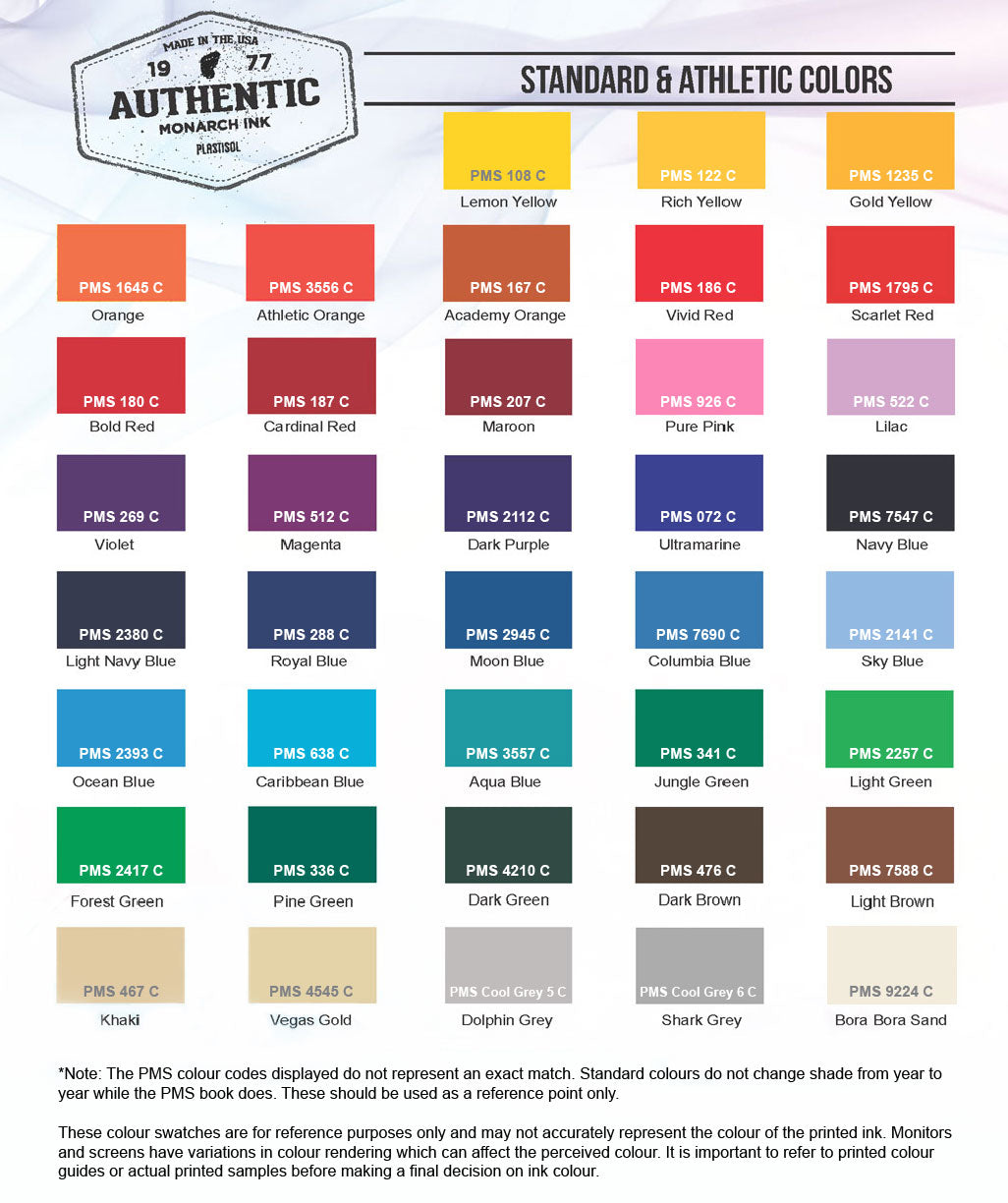

Pantone Book Series (2017 vs 2022)

- Pantone releases new PMS books on a yearly basis. Each year, some of the PMS colours in the book will change. If you are using an older book, your PMS match may be different than the more recent formulation.

Light Source (Natural, fluorescent, led)

- Light source plays a large factor in perceived visual colour and colour metamerism.

While the above factors can cause deviation in the PMS colour, the ink created from Monarch’s pigment dispersion system should be extremely consistent, meaning if you order PMS 286 C in January and then again in April, you will receive exactly the same colour match.

-

Low Cure Ink (Apocalypse LB Series)

- Creamy, short body plastisol

- High opacity and great coverage

- Good bleed resistance at a wide temperature range

- Very versatile ink

- Fast flash

- Easy to print

- Ultra soft hand

- Light weight with good drape

- Universal - print on virtually any fabric

- No under base needed on most colours

-

Standard Cure Ink (Vivid LB Series)

- Creamy, short body plastisol

- User friendly, no viscosity modifiers necessary

- Formulated to be non-phthalate

- Fast flash

- High opacity and great coverage

- Good bleed resistance

- No under base needed on most colours

-

Low Cure Ink (Apocalypse LB Series)

- Wet Ink Tack: Low

- Surface Appearance: Satin Finish

- Bleed Resistance: Good

- Opacity: High

- Gel point: 160 °F

- Flash Temp: 230° - 250°F

- Fusion Temp: 280° - 320° F

- Squeegee Blade: 70° - 80° durometer

- Mesh Count: 86 – 300 mc in

-

Standard Cure Ink (Vivid LB Series)

- Wet Ink Tack: Low

- Surface Appearance: Satin Finish

- Bleed Resistance: Good

- Opacity: High

- Gel point: 160 °F

- Flash Temp: 240° - 260°F

- Fusion Temp: 320° F

- Squeegee Blade: 70° - 80° durometer

- Mesh Count: 86 – 300 mc in

Print Monarch colours straight from the container through mesh ranging from 86 to 300 mc without modifications of the viscosity. Use finer mesh counts for softest hand and good opacity. Stir ink before use.

65°F to 95°F avoid direct sunlight. Never exceed temperatures above 95°F during storage

Stir plastisol ink before printing. Any modifiers and additives should be mixed in clean containers using clean mixer blades and ink knives. Any contamination from other ink sources could make the ink test positive for restricted phthalates. Do not dry clean, iron or bleach the printed image.

Perform fusion tests before production. Failure to cure ink properly can result in poor wash fastness, inferior adhesion, and unacceptable durability.

Adjust flash cure temperature and dwell time so ink is just dry to touch. Avoid excessive flash temperatures to protect fabric and migration of dyes. If surface is hot and tacky, the ink film has been over flashed. Reduce temperature or time to prevent an inter-coat adhesion problem.

Curing is a time and temperature process, a lower oven temperature setting with a slower belt speed while maintaining recommended ink cure temperature is always best to protect fabric, control dye migration and reduce energy consumption.

VIVID LB Colors can be cured at 320°F. Running at the higher end of the temperature range and/or longer dwell times maybe required to achieve proper cure on jobs that contain cotton, high ink deposits or heavy weight garments.

*Note: Poorly dyed polyester or too much heat in the curing process can overcome any low bleed inks ability to block the migration. For sever migration use a barrier base underlay.