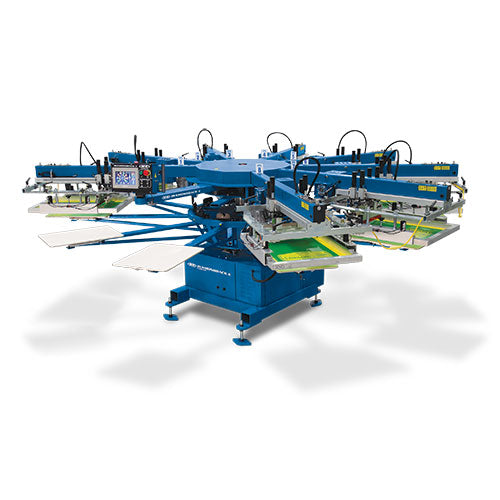

Features And Highlights

- Electric printheads provide smooth, consistent print carriage movement

- High-resolution touchscreen control panel with easy-to-use, icon-based logic and built-in tutorial screens

- Available in 6, 8 or 10 colors

Additional Information

- CAROUSEL/INDEXER SYSTEM

-

- Clockwise or counterclockwise rotation

- Freewheel capability

- Servo drive indexer provides smooth operation and durable consistency

- CENTRAL OFF-CONTACT

-

- Permits fast, incremental single-lever adjustment of all stations simultaneously

- CERTIFICATION

-

- CE & UL compliant: Built to specifications established by the European Committee for Standardization® (CE) and Underwriters Laboratories® (UL)

- CONTROL CENTER

-

- Countdown program indicates when operator-set index count has been reached

- Icon-based, high-resolution Human Machine Interface (HMI) with built-in tutorial screens

- Independent print-start/print-finish setting automatically activates and stops printheads at the beginning and end of print runs and also enables single pallet test printing

- Maintenance Minder™ System alerts operators when scheduled maintenance is due

- Multiple (1-4) print stroke capability

- Onboard self-diagnostics

- Real-time production speed monitor ensures more accurate job costing

- Selectable multi-print in the up or down position

- Swiveling control arm with multi-angle adjustable touch-screen display

- DESIGN & CONSTRUCTION

-

- Constructed from heavy-duty steel, aluminum and premium components

- Engineered and built with 30 plus years of M&R’s commitment to quality and dependability

- Heavy-duty printheads and pallet arms provide the stability necessary for exceptional screen print quality

- LASER LOCATOR SYSTEM

-

- Assists operators in the precise positioning of garments and cut pieces. See it in action!

- Speeds pallet positioning and changeover

- PALLET SYSTEM

-

- Precise three-point pallet leveling system

- Solid-aluminum, low-profile, rubber-coated pallets

- Tool-free quick release pallet locks

- PRINTHEADS

-

- Brushless, maintenance-free electric-drive motors provide smooth linear movement and exceptional control

- Four-point off-contact adjustment

- Independent print button on each printhead allows operators to print from the head location

- Independent print/flood speed controls on each printhead simplify screen printing press setup

- Independent reset button on each printhead allows operator to lower the pallets and freewheel the carousel

- REGISTRATION

-

- Compatible with M&R’s Tri-Loc® and Tri-Sync™ Rapid Registration Systems

- Precise locking micro-registration adjustments with visual guides

- REVOLVER PRINT PROGRAM

-

- Automatically operates individual printheads in programmed sequence and allows multiple flashing without losing a screen printing position

- Icon based display and logic simplifies revolver sequence programming

- SCREEN CLAMPS & HOLDERS

-

- Adjustable side frame holders accommodate a wide variety of screen sizes

- Anodized aluminum frame holders

- Clamping system holds roller frames without special adapters

- Pneumatic clamps hold frames tight and allow rapid screen loading

- SQUEEGEE/FLOODBAR

-

- Angle and calibrated pressure adjustments are independently set

- Front or rear print carriage stop position allows operator to leave screens clear or flooded (great for water-based inks)

- Independent squeegee and floodbar speed adjustments with digital display

- Independently calibrated pressure adjustments for squeegees and floodbars

- Pneumatic squeegee/floodbar clamps with tool-free calibrated angle adjustment

- Squeegee air regulator with pressure gauge on each printhead offers consistent control of print pressure

- Visual reference marks every 5 degrees simplify squeegee/floodbar angle adjustments

- STROKE LENGTH ADJUSTMENT

-

- Tool-free calibrated front & rear stroke length adjustment lets operators quickly maximize printing speeds by limiting excess image overprint

- WARRANTY, SERVICE AND SUPPORT

-

- 24-hour hotline is staffed 365 days a year

- Two-year limited warranty

- DESIGN & CONSTRUCTION

-

- Designed & disassembled to fit through a 78 cm (31") doorway

- FOOT PEDAL CONTROL

-

- Allows indexing of the press using a foot pedal

- Skip-Shirt foot pedal feature allows operators to avoid screen printing on empty pallets

- OPTICAL NO-SHIRT DETECTOR

-

- Automatically prevents the press from screen printing on empty pallets

- Reduces misprints and minimizes press stoppage because of improperly loaded shirts

- PALLETS

-

- M&R aluminum pallets and platens come in a wide range of sizes and styles

DIAMONDBACK 8/6 |

DIAMONDBACK 10/8 |

DIAMONDBACK 12/10 |

|

| Air @ 6,9 bar (100 psi) | 198 l/min (7 cfm) | 227 l/min (8 cfm) | 227 l/min (8 cfm) |

| Diameter | 340 cm (11’ 2”) | 373 cm (12’ 3”) | 406 cm (13’ 4”) |

| Electrical Requirements | 208/230 V, 1 ph, 26 A, 50/60 Hz, 3 kW 208/230 V, 3 ph, 16 A, 50/60 Hz, 3 kW 380/415 V, 3 ph, 10 A, 50/60 Hz, 3 kW |

208/230 V, 1 ph, 32 A, 50/60 Hz, 3.6 kW 208/230 V, 3 ph, 20 A, 50/60 Hz, 3.6 kW 380/415 V, 3 ph, 11 A, 50/60 Hz, 3.6 kW |

208/230 V, 1 ph, 38 A, 50/60 Hz, 4.3 kW 208/230 V, 3 ph, 26 A, 50/60 Hz, 4.3 kW 380/415 V, 3 ph, 14 A, 50/60 Hz, 4.3 kW |

| Maximum Frame Size | 58 x 84 x 5 cm (23” x 33” x 2”) | 58 x 84 x 5 cm (23” x 33” x 2”) | 58 x 84 x 5 cm (23” x 33” x 2”) |

| Maximum Image Area | 41 x 46 cm (16” x 18”) | 41 x 46 cm (16” x 18”) | 41 x 46 cm (16” x 18”) |

| Shipping Weight | 1497 kg (3300 lb) | 1819 kg (4010 lb) | 2037 kg (4490 lb) |

| Standard Pallet Size | 41 x 56 cm (16” x 22”) | 41 x 56 cm (16” x 22”) | 41 x 56 cm (16” x 22”) |

Is the Presse à sérigraphie manuelle M&R Kruzer right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Presse à sérigraphie manuelle M&R Kruzer to your apparel decorating business.