| OS | macOS® Big Sur to macOS® Monterey, Windows 8.1 (64-bit), Windows 10 (64-bit) and Windows 11 (64-bit) |

| Interface | USB2.0, LAN(10BASE-T, 100BASE-TX, 1000BASE-T), USB Flash Memory(Under 32GB, FAT32 format) |

Driver operating conditions |

2GHz CPU (minimum recommendation) 4GB RAM |

| Display resolution | XGA(1024x768) (minimum recommendation) |

| Recommended applications |

CorelDRAW® 2018/2019 (Windows), Adobe® Photoshop CS6/CC, Adobe® Illustrator CS6/CC |

FEATURES

-

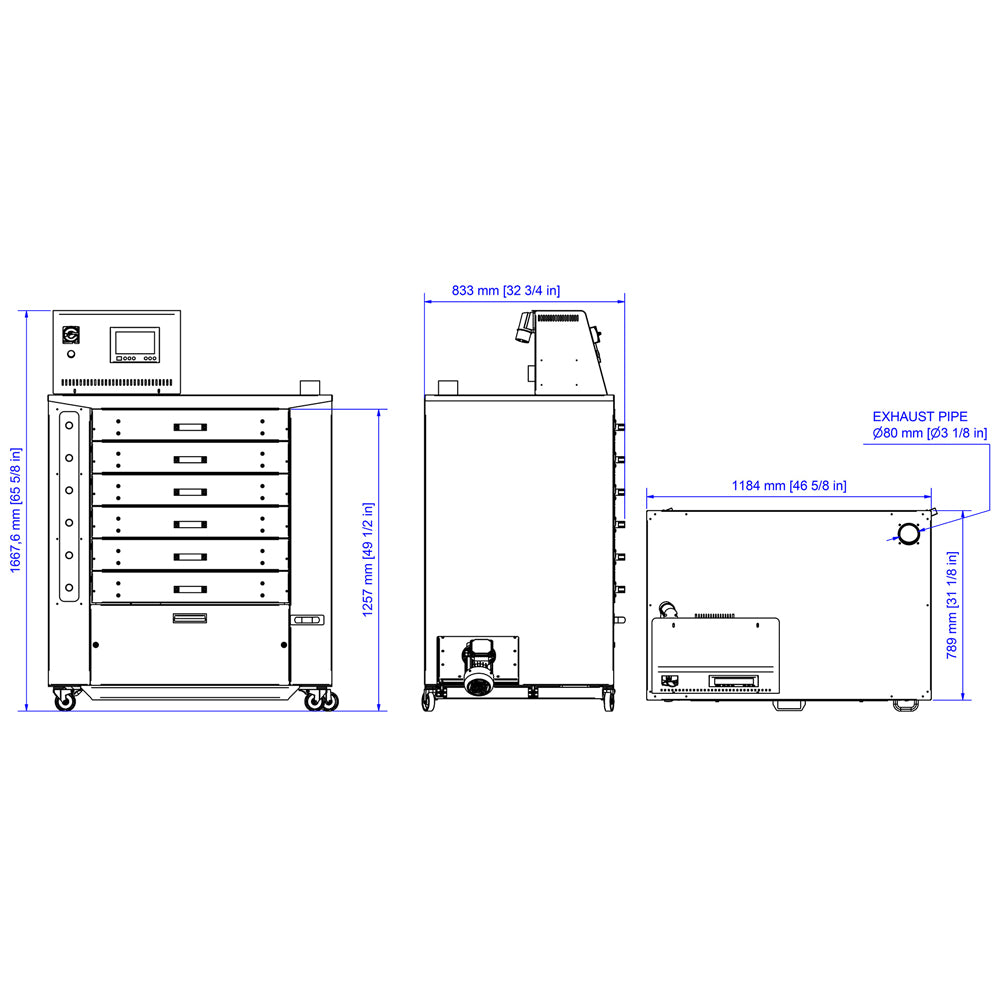

Hourly production is approximately 60 garments with a permanence of 5-6 minutes per drawer.

-

Suitable for any type of digital machines, its maximum working temperature is 180°C.

-

Each drawer is independent and equipped with its own timer, indicator light and sound alarm.

-

It works very well with medium-long drying process thanks to the control of the temperature and its efficient air circulation: for this reason it’s perfect for fine fabrics like Lycra, wool, silk and flocked garments.

-

The air is warmed by electrical heating elements and blown in a vertical convection current in order to be uniform everywhere. More so the filtered air keeps the fan and the conduct clean, improving the efficiency and power consumption of the system. The oven is equipped with exhaust fumes pipe and an heat exchanger.

-

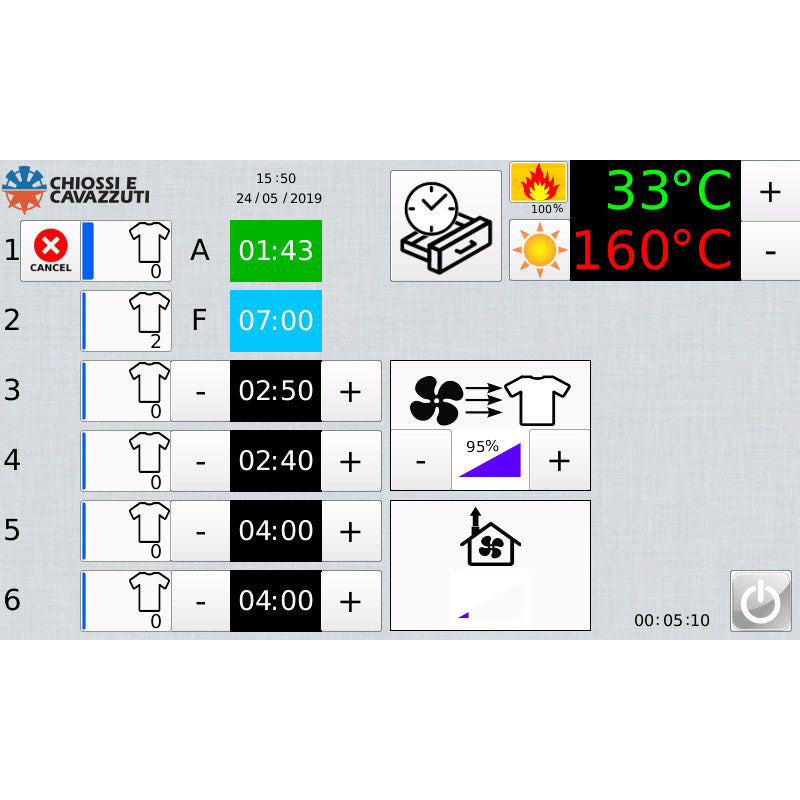

DiDO Shop dryer introduces a colored touchscreen interface, easy and interactive to use, with important new features like the automatic heating-on and switch-off of the dryer, to minimize the time lost by the operator.

TAKE FULL CONTROL OVER YOUR CURING

-

-

User friendly control panelThe latest touch-screen control panel has an easy and intuitive design. Time and temperature control are both processed digitally for precise and fast adjustments. All parameters are displayed clearly for the operator to ensure the correct curing standards are maintained.

-

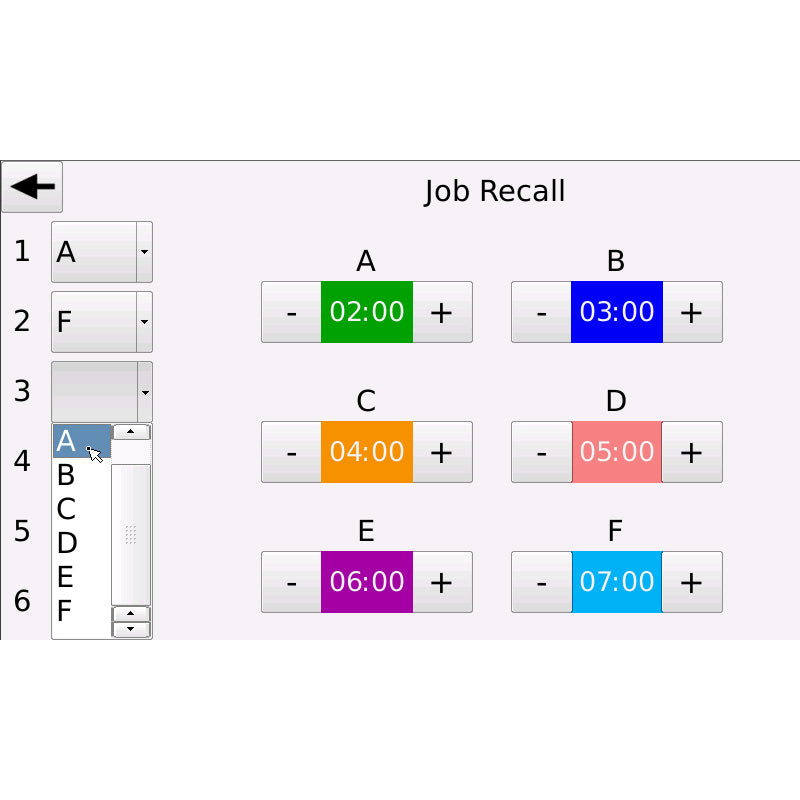

6 independent drawersThe DiDO Shop utilises a unique feature of six drawers, each with their own timer, allowing you to cure different garments or inks that have different cure times to each other. The independent drawer timers will provide maximum flexibility, they also maximise production output, no need to wait for the drawer with the slowest cure time.

-

FEATURES THAT MAKE YOUR LIFE EASIER

-

-

Easy access air filtersAir filters are located at the front of the dryer on a pull out tray, very easy to access and clean. No need to worry about down time, you can remove and clean the air filters during production.

-

Deep drawersThe DiDO Pro drawers have been designed to accommodate a wide range of garments and substrates, allowing the customer to expand into other markets easily whilst offering easy load and unload access. Mesh construction promotes airflow through the drawers resulting in "conveyor dryer results" for the compact dryer market.

-

ADVANTAGES

-

Easy And Interactive Interface

-

Automatic Scheduled Start

-

Safe Cooling Off And Sleep Mode

-

Precise Temperature Control

-

Each Drawer Has Its Own Timer

-

Drying Process Indicator Light And Alarm

-

Low Consumption Ideal For Small Business

-

Compact And Lightweight Structure

-

Unique And Uniform Air Ventilation

-

No Need For Filter Replacements

Additional Information

| Printing Method | Direct Inkjet Garment Printer |

| Machine Size | 1400mm x 1300mm x 550mm |

| Machine Weight | Approx. 120kg including Platen |

| Max. Printing Area | 16“ x 21“ (40,64cm x 53,54cm) |

| Plate Delivered | 14“ x 16“ (35,54cm x40,65cm) |

| Ink Type | Water-based pigment ink (200 and 500ml pouches available) |

| Ink Color | CMYKW |

| Ink-head type | Brother manufactured on demand piezo head |

| Number of ink-heads | 2 |

| Printhead resolution | 1200 dpi x 1200 dpi |

| Print Mode | Single or double for CMYK. Underbase and highlight for white |

| Enviroment | Operating conditions: 50°F(10°C)to 95°F(35°C) Humidity: 20-85% RH, Printing conditions: 64°F(18°C)to 86°F(30°C) Humidity: 35-85% RH |

| Data output | Printer driver (USB, File output, LAN) |

| Power supply | AC 100V-240V, 50/60Hz |

| Power consumption | 0.8A (average) (Reference: 0.4A (during circulation)) |

| Ink cure | Heat press machine can be used at 356°F (180°C) and 35 seconds duration. Conveyor oven is recommended to support high productivity of the printer at 320°F (160°C) and 3.5 minutes duration. Time and temp. may vary depending on which manufacturer‘s dryer is used. |

| Pre-treatment | Before printing, apply pre-treatment using either a manual or automatic device and then dry garment using a heat-press, being sure to follow all manufacturer‘s instructions. Pre-treatment is necessary for white ink. |

| OS | Windows 8.1 (64 bit), Windows 10 (64 bit), macOS 10.14 Mojave, macOS 10.15 Catalina |

| Interface | USB2.0, LAN (10 BASE-T, 100 BASE-TX, 1000 BASE-T), USB Flash Memory (Under 32GB, FAT32 format) |

| Driver operating conditions | 2GHz CPU, 4GB RAM |

| Display resolution | XGA (1024×768) |

| Recommended PC applications | CorelDRAW® X6/X7, Adobe® Photoshop CS6/CC, Adobe® Illustrator CS6/CC, CorelDRAW® 2018/2019 (Windows) |

Is the DiDO Pro - 6 Drawer Drying Cabinet right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the DiDO Pro - 6 Drawer Drying Cabinet to your apparel decorating business.