Additional Information

Handle under yellow safelight or low wattage tungsten lights. Avoid exposure to daylight, quartz/halogen lamps, cool white fluorescent lamps or discharge lamps.

-

DEGREASE

Using Chroma/Clean™ mesh degreaser, work up a lather on both sides of mesh. Flood screen and frame thoroughly with garden type hose, then dry.

-

PREPARE LAMINATING EMULSION

Stir or mix laminating emulsion according to instructions on emulsion user guide. Let emulsion stand at least two hours before using if diazo based.

-

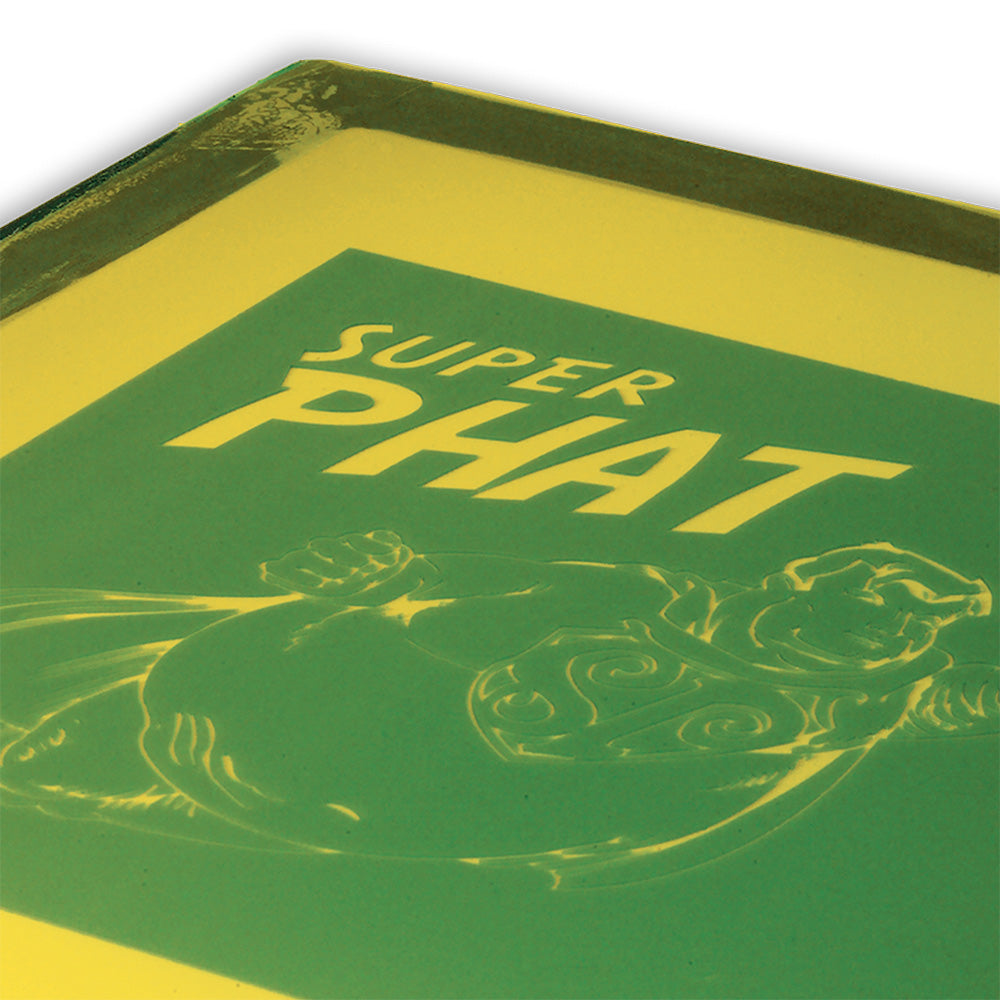

PREPARE FILM

Pre-cut the film to size, then remove the protective cover sheet. SUPER PHAT film has a protective cover sheet to help prevent pinholes by keeping dust, fingerprints and other debris from marring the film surface. TIP: The protective cover sheet can be easily removed from the film by using tape. Apply a piece of tape to the side that has a duller appearance. Then, gently pull the sheet from the film’s emulsion side.

-

COAT

Using the Direct/Indirect method, mount the film using a build-up board. Pour a bead of emulsion at one end of the screen. Using a round edge medium durometer squeegee, coat emulsion across the screen. Repeat coating up to 3 times

-

DRY

Thoroughly dry the screen using a dark, clean drying cabinet, then remove the carrier. You will know the film is dry when the carrier peels off easily. If the carrier makes any noise when being pulled off, or resists being pulled off, additional drying time is needed. Temperature should not exceed 110°F (43°C). Drying time will be approx. 1 1/2 hours. Thicker SUPER PHAT will take longer to dry.

-

EXPOSE

Place emulsion side of photopositive in contact with print side of screen. Refer to the chart below for suggested exposure times.

-

DEVELOP

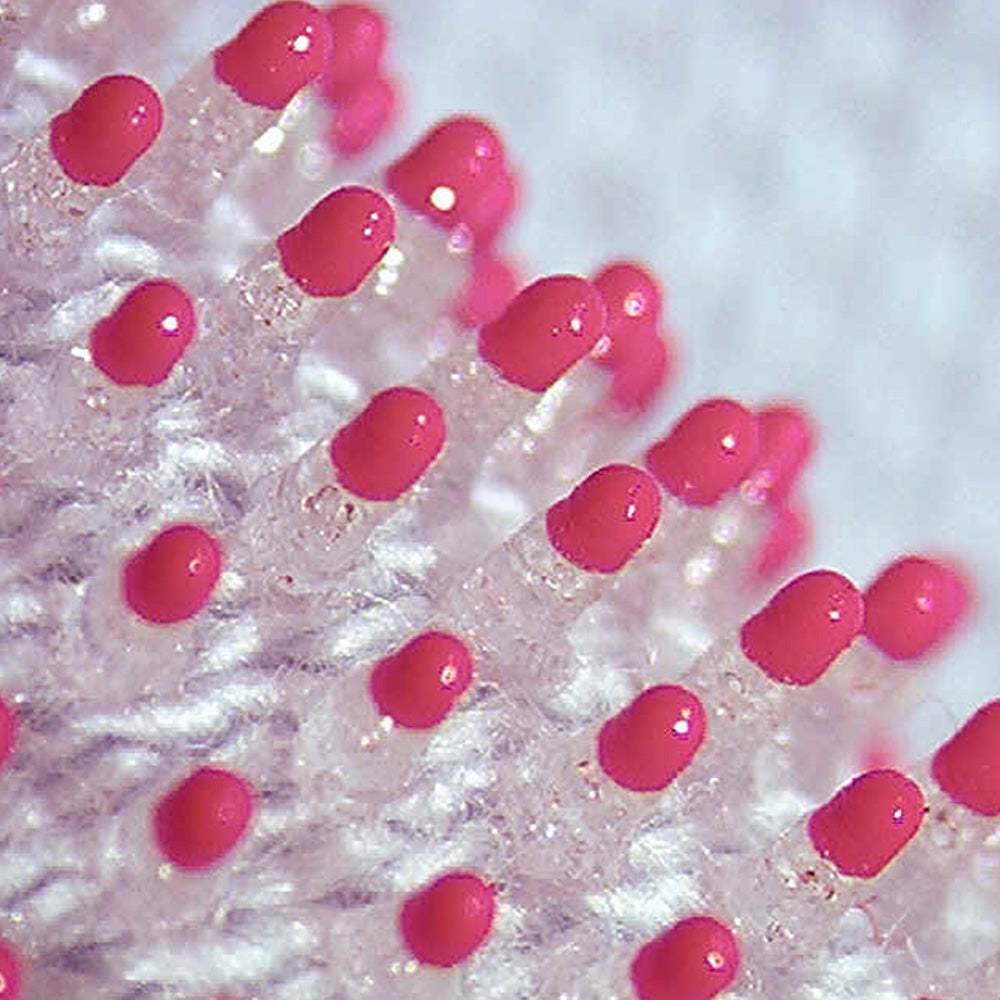

Wet both sides of screen. Begin development with high pressure washer spray on print side, until image is fully open. Typical washout can range from 2-4 minutes. NOTE: Thicker films and certain artwork may require additional washout time.

-

DRY

Once development is completed, place the stencil into the drying cabinet for approximately 15 minutes or until the stencil turns from milky white to clear. Stencil must be completely dry prior to printing.

-

RECLAIM

Reclaim by applying Chroma/Strip™ screen reclaimer to the squeegee side of screen. With a high pressure washer, spray the squeegee side of stencil. Discard any solid waste in the garbage.

-

EXPOSURE GUIDELINES

Note: Exposure times are suggested only as a guide. Perform a step test to determine proper exposure times. Individual exposure times may vary depending upon equipment used, bulb age, and other shop conditions.

| FILM THICKNESS | TIME |

| 100 | 50 sec. |

| 150 | 100 sec. |

| 200 | 150 sec. |

| 250 | 200 sec. |

| 300 | 230 sec. |

| 400 | 300 sec. |

| 700 | 550 sec. |

Exposure times were set for a 5KW unit at 40" (1 meter) from the frame using yellow mesh. *For additional processing methods and information, contact Chromaline for an interactive cd.

Shelf life is 24 months when stored at room temperature. To maximize shelf life, unexposed film should be stored in a closed container in a cool, dry area. Cut sheets must be stored flat to avoid wrinkling.

Coated, unexposed screens can be stored as long as one month in a clean, cool, dry and completely dark area.