Additional Information

-

DEGREASE

Work up a lather on both sides of mesh to degrease. Be sure to use only a high-quality mesh degreaser, such as Chroma/Clean designed specifically for this purpose. Rinse thoroughly.

-

WET

Capillary films require a thoroughly wet screen. With the screen in a vertical position, paint Chroma/Wet wetting agent onto the print side of the screen. (Use a clean brush just for this step.) Wait a moment, then flood entire screen with a garden type hose.

-

ROLL-DOWN

Reflood the screen with water and attach the roll of film to the top of the print side of the screen. With slight pressure, roll the film down until the entire piece is in contact with the mesh. Use a window squeegee to remove excess water from the squeegee side only.

-

DRY

Thoroughly dry the screen in a dark area, then remove the carrier. You will know the film is dry when the carrier peels off easily. If the carrier makes any noise when being pulled off, or resists being pulled off, additional drying time is needed. Do not exceed high temperatures of 110°F (43°C).

-

EXPOSE

After polyester carrier is removed, place emulsion side of photopositive in contact with print side of screen. Next, expose in preferred exposure unit. Run an exposure test to determine your correct exposure. (See guide at right.)

-

DEVELOP

Gently spray both sides of screen with lukewarm water. Wait approximately 30 to 60 seconds, then wash the print side of the screen until image is fully open. Rinse both sides thoroughly. Dry screen completely and you are ready to print.

-

RECLAIM

Apply Chroma/Strip screen reclaimer to both sides of screen. Scrub with a soft nylon bristle brush to ensure entire surface is wet and let it work for 30 to 60 seconds. Pressure wash out.

-

EXPOSURE GUIDELINES

Exposure times were determined by using the Chromaline Exposure Calculator. Exposure times were calculated using a 5KW unit at 40" from the frame. All screen mesh was yellow in color.

Chromaline recommends use of an exposure calculator for correct times for all equipment. These figures are only a guide.

| FILM THICKNESS | TIME |

| 40 micron | 40 - 70 sec. |

- Color: Red

- 15" x 17" Sheets

- 40 Microns - from course to thin mesh

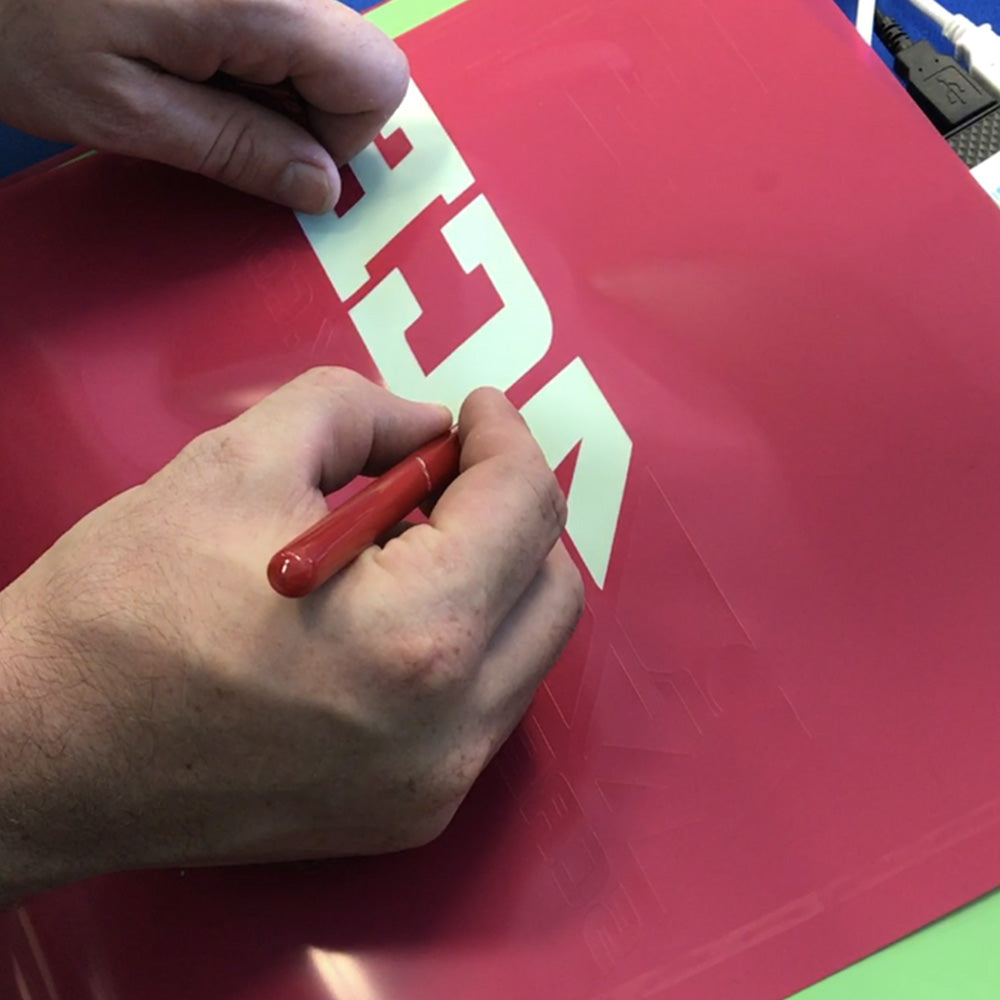

- Control Quality

- Quicker to Press

- No Pinholes

- No Waste

- 2 Year Shelf Life

- Use with a Plotter Cutter - watch video here

Quick Film should be stored at room temperature and should not be stored at temperatures above 80°F (27°C) or below 32°F (0°C). Film degrades quickly if stored above 110°F.

Pre-Sensitized Quick Films are light sensitive. Open under yellow or subdued lighting. Storage recommendation: Unexposed film should be sealed in original container.

Coated, unexposed screens can be stored up to one month in a clean, dry and completely dark area.